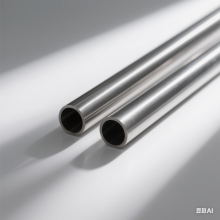

ZHONGZHENG is your trusted supplier and exporter of Stainless Steel 904L Tube that is a fully austenitic low-carbon variety of stainless steel with additives of molybdenum and copper. Our range of SS 904L Tubes is specially designed using the premium quality material to resist heavyweights and pressure conditions. Our offered 904l grade tubes available in the various form of round, rectangular and are in compliance with ASTM B677, ASTM B673, ASTM B674 standards.

904L Stainless Steel Tubes or UNS N08904 Tubes is a ferritic, non-heat treatable stainless steel tubes that feature good resistance and corrosion properties to high-temperature applications. Stainless Steel 904L also has excellent resistance to chloride attack – pitting/crevice corrosion and stress corrosion cracking.

We offer a diverse range of Stainless Steel 904L Seamless Tubes is most commonly used in applications with elevated temperatures between 1500 to 2100 °F. However, SS 904L Welded Tubes are heat resistant stainless steel tube that can tolerate molten copper, lead, tin, and brass.

Moreover, our Stainless Steel 904L Cold Drawn Tubes and Stainless Steel 904L Electropolished Tube are provided in a combination of good grades, thickness, length, and surface finish. Please do contact us today to request a competitive quote on Grade 904L tubes or any other stainless steel tubes. Hurry up!

DIN 1.4531 Stainless Steel Welded Tubes, 904L SS Tubes Dealer, ASME SB 674 SS 904L Tubing, Stainless Steel 904L Hydraulic Tube, SS 904L Rectangular Tube, SS 904L Electropolished Tube Wholesalers & Stockists