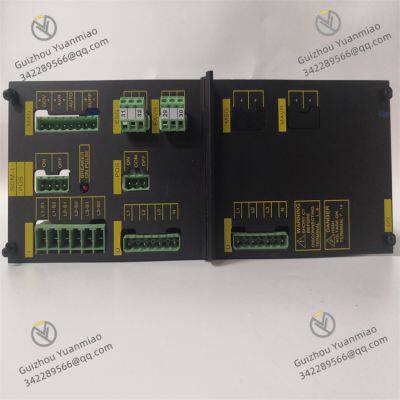

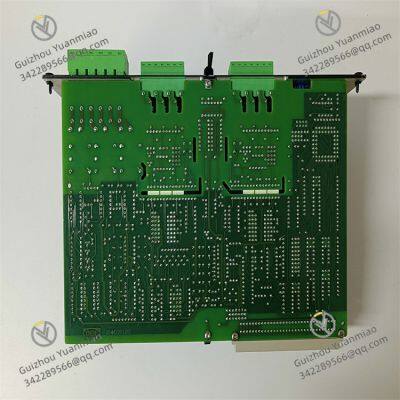

DEIF DELOMATIC-3 Printed Circuit Board

The DELOMATIC-3 is primarily used to detect fault conditions and trigger circuit breaker tripping to prevent damage to power equipment such as generators and transformers. It can be widely applied in industries such as power generation, marine, and industrial automation.

Functional Features

Technical Parameters

Working Principle

Common Fault Categories and Solutions

1. Unit Fails to Start

2. Unstable Voltage/Frequency

3. Communication Failures (e.g., Modbus, CANopen)

4. Overload or Short Circuit Protection Activation

Send Inquiry to This Supplier

You May Also Like

-

EMG ECU01.5 ECU01 Analog Input ModuleNegotiableMOQ: 1 Piece

-

UNIOP ETT-VGA-0045 Industrial Display ModuleNegotiableMOQ: 1 Piece

-

PACIFIC SCIENTIFIC H32NCHA-LNN-NS-00 Servo Drive ModuleNegotiableMOQ: 1 Piece

-

Bender IRDH275B-435 Insulation MonitorNegotiableMOQ: 1 Piece

-

INDEL INFO-4KP-94161B Positioning PlateNegotiableMOQ: 1 Piece

-

KOKUSAI KOMS-A2 CXP-544A Industrial CPU BoardNegotiableMOQ: 1 Piece

-

KOKUSAI SMPCONT-A3B Control ModuleNegotiableMOQ: 1 Piece

-

ELAU MAX-4 ControllerNegotiableMOQ: 1 Piece

-

Alcatel-Lucent M10-1GB-SFP-B Small Pluggable Optical ModuleNegotiableMOQ: 1 Piece

-

Dialogic DMV2400A-CPCI Digital Media Processing Board CardNegotiableMOQ: 1 Piece