Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Output Load

Maximum 750Ω

Input Voltage

24V DC ±5%

Resolution

13 bits

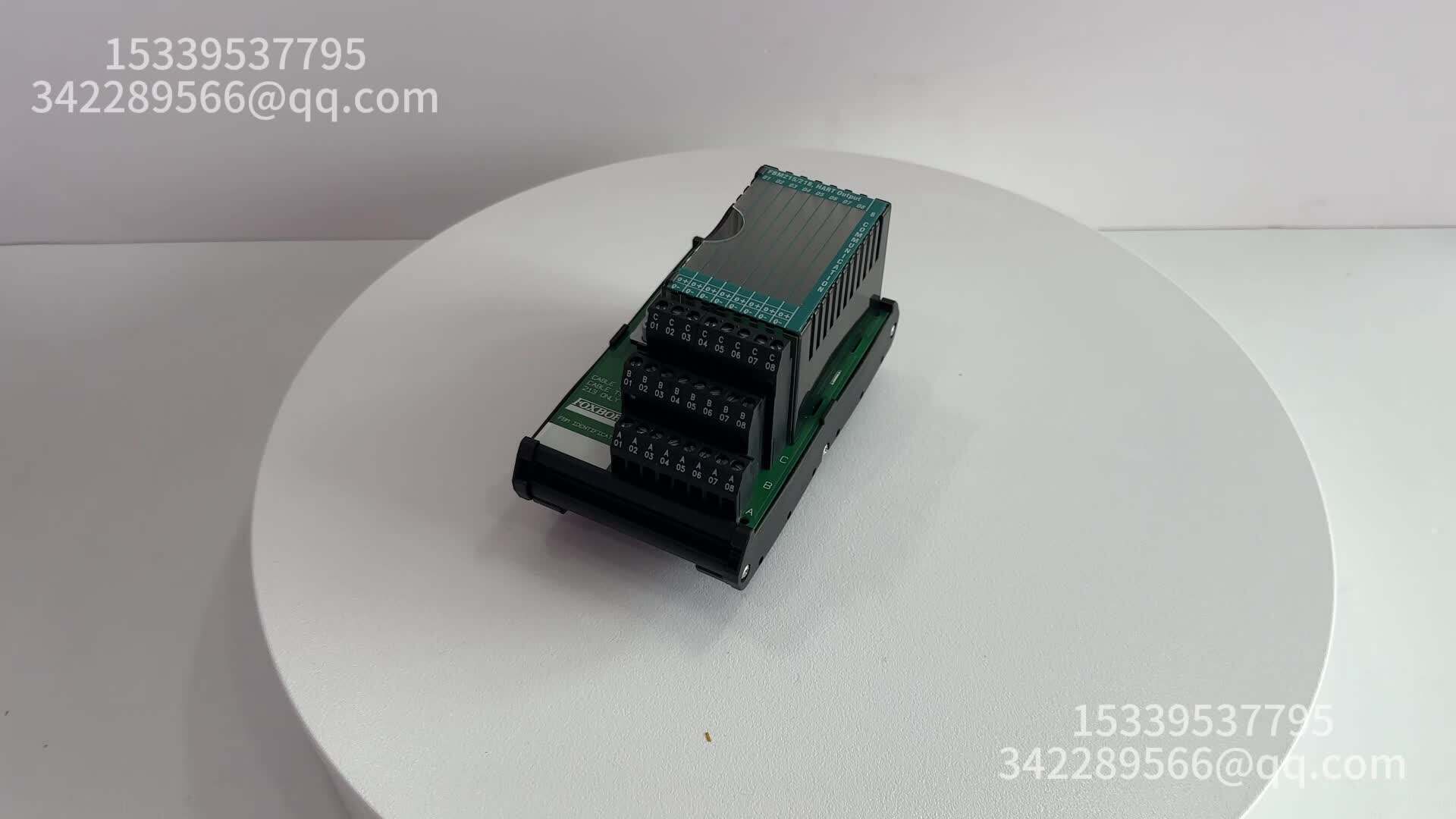

Foxboro FBM215 P0917TQ

Functional Features

Output Channels: 8 isolated output channels, each providing standard 4-20mA analog output signals or digital HART frequency shift keying (FSK) signals superimposed on 4-20mA analog outputs. It supports any combination of standard 4-20mA devices and HART devices.

Communication Capability: Acts as a HART communication field device master, enabling the Foxboro™ DCS to request and receive two digital messages per second from field devices. Each output channel is equipped with a dedicated FSK modem for two-way digital communication with HART field devices, supporting HART universal commands to interface field devices with the Foxboro DCS database.

Electrical Isolation: All output channels are electrically isolated from each other, ground, and module logic, enhancing system stability and anti-interference capability.

Environmental Adaptability: Housed in a rugged extruded aluminum case, suitable for G3-level (harsh) environments. It operates at -20 to +70°C, 5-95% relative humidity (non-condensing), and withstands 7.5m/s² (0.75g) vibration at 5-500Hz, meeting various industrial environment requirements.

Visual Indicators: Front-panel light-emitting diodes (LEDs) intuitively display the module's operating status and channel communication activities for easy monitoring and fault troubleshooting.

Technical Parameters

Analog Accuracy: ±0.05% of full scale (between 4mA and 20mA).

Output Load: Maximum 750Ω.

Maximum Change Rate: 20mA within 60 milliseconds.

Resolution: 13 bits.

Input Voltage Range (Redundant): 24V DC ±5%.

Power Consumption: 7W (maximum).

Heat Dissipation: 5W (maximum).

Maximum Distance: Complies with HART FSK physical layer specification HCF_SPEC-54, Edition 8.1, up to 3030 meters (10000 feet).

Application Fields

This module is a key component in building industrial automation systems, suitable for industries such as power, petroleum, chemical, natural gas, metallurgy, cement, papermaking, mining, light textiles, food, and medicine. It meets the high-precision and high-reliability requirements of these industries for industrial automation control.

Foxboro FBM215 P0917TQ Module Fault Troubleshooting GuideI. Module Basic Information and Application Scenarios

The Foxboro FBM215 (P0917TQ) is a Fieldbus Module under Emerson, belonging to the I/O module of the DeltaV control system, mainly used for processing analog input signals (such as temperature, pressure, flow, etc.). Its typical features include:

8-channel differential analog input with 16-bit resolution;

Compatible with HART protocol for communication with smart transmitters;

Equipped with channel isolation and diagnostic functions, suitable for industrial process control scenarios.

II. Fault Troubleshooting Process and Methods(1) Hardware Connection and Power Check

(2) Indicator Lights and System Diagnostics

(3) Signal Input and Channel Fault Troubleshooting

(4) HART Communication Fault Handling

HART Function Check

Whether the signal wire supports HART (needs to be twisted pair, length ≤1.2km);

Whether the loop impedance is within the specified range (typically 250-600Ω).

Confirm that the module's HART configuration is correct (e.g., address, protocol version). Read transmitter data via the DeltaV system or HART handheld device (e.g., Rosemount 375).

If HART communication fails, check:

(5) Software and Configuration Issue Troubleshooting

III. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|

| Module without power | Power adapter failure, cable break | Replace the power supply, repair the cable |

| Communication Interruption COM light off | Network cable failure, controller fault | Replace the network cable, restart the controller or module |

| Data jump or distortion in a channel | Signal interference, transmitter fault | Add shielding grounding, replace the transmitter |

| System error "channel open" | Input cable disconnected, terminal poor contact | Check terminal connections, re-crimp or weld |

| HART cannot read transmitter data | Address conflict, communication protocol mismatch | Reset HART address, confirm protocol parameters |