Pepperl+Fuchs Inductive sensors

- T/T L/C PayPal D/P Western Union Other

You May Like

Product Details

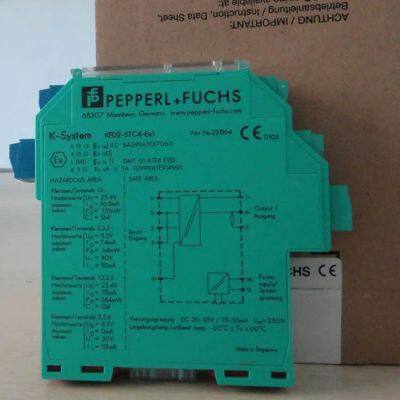

| Brand Name | Pepperl+Fuchs |

Product Description

Pepperl+Fuchs Inductive Sensors in the Packaging Industry: Enhancing Efficiency and Reliability

In the fast-paced and highly competitive packaging industry, precision, efficiency, and reliability are paramount. Packaging processes must ensure that products are securely contained, labeled accurately, and transported safely to their destinations. P+F inductive sensors play a crucial role in achieving these objectives, offering a range of benefits that enhance the performance and productivity of packaging lines. This article explores the applications, advantages, and future trends of Pepperl+Fuchs inductive sensors in the packaging industry.

1. Introduction to Pepperl+Fuchs Inductive Sensors

Pepperl+Fuchs, a global leader in automation technology, offers a comprehensive range of inductive sensors designed to meet the diverse needs of industrial applications. Inductive sensors operate based on the principle of electromagnetic induction, detecting the presence or absence of metallic objects without physical contact. This non-contact detection method ensures high precision, fast response times, and long-term reliability, making inductive sensors ideal for use in the packaging industry.

High Precision: P+F inductive sensors provide accurate and repeatable detection of metallic objects, ensuring precise positioning and control in packaging processes.

Fast Response Times: With rapid response times, these sensors can quickly detect changes in the position or presence of objects, enabling high-speed packaging operations.

Durability: Built to withstand harsh industrial environments, P+F inductive sensors are robust and resistant to wear and tear, ensuring long-term reliability and reducing maintenance costs.

2. Key Features of Pepperl+Fuchs Inductive Sensors

Pepperl+Fuchs inductive sensors come with several key features that enhance their performance and usability in the packaging industry:

Wide Sensing Ranges: These sensors offer a variety of sensing ranges, allowing for flexible installation and detection of objects at different distances. This versatility is particularly useful in packaging lines where space constraints and varying object sizes are common.

High Switching Frequencies: P+F inductive sensors can operate at high switching frequencies, enabling them to keep up with the fast-paced nature of packaging processes. This ensures that the sensors can accurately detect objects even at high speeds.

Temperature and Chemical Resistance: Many P+F inductive sensors are designed to withstand high temperatures and exposure to chemicals, making them suitable for use in environments where packaging materials may emit heat or contain corrosive substances.

Easy Integration: These sensors are available with various output options and mounting configurations, facilitating easy integration into existing packaging systems. This reduces installation time and costs, and ensures compatibility with a wide range of automation components.

Advanced Diagnostics: Some P+F inductive sensors feature advanced diagnostic capabilities, enabling quick troubleshooting and maintenance. This helps in minimizing downtime and ensuring smooth operation of the packaging line.

3. Benefits of Using Pepperl+Fuchs Inductive Sensors in the Packaging Industry

Using Pepperl+Fuchs inductive sensors in the packaging industry offers several benefits, including:

Improved Productivity: By providing precise and reliable detection, inductive sensors help in increasing the speed and efficiency of packaging processes. This leads to higher throughput and reduced cycle times, improving overall productivity.

Enhanced Product Quality: Inductive sensors ensure accurate positioning, filling, and labeling, leading to consistent product quality. This helps in meeting customer expectations and maintaining brand reputation.

Reduced Downtime: The durability and reliability of P+F inductive sensors reduce the risk of breakdowns and maintenance issues, minimizing downtime and ensuring smooth operation of the packaging line.

Cost Savings: By improving productivity and reducing waste, inductive sensors help in lowering operational costs. Additionally, their long-term reliability reduces the need for frequent replacements, further contributing to cost savings.

Compliance with Regulations: In industries where packaging must comply with strict regulations, such as pharmaceuticals or food and beverage, inductive sensors help in ensuring that products are packaged and labeled accurately, meeting regulatory requirements.

4. Future Trends and Innovations

As the packaging industry continues to evolve, there is a growing demand for more advanced and efficient automation solutions. Pepperl+Fuchs is at the forefront of this innovation, constantly developing new technologies to meet the changing needs of customers. Here are some future trends and innovations to watch for:

Smart Sensors: Pepperl+Fuchs is exploring the integration of smart features into its inductive sensors, enabling them to perform more complex tasks and communicate with other devices and systems. This would allow for real-time data transmission, remote monitoring, and predictive maintenance, further enhancing the efficiency and reliability of packaging processes.

Miniaturization: As packaging machinery becomes more compact, there is a need for smaller and more lightweight sensors. Pepperl+Fuchs is developing miniaturized inductive sensors that maintain high performance and reliability, enabling more flexible and efficient system designs.

Enhanced Diagnostics: Future inductive sensors may feature advanced diagnostic capabilities, providing more detailed information about the sensor's status and performance. This would enable quicker troubleshooting and maintenance, further reducing downtime and improving productivity.

Pepperl+Fuchs inductive sensors have revolutionized the packaging industry, providing precise control, efficient operation, and enhanced reliability in various applications. Their key features, such as high precision, fast response times, and durability, offer numerous benefits to users, including improved productivity, enhanced product quality, and reduced downtime.

Contact Us

- Ningbo Yuantao Import&Export Co.,Ltd.

- Contact nameNick Xu Chat Now

- AddressYinzhou District, Ningbo, Zhejiang

New Products

-

ABB Drives

-

ABB Soft starters

-

ABB Motors

-

Siemens Soft starters

-

Siemens Variable Frequency Drives

-

Siemens Motors

-

Schneider Variable speed drives

-

Schneider Soft Starters

-

Schneider Circuit Breakers

-

Schneider Contactors

-

Emerson Coriolis flowmeters

-

ENHCPASSY800

Popular Searches

- dust sensor

- pir sensor

- photo sensor

- car sensor

- pressure sensor

- truck sensor

- abs sensor

- speed sensor

- abs wheel speed sensor

- camshaft position sensor

- crankshaft position sensor

- oil pressure sensor

- map sensor

- automatic door sensor

- auto sensor

- magnetic sensor

- powerful transducer

- ultrasonic transducer

- touch switch

- sound control switch

- detector switch

- photocell

- microwave sensor

- photoelectric switch

- sensor switch

- thermister

- automatic sensor

- sensing

- heat sensor

- frequency converter

Recommended Products

- MS4525DO-DS5AI001DP digital output pressure sensor

- DLVR-L10D-E1BD-I-NI3N Airspeed sensors, flight control products, unmanned aerial vehicle pressure sensors, all sensors

- Danfoss Pressure switch, KP36 060-214466

- Danfoss Thermo. operated water valve, AVTA 10, G, 3/8 003N1132

- Danfoss Fluid control EVA210A 032H8000 Solenoid valve, EV210A, Function: NC, G, 1/8, 0.04 m³/h, EPDM

- Danfoss sensor temperature MBT113/120/110/100 MBT150

- DANFOSS SENSOR-PRESSURE MBS3050 MBS3100

- Danfoss MBS2050/2150/2200/2250/MBS3000

- Danfoss sensor-pressure 084G4142

- GE Industrial Vibration Transmitter 344A9322G001

- Brand new original GE vibration sensor 344A9322G001

- Datasheet-Danfoss-MBS-4010-Pressure-Transmitter

Find Similar Products By Category

- Electrical & Electronics > Sensor > Pressure Sensor

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Nick Xu

Hi there! Welcome to my shop. Let me know if you have any questions.

Nick Xu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile