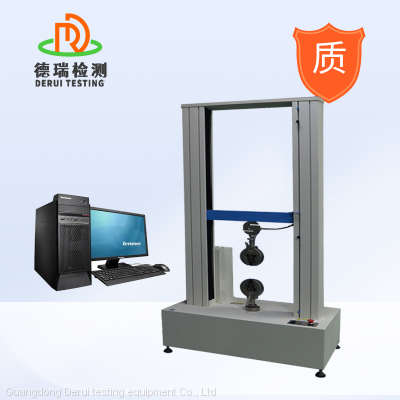

Tensile Strength Testing Machine With Fast Delivery and After-Sales Service

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) | |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection | |

| Upper and lower limit switches | |

| Load sensor with automatic retreat |

Tensile Strength Tester with Real-time Force Monitoring Product Introduction

In the field of material property testing, the need for precise control of force during testing and real-time data feedback is becoming more and more critical. Our tensile strength testers are equipped with advanced real-time force monitoring function, with excellent performance, cutting-edge technology, to provide accurate and efficient tensile strength testing solutions for various industries.

I. Real-time force monitoring function details

High-precision force sensor real-time capture: the tester is equipped with ultra-sensitive force sensor, which can capture the change of force value of the material in the tensile process in real time with very high precision. The force measurement accuracy can reach ±0.5% FS (full scale), which can be accurately sensed whether it is a small force fluctuation or a strong force change under high load. For example, when testing materials used to connect precision electronic components, the sensors are sensitive to the forces exerted on the material under small tensile forces, providing accurate data for evaluating the reliability of the material connection.

High-speed data transmission and display: The data collected by the force sensor is rapidly transmitted to the device's intelligent control system via a high-speed data transmission line. On the high-definition display of the operation interface, the force data is presented in a real-time dynamic manner, with an update frequency of up to tens of times per second. The operator can intuitively and clearly observe the change curve of the force value with time during the stretching process of the material, as if witnessing the evolution of the material's force, which provides a powerful support for timely adjustment of the test parameters and accurate judgment of the material's performance.

Abnormal force value warning function: The control system with built-in intelligent algorithm has the function of abnormal force value warning. By analyzing the real-time force data, the system can automatically identify abnormal force conditions that occur during the test, such as sudden changes in force values and exceeding the preset range. Once the abnormality is detected, the system immediately sends out sound and light alarm signals to remind the operator to deal with it in time. This function is especially important when testing high-strength, high-risk materials, which can effectively avoid equipment damage and safety accidents caused by sudden breakage of materials or other abnormal situations.

Second, based on real-time force monitoring performance advantages

Accurate test results guarantee: real-time force monitoring function ensures the accuracy and completeness of the force data during the entire testing process. Testers can accurately control the loading speed and loading volume according to the real-time feedback of the force value, avoiding the deviation of test results caused by improper loading. For example, when testing the yield strength of metal materials, the real-time observation of force value changes can more accurately determine the yield point of the material, thus producing more accurate yield strength values and providing a reliable basis for material performance evaluation.

In-depth analysis of material properties: Continuous and real-time force monitoring data provides abundant information for in-depth analysis of material properties. Through the study of the force value change curve, not only can we obtain the material's tensile strength, yield strength and other conventional mechanical property indexes, but also further analyze the deformation behavior, toughness characteristics and fatigue performance of the material in different stress stages. For example, when studying the fatigue performance of rubber materials, the force - time curve drawn based on real-time force monitoring data can clearly show the material's force decay during multiple cycles of loading, providing key data for assessing the service life of rubber materials.

Improve test efficiency and safety: The abnormal force warning function can detect problems in the test process in time, avoiding ineffective testing and equipment damage, thus improving test efficiency. At the same time, real-time force monitoring enables operators to grasp the progress of testing and the state of materials in real time, and take prompt measures in case of abnormalities to ensure the safety of the testing process. For example, in the high-load tensile testing of large structural materials, once the force value is abnormal, the operator can immediately stop the test to avoid equipment damage and personnel injury caused by the sudden fracture of the material.

Send Inquiry to This Supplier

You May Also Like

-

Tensile Strength Test Machine With Customizable Options - Tailored to Your NeedsUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine for Quality Control Managers - Fast Results and Easy ReportingUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine With Custom Test Programs - Tailored to Your SpecificationsUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine With One-Button OperationUS$ 3999 - 9999MOQ: 1 Set

-

CE Certified Tensile Strength Test Machine - Meet European Safety StandardsUS$ 3999 - 9999MOQ: 1 Set

-

CE Certified Tensile Strength Test Machine - Meet European Safety StandardsUS$ 3999 - 9999MOQ: 1 Set

-

CE UL Listed Vertical Combustion Tester for Plastics & ElectronicsUS$ 2000 - 3000MOQ: 1 Set

-

ASTM D635 Vertical Combustion Tester With Data Logging FunctionUS$ 2000 - 3000MOQ: 1 Set

-

IEC 60695 Vertical Combustion Tester for Electrical ComponentsUS$ 2000 - 3000MOQ: 1 Set

-

UL 94 V-0 Vertical Combustion Tester for Flame Retardant MaterialsUS$ 2000 - 3000MOQ: 1 Set