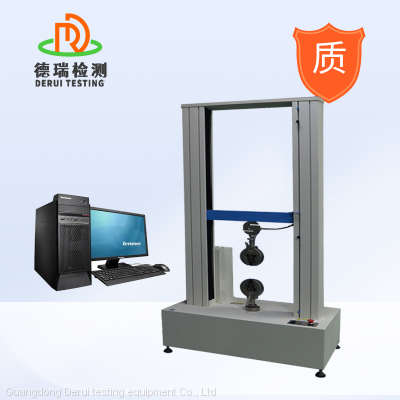

CE Certified Tensile Strength Test Machine - Meet European Safety Standards

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) | |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection | |

| Upper and lower limit switches | |

| Load sensor with automatic retreat |

Tensile Strength Testing Machine: Solve Material Testing Challenges Across Industries

Tensile testing is a cornerstone of material performance evaluation, yet many businesses struggle with inefficiencies, compliance hurdles, and suboptimal testing accuracy. With the right tensile strength testing machine, manufacturers and quality control teams can streamline processes, ensure compliance with global standards, and achieve unprecedented efficiency.

1. Identify the Pain Points in Tensile Strength Testing

Material testing is not one-size-fits-all. Industries face unique challenges when conducting tensile tests,:

Slow Testing Speeds: Does your testing process delay production schedules or lead to bottlenecks?

Standard Compliance Challenges: How do you ensure your test results meet the growing number of international standards (e.g., ASTM D638, ISO 527)?

Material-Specific Testing Needs: Materials like rubber, thin films, or composite structures demand precise load control, temperature simulation, and advanced grips.

Inconsistent Test Data: Are you encountering discrepancies caused by uncalibrated machines or outdated sensors?

These issues not only reduce operational efficiency but also risk compliance failures, impacting product reliability and market competitiveness.

2. Industry-Specific Solutions: Testing Made Smarter

Addressing these challenges requires tailored solutions. Below are real-world applications of tensile testing machines across industries, demonstrating how they can simplify workflows and enhance precision.

Aerospace Industry: Testing Composite Materials for Structural Integrity

Aerospace components, such as carbon fiber reinforced polymer (CFRP) frames, require advanced tensile testing to verify both strength and fatigue performance.

Solution: Use a high-precision tensile strength testing machine equipped with automated load control and temperature simulation modules (-40°C to 150°C). This ensures reliable simulation of high-altitude conditions, reducing the risk of material failure in extreme environments.

Key Features:

Compliance with ASTM D3039 (composite tensile strength).

Fast data acquisition speed (5 kHz) enables accurate capture of creep and stress relaxation behaviors.

Electronics Industry: Testing Connector Pins and PCB Components

Plastic connectors and solder joints in the electronics industry are prone to cracking or breaking under thermal and mechanical stress.

Solution: Use a tensile machine with programmable load paths to test connector pins repeatedly under bending and torque conditions.

Key Features:

Simulate thermal cycling (0°C to 85°C) to study material performance in real-world conditions.

Compatibility with multi-pin samples, reducing the need for manual reconfigurations.

Packaging Industry: Simulating Environmental Stress on Plastic Films

Plastic films used for food or medical packaging require extensive quality checks to ensure resistance to tearing and punctures under different conditions.

Solution: A tensile testing solution with environmental simulation can replicate humidity and temperature extremes to test material durability during storage and transit.

Key Features:

Integrated humidity control (RH 10%-95%) for packaging materials.

Customizable test speeds (e.g., 10 mm/min for tensile mode, 1,000 mm/min for puncture resistance).

3. Real-World Example: Tensile Machine Testing in Action

Case Study 1: Automotive Industry

A leading automotive manufacturer sought to validate the tensile strength of anodized aluminum sheets utilized for lightweight car frames. By integrating our tensile testing machine, equipped with:

Auto calibration for repeatable results under varied load settings.

Advanced multi-axis load sensors capable of capturing micro-deformations.

Results:

Testing cycle times reduced by 70%, achieving 5x efficiency gain.

Increased component reliability, cutting warranty claims by 20%.

Case Study 2: Electronics Industry

A connector manufacturer needed to test PCB solder joints experiencing frequent failures under variable temperatures. Implementing a tensile testing machine with dynamic load paths enabled:

Repeatable stress application at -20°C to 85°C in 15-second intervals.

Enhanced traceability through report templates meeting IPC industry standards, resulting in a 45% reduction in R&D feedback loops.

Case Study 3: Packaging Industry

A multinational packaging company aimed to improve the durability of its seals under tropical distribution conditions. The use of temperature-controlled tensile testers supported:

Rapid creation of tailored load-deformation profiles.

Successful launch in 7 new overseas markets, thanks to seamless compliance testing.

4. Choosing the Right Tensile Strength Testing Machine for Maximum Value

Selecting the ideal tensile testing machine requires a balance between technical performance and operational practicality. Here’s what to prioritize:

Essential Features to Look For:

Test Standards Compliance: Ensure the machine supports certifications like ASTM D638, ISO 527, EN 10002-1, and others relevant to your industry.

Customizable Programming: Look for machines that allow drag-and-drop test scripts to handle complex load paths, such as multi-step tension-compression cycles.

Real-Time Data Integration: Choose a machine that connects seamlessly with LIMS (Laboratory Information Management Systems) or ERP software to minimize manual data entry.

Safety and Reliability: Seek machines featuring IP-rated protection modules against dust and moisture and redundancy in load sensors for fault tolerance.

What Sets Our Tensile Tester Apart?

Our machine combines customizability, international compliance, and real-time insights:

Up to 20% faster testing cycles due to optimized load paths.

100% report automation supported by TÜV-certified sensors for faster client approvals.

5. Action Plan: Start Optimizing Your Testing Today

By upgrading to a versatile tensile testing machine, businesses across industries can accelerate innovation cycles and enhance market competitiveness.

Here’s how to get started:

Evaluate Your Needs: Identify your most time-consuming testing steps and ensure the machine supports those workflows.

Request a Custom Demo: Schedule time to test our equipment with your samples, and witness test output live.

Explore Free Resources: Download our Ultimate Guide to Tensile Testing or speak to one of our industry experts for free.

Click below to speak with our team and learn why thousands of businesses trust us to streamline their tensile testing.

[Request a Callback] [Download Case Studies]

Technical Specifications at a Glance

Features Value

Load Range 5 kN – 200 kN

Test Speed 0.001–500 mm/min

Environmental Control -40°C to 150°C (optional)

Accuracy ±0.1% FS

Measurement Resolution Laser displacement: 0.1 μm

Certifications CE, ISO 17025, TÜV

Why Choose Us for Tensile Testing Machines?

Over 15 years of innovation in materials testing.

Certified compliance with global safety and testing standards.

50,000+ successful test installations worldwide.

Your Tensile Strength Testing Machine, Simplified

From reducing your testing cycles by 70% to ensuring full compliance with regional and international standards, our customizable tensile strength testing machines bring precision and efficiency to every workspace.

Send Inquiry to This Supplier

You May Also Like

-

EN 60335 Vertical Combustion Tester for Household Appliance SafetyUS$ 2000 - 3000MOQ: 1 Set

-

UL 1581 Vertical Combustion Tester for Wire & Cable InsulationUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Automotive Interior Materials TestingUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Furniture Upholstery Flame ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Children's Toy Safety ComplianceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester 100mm×100mm Sample Size for IEC 60695US$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester CE Marked for EU Market ComplianceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Silicone Rubber FlammabilityUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester With PLC Control SystemUS$ 2000 - 3000MOQ: 1 Set

-

CE ISO 17025 Certified Image Measuring Instrument for Precision MetrologyUS$ 3000 - 5000MOQ: 1 Set