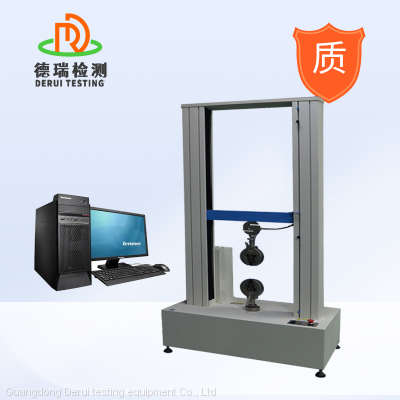

Tensile Strength Test Machine for Quality Control Managers - Fast Results and Easy Reporting

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) | |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection | |

| Upper and lower limit switches | |

| Load sensor with automatic retreat |

Tensile Testers for Quality Control Managers - Fast Results and Easy Reporting

In the highly competitive manufacturing industry, quality control managers need fast, reliable material testing data to support decision making. Our intelligent tensile tester is designed for quality control scenarios, helping companies realize the whole process of quality control from incoming raw materials to outgoing finished products by improving testing efficiency by 30% and generating reports at the touch of a button.

I. Core Quality Control Advantages

1. Extremely fast testing process

10 seconds fast clamping: pneumatic fixture automatically recognizes the sample type, no need for manual adjustment.

Intelligent parameter recommendation: after inputting the material type, the system automatically matches the best test parameters.

Unattended testing: supports 10 groups of samples for continuous testing, and automatically executes the test queue at night.

2. Real-time quality judgment

Dynamic over-limit warning: real-time comparison of preset tolerance ranges during testing, and automatic shutdown when exceeding the tolerance.

CPK process capability analysis: automatically calculate the process capability index, generate SPC control charts

Defect pattern recognition: AI algorithm analyzes the fracture pattern and locates the weak links in the process.

3. One-click reporting system

3-minute report generation: built-in 20+ industry standard report templates (including corporate LOGO)

Multi-format export: Support PDF/Excel/XML format, compatible with ERP/MES system.

Electronic Signature Certification: Compliant with FDA 21 CFR Part 11 electronic record specification

Typical Quality Control Scenarios

1. Raw material incoming inspection

Plastic particles: 3 minutes to complete the tensile strength test, automatic generation of incoming material inspection report.

Sheet metal: real-time display of stress-strain curve, quickly determine the stability of the material batch

Composite materials: AI analyzes the peel strength between layers and identifies defects in adhesive coating.

2. Production process monitoring

Automotive fasteners: 3 tests per minute, CPK values updated in real time.

Electronic components: 0.01mm ultra-thin sample testing, locate welding process problems

Medical devices: automatic identification of abnormal fluctuations in penetration force, traceability of the production process.

3. Finished product factory inspection

Packaging materials: 2 minutes to complete the peel strength and impact resistance test.

Reinforcing steel: automatic determination of strength level, test results are directly connected to BIM system.

Aerospace components: Generate test reports with DAkkS certification to accelerate product release.

Quality Control Solutions

1. Smart Factory Integration

Data Kanban: Real-time display of key indicators such as yield rate and test pass rate of each production line.

Automatic sorting: test results are directly linked to the production system, and over-performing products are automatically labeled.

Process optimization: locate the process parameters that lead to strength fluctuations by comparing historical data.

2. Compliance Assurance

Standards coverage: Built-in ASTM D638/EN ISO 6892/GB/T 228 and other 30+ international standards.

Audit Trail: All operation records are traceable and meet ISO/IEC 17025 certification requirements.

Electronic Signature: Supports multi-level authority management, key reports need to be electronically signed by authorized personnel.

Send Inquiry to This Supplier

You May Also Like

-

ASTM D635 Vertical Combustion Tester With Data Logging FunctionUS$ 2000 - 3000MOQ: 1 Set

-

IEC 60695 Vertical Combustion Tester for Electrical ComponentsUS$ 2000 - 3000MOQ: 1 Set

-

UL 94 V-0 Vertical Combustion Tester for Flame Retardant MaterialsUS$ 2000 - 3000MOQ: 1 Set

-

ISO 1210 Vertical Combustion Tester for Textile Flame ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

EN 60335 Vertical Combustion Tester for Household Appliance SafetyUS$ 2000 - 3000MOQ: 1 Set

-

UL 1581 Vertical Combustion Tester for Wire & Cable InsulationUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Automotive Interior Materials TestingUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Furniture Upholstery Flame ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Children's Toy Safety ComplianceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester 100mm×100mm Sample Size for IEC 60695US$ 2000 - 3000MOQ: 1 Set