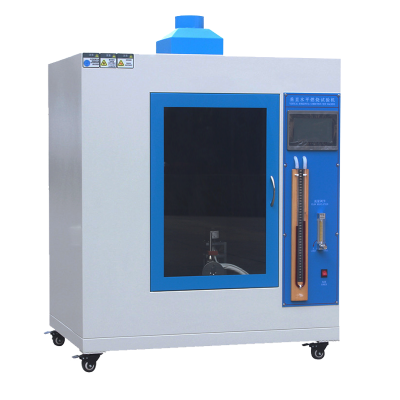

IEC 60695 Vertical Combustion Tester for Electrical Components

STANDARD FEATURES

Burning Chamber Capacity | ≥0.75m³ with glass observation door |

Burning Angle | 20 。, 45 。, 90 。 (ie 0 。) adjustable |

Flame Time | 0 ~ 99 minutes 99 seconds can be set |

After Flame Time | 0 ~ 99 minutes 99 seconds can be set |

After Glow Time | 0 ~ 99 minutes 99 seconds can be set |

Burner Dimensions | The inner diameter of the nozzle is Ø9.5±0.3mm, the effective length of the nozzle is 100±10mm, and there is an air adjustment hole |

Combustion Gas | LPG gas (Customize) |

Flame Height | Adjustable from 20mm to 175mm as standard |

Features | It is also equipped with lighting device, air extraction device, gas flow regulating valve, gas pressure gauge, gas pressure regulating valve, gas flow meter, gas U-shaped pressure gauge and sample fixture |

Power | AC 220v 50HZ |

IEC 60695 Vertical Flame Tester: A Professional Evaluation Tool for Flame Retardancy of Electrical Assemblies

Product Description

Ensuring the flame retardancy of materials is critical in the manufacture of electrical and electronic products, and the IEC 60695 Vertical Flame Tester is a sophisticated piece of equipment designed to meet this need. It is capable of simulating fire conditions likely to be encountered in actual use, and performs rigorous combustion performance tests on electrical components and materials.

Test Standards

The IEC 60695 series of standards covers a wide range of test methods to evaluate the performance of electrical assemblies under different fire hazard scenarios. The main test methods include:

Scorch wire test: assesses the fire resistance of non-metallic materials under overheating or short-circuit conditions.

Needle flame test: to determine the flame resistance of small components when exposed to small flames.

50W/500W flammability test: to evaluate the burning characteristics of materials under different power sources of ignition.

Test Methods

Scorch Wire Test: A scorch wire with a settable temperature is used to contact the material to observe whether ignition occurs and the duration of combustion.

Needle Flame Test: A needle flame is used to contact the test specimen to record the burning time and flame spread.

50W/500W Flammability Test: A flame of specified power is used to ignite the sample, burning time and flame spread are recorded, and the sample is graded according to burning duration and dripping.

Application Areas

Consumer electronics: Evaluate the fire resistance of plastic casings and PCB components of cell phones, laptops and other devices.

Household appliances: Test the flame retardancy of housing materials for electric appliances such as rice cookers and electric kettles.

Power tools: Ensure that hand-held power tool housings and internal components comply with fire protection standards.

Power equipment: for switchgear, transformers and other products of the flame resistance test.

Product Advantages

High precision: adopting advanced sensors and control system to ensure the accuracy and repeatability of test results.

High degree of automation: automatic ignition, timing, recording data and other functions reduce human error and improve testing efficiency.

Safe and reliable: with perfect safety protection mechanism, such as leakage protection, fire window protection, etc., to ensure the safety of operators and equipment.

Easy to operate: Intuitive touch screen interface and friendly operation prompts enable users to get started quickly.

Conclusion

The IEC 60695 Vertical Combustion Tester is ideal for ensuring the combustion safety of electrical components. It provides accurate data to support R&D and quality control by simulating real combustion conditions. By choosing our products, you are choosing precise control of the combustion properties of materials and strict quality control of products.

IEC 60695 Vertical Burning Tester requirements for flame retardancy of materials are mainly reflected in the following aspects:

1. Glow-Wire Test (GWT)

Scope of application: Evaluation of the fire resistance of non-metallic materials (e.g. plastic enclosures, insulating materials) under overheating or short-circuit conditions.

Test standard: IEC 60695-2-10 ~ IEC 60695-2-13.

Test Methods: A burning wire at a temperature of 550°C, 650°C, 750°C, 850°C or 960°C is used to contact the material for 30 seconds. Observe whether the material ignites and how long it burns, assessing whether the flame spreads and whether the dripping material ignites the lined sheet of cotton paper.

Evaluation Criteria: The material should not ignite or self-extinguish within 30 seconds after the removal of the hot wire and the drips should not ignite the lint.

2. Needle-Flame Test (NFT)

Scope of application: Evaluate the flame resistance of small parts of electronic products (e.g. PCBs, cables, electrical connectors) when exposed to small flames.

Test standard: IEC 60695-11-5.

Test Method: Use a 12mm high needle flame (temperature about 850°C) to contact the test sample for 5 seconds to 60 seconds. The burning time and flame spread are observed to assess whether the sample is self-extinguishing and whether the burning droplets ignite the thin cotton paper on which it is laid.

Evaluation Criteria: The sample should be self-extinguishing within 30 seconds after removal of the flame and the drippings should not ignite the cotton paper.

3. 50W/500W flammability test

Scope of application: To evaluate the burning characteristics of materials under different power sources of ignition.

Test standard: IEC 60695-11-10 ~ IEC 60695-11-20.

Test Methods: The sample is ignited by a 50W or 500W flame and the burning time and flame propagation are recorded. The material is graded according to the burning duration and burning drops (e.g. V-0, V-1, V-2).

Evaluation Criteria:

V-0: Flame self-extinguishes within 10 seconds and no molten droplets ignite the cotton pad.

V-1: Flame self-extinguishes within 30 seconds, allowing melt droplets but not igniting the cotton pad.

V-2: Flame self-extinguishes within 30 seconds, but melt droplets can ignite the liner.

These test methods and standards together constitute the IEC 60695 Vertical Flame Tester's comprehensive assessment of the flame retardancy of materials to ensure the safety and reliability of materials in practical applications.

Send Inquiry to This Supplier

You May Also Like

-

Vertical Combustion Tester for Furniture Upholstery Flame ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Children's Toy Safety ComplianceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester 100mm×100mm Sample Size for IEC 60695US$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester CE Marked for EU Market ComplianceUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Silicone Rubber FlammabilityUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester With PLC Control SystemUS$ 2000 - 3000MOQ: 1 Set

-

CE ISO 17025 Certified Image Measuring Instrument for Precision MetrologyUS$ 3000 - 5000MOQ: 1 Set

-

Image Measuring Instrument for PCB Circuit Board InspectionUS$ 3000 - 5000MOQ: 1 Set

-

Image Measuring Instrument for Automotive Component Dimensional ControlUS$ 3000 - 5000MOQ: 1 Set

-

Image Measuring Instrument for Aerospace Composite Material AnalysisUS$ 3000 - 5000MOQ: 1 Set