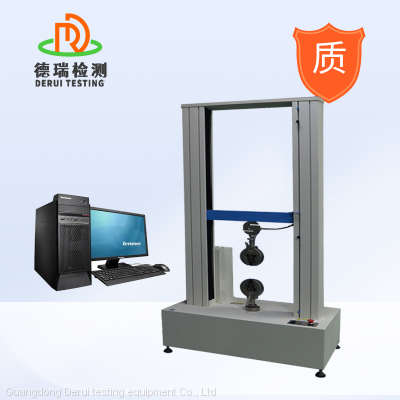

Computerized Tensile Strength Test Machine - Automated Testing With Data Analysis Software

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) | |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection | |

| Upper and lower limit switches | |

| Load sensor with automatic retreat |

Computerized Tensile Strength Tester - Automated Testing and Data Analysis Software

In the era of Industry 4.0, material testing is transforming from manual operation to intelligence and digitalization. Our computerized tensile strength testers are equipped with advanced automated testing systems and intelligent data analysis software, which realize the whole process of automation from sample loading to report generation, and provide enterprises with efficient and accurate material performance evaluation solutions.

I. Full-process automated testing system

Intelligent sample identification

Scanning gun automatically reads the QR code of the sample and matches the preset test parameters (material type, standard requirements, etc.)

Optical positioning system automatically calibrates the sample clamping position with an error of ≤0.05mm.

Support for continuous testing of multi-size samples (maximum capacity of 50 / batch)

Closed-loop servo control

Dynamic adjustment of loading speed (0.001-500mm/min), support for constant stress / constant strain control mode

Force / displacement dual closed-loop control to ensure test stability (speed control accuracy ± 0.2%)

Support sine wave / square wave / random wave and other complex loading waveforms (frequency range 0.01-10Hz)

Unattended testing

Automatic judgment of fracture and shutdown, automatic recording of fracture location and damage patterns

Supports unmanned test queue at night, preset 10 groups of test program cycle execution

Safety protection (overload protection, emergency braking) is automatically triggered in abnormal situations.

Intelligent data analysis software

1. Real-time analysis function

Automatic calculation of yield strength, tensile strength, elongation and other 12 core indicators

Real-time drawing stress - strain curve (support multiple curve comparison and local zoom)

Automatic labeling of key points (upper yield point, lower yield point, fracture point)

2. Advanced analysis module

Fatigue life prediction: Based on Miner's linear cumulative damage theory, predict the fatigue life of materials.

Crack Expansion Analysis: Calculate the crack expansion rate by Digital Image Correlation (DIC).

Data Anomaly Detection: Automatically identifies anomalous data points and flags suspicious test results using the 3σ method.

3. Reporting and Traceability

Automatic generation of ASTM/EN/ISO-compliant test reports, with support for customized templates

Encrypted test data storage (local + cloud backup), traceable to the original sensor signal

Support PDF/Excel/XML format export, compatible with LIMS system data interface.

Technical Parameters

Parameter Indicator

Maximum test force 300kN (optional 500kN/1000kN)

Force accuracy ±0.5%FS

Displacement resolution 0.001mm

Data acquisition frequency 1000Hz (high speed mode)

Compatible standards ASTM E8/EN 10002/ISO 6892 and other 50+ standards

Ambient temperature range 10-40℃ (optional - 20-60℃)

Industry Solutions

1. Automobile manufacturing

Application scenarios: engine connecting rod fatigue testing, tire cord strength verification, airbag fabric tear analysis

Value enhancement: 50% reduction of manual intervention through automated testing, fatigue life prediction model reduces testing costs by 30%.

2. Aerospace

Application scenarios: composite material interlaminar shear testing, titanium alloy fracture toughness analysis, seal creep performance testing

Technical advantages: high-speed data acquisition (1000Hz) to accurately capture the dynamic response of the material, DIC technology to achieve full-field strain analysis.

3. Building materials

Application scenarios: rapid reinforcement strength testing, concrete shrinkage stress analysis, tensile performance assessment of insulation materials

Efficiency Improvement: Supporting continuous testing of multiple samples, increasing the efficiency of single batch testing by 4 times.

4. Research Institutes

Application scenarios: R&D and testing of new materials, research on failure mechanisms, validation of standard methods.

Functional support: customized loading waveforms and complex testing procedures, helping cutting-edge research in materials science.

V. Smart Factory Integration

MES system docking

Test data is automatically uploaded to the production management system to realize batch traceability.

Test results are linked to the ERP system, automatically triggering quality judgment and production adjustment.

Remote Operation and Maintenance

Real-time monitoring of equipment status (temperature/humidity/running hours)

Fault warning and remote diagnosis, engineers can access system logs remotely.

Automatic software upgrades to keep functions and standards synchronized and updated

Send Inquiry to This Supplier

You May Also Like

-

CE Certified Tensile Strength Test Machine - Meet European Safety StandardsUS$ 3999 - 9999MOQ: 1 Set

-

CE UL Listed Vertical Combustion Tester for Plastics & ElectronicsUS$ 2000 - 3000MOQ: 1 Set

-

ASTM D635 Vertical Combustion Tester With Data Logging FunctionUS$ 2000 - 3000MOQ: 1 Set

-

IEC 60695 Vertical Combustion Tester for Electrical ComponentsUS$ 2000 - 3000MOQ: 1 Set

-

UL 94 V-0 Vertical Combustion Tester for Flame Retardant MaterialsUS$ 2000 - 3000MOQ: 1 Set

-

ISO 1210 Vertical Combustion Tester for Textile Flame ResistanceUS$ 2000 - 3000MOQ: 1 Set

-

EN 60335 Vertical Combustion Tester for Household Appliance SafetyUS$ 2000 - 3000MOQ: 1 Set

-

UL 1581 Vertical Combustion Tester for Wire & Cable InsulationUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Automotive Interior Materials TestingUS$ 2000 - 3000MOQ: 1 Set

-

Vertical Combustion Tester for Furniture Upholstery Flame ResistanceUS$ 2000 - 3000MOQ: 1 Set