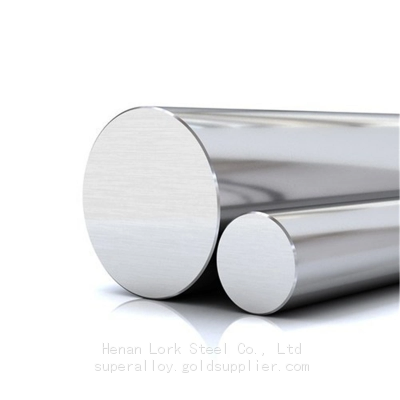

Lork Ns3403 N06985 2.4619 Hastelloy G3 Bar for Manufacture of Process Equipment

Introduction

Super alloys or high performance alloys have the ability to function at temperatures above 540ºC (1000ºF) with deformation resistance and high surface stability. As they have good oxidation and creep resistance, super alloys can be commonly forged, rolled to sheet or produced in various shapes. Iron-base, nickel-base and cobalt-base alloys are the major types of super alloys. Nickel-base and cobalt-base super alloys may be cast or wrought based on its composition or application. The iron-base super alloys are generally wrought alloys with stainless steel technology. These alloys can be strengthened by precipitation hardening, work hardening and solid-solution hardening.

HASTELLOY(r) G-3 alloy has high tungsten and molybdenum contents, which makes it resistant to corrosion.

The following section will discuss in detail about HASTELLOY(r) G-3 alloy.

Chemical CompositionThe following table shows the chemical composition of HASTELLOY(r) G-3 alloy.

| Element | Content (%) |

|---|---|

| Chromium, Cr | 21-23.5 |

| Iron, Fe | 18-21 |

| Molybdenum, Mo | 6-8 |

| Cobalt, Co | 5 max |

| Copper, Cu | 1.5-2.5 |

| Tungsten, W | 1.5 max |

| Silicon, Si | 1 max |

| Manganese, Mn | 1 max |

| Niobium+Tantalum (Ni+Ta) | 0.5 max |

| Phosphorus, P | 0.04 max |

| Sulfur, S | 0.03 max |

| Carbon, C | 0.015 max |

| Nickel, Ni | Remainder |

The physical properties of HASTELLOY(r) G-3 alloy are given in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.3 g/cm³ | 0.3 lb/in³ |

| Melting point | 1343ºC | 2450ºF |

Other Designations:

The Advanced Materials Show - Highlights from 2022 eBook

Equivalent materials to HASTELLOY(r) G-3 alloy are the following:

ASTM B582

ASTM B619

ASTM B622

ASTM B626

DIN 2.4619

Fabrication and Heat TreatmentMachinability

HASTELLOY(r) G-3 alloy can be machined using conventional techniques employed for iron based alloys. The quality of the alloy can be improved with the utilization of water-base coolants. Heavy duty machining tools and equipment can be used prior to cutting in order to reduce chattering or work-hardening of the alloy.

FormingHASTELLOY(r) G-3 alloy can be formed through conventional forming methods.

WeldingWelding of HASTELLOY(r) G-3 alloy is performed through commonly used welding techniques like gas tungsten arc welding, shielded metal-arc welding, metal-arc welding and submerged-arc welding. However, an alloy filler metal that suits this alloy should be used.

Cold workingHASTELLOY(r) G-3 alloy can be cold worked using standard tooling methods. As plain carbon steels produce galling, they are not preferred for forming HASTELLOY(r) G-3 alloy. Galling can be minimized with the help of heavy duty lubricants.

AnnealingAnnealing of HASTELLOY(r) G-3 alloy can be performed at 1177ºC (2150ºF) followed by rapid cooling of air and water quenching.

HardeningHASTELLOY(r) G-3 alloy can be hardened by cold working.

ApplicationsHASTELLOY(r) G-3 alloy finds its application in the manufacture of process equipment for mixed acids, sulfate compounds and flue gas scrubbers.

Send Inquiry to This Supplier

You May Also Like

-

Lork Uns N10675 Hastelloy B3 Nickel Sheet/Nickel Strip/Nickel Plate in StockUS$ 40 - 50MOQ: 100 Kilograms

-

Lork Black Finish Monel 400 Nickel Alloy Round Bar for FramesUS$ 20 - 30MOQ: 100 Kilograms

-

Lork High Hardness DIN 2.4375 Monel K500 Nickel Based Alloy Plate for Sea Water Pump ShaftsUS$ 30 - 40MOQ: 100 Kilograms

-

Lork Wholesale Spot Brushed Round Monel R405 Nickel Based Allooy Bar for FastenersUS$ 20 - 30MOQ: 100 Kilograms

-

Lork Hot Selling Ni-Cu Alloy Monel 404 Nickel Plate for Chemistry and Petrochemical YieldUS$ 30 - 40MOQ: 100 Kilograms

-

Lork Good Creep Oxidation Resistance Monel 502 Nickel Alloy Bar for Propeller ShaftsUS$ 20 - 30MOQ: 100 Kilograms

-

Lork Brushed Finish Incoloy A-286 Nickel Round Bar With Spot WholesaleUS$ 30 - 40MOQ: 100 Kilograms

-

Lork ASTM DIN Standard Nickel Alloy Incoloy 800 Plate for Resistance to Stress CrackingUS$ 30 - 40MOQ: 100 Kilograms

-

Lork Super Alloy Nimonic 90 (UNS N07090) Bright Surface Nickel Alloy 90 SheetUS$ 30 - 40MOQ: 100 Kilograms

-

Lork AMS 5510 AMS 5645 Tisco Baosteel 321 / 321H Stainless Steel Plate For Laboratory Equipment ManufacturingUS$ 500 - 1800MOQ: 1 Ton