Introduction to Reel Cable

Reel cable is a specially designed cable mainly used for power transmission on reel equipment. It is usually applied to large and medium-sized construction machinery equipment such as lifting equipment, cranes, ship loaders, stackers, and large and medium-sized shore bridges. Reel cables are required to have characteristics such as cold resistance, wear resistance, corrosion resistance, softness, and oil resistance, as well as strong mechanical load bearing capacity. In addition, the drum cable should also have good bending performance to meet the working requirements of the drum equipment.

Application scenarios of reel cables

The key application scenario of reel cables is under harsh working conditions, such as humid seaside conditions. According to the specific application environment, the selection of drum cables needs to consider factors such as cable shape, voltage, and specifications. For example, when the cable is flat, it is important to determine the width of the cable; When the cable is circular, it is necessary to focus on determining the overall outer diameter of the cable. In addition, drum cables also need to adapt to special environments such as high temperature and chemical corrosion.

The characteristics of drum cables

The characteristics of drum cables include:

Cold and wear-resistant: able to withstand harsh working environments and maintain flexibility even at low temperatures.

Heat resistant and flame retardant: able to work normally at high temperatures, while also possessing flame retardant properties.

Anti extrusion: In the operation of the drum, the cable needs to withstand long-term bending motion, and has excellent tensile properties, pressure resistance, especially rolling resistance and wear resistance.

Waterproof and UV resistant: suitable for outdoor mobile devices, with waterproof and UV resistant aging capabilities.

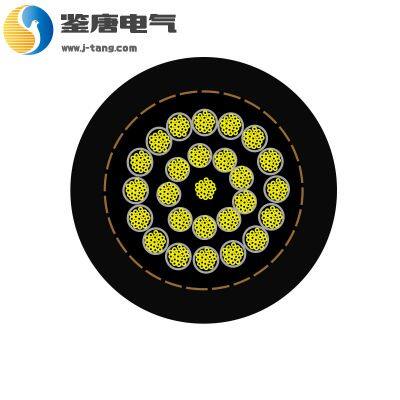

Structure of Reel Cable

The structure of drum cables typically includes multiple strands of fine twisted tinned copper wire conductors, natural or synthetic rubber insulation, core wires twisted into cables at small intervals, and chloroprene rubber outer sheaths. These structural designs ensure the mechanical performance and durability of the cable during use.

Precautions for selecting drum cables

When selecting reel cables, the following points should be noted:

Cable cross-section: When the cable cross-section is 35mm ² Non electric drums should not be chosen.

Cable arrangement: Drum cables are divided into two types based on cable arrangement: axial single row and axial multi row.

Location of collector slip ring: According to the location of collector slip ring, it can be divided into two forms: internal sliding ring type and external sliding ring type.

Winding materials: According to the winding materials, they are divided into cable reels and hose reels.

Send Inquiry to This Supplier

You May Also Like

-

Special Cable for Underwater CameraNegotiableMOQ: 5000 Meters

-

Zero Buoyancy CableNegotiableMOQ: 5000 Meters

-

Polyether Anti-corrosion and Seawater Resistant CableNegotiableMOQ: 5000 Meters

-

High Voltage Silicone Flat CableNegotiableMOQ: 1000 Meters

-

Specializing in the Production of Specialized Cables for Harvesters.NegotiableMOQ: 1000 Meters

-

Liquid Level Sensor CableNegotiableMOQ: 10000 Meters

-

Flexible Control Combination CableNegotiableMOQ: 1000 Meters

-

Optoelectronic Composite CableNegotiableMOQ: 1000 Meters

-

Sheathed Composite CableNegotiableMOQ: 1000 Meters

-

The Difference Between Different Types of Automotive Cables and Selection AdviceNegotiableMOQ: 500 Meters