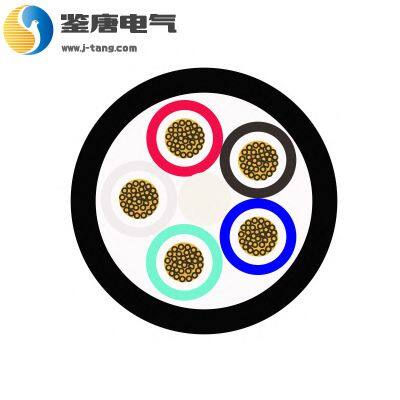

Overview of sheathed composite cables

Sheath composite cable is a special type of cable that uses multiple materials and technologies to meet specific usage needs. This type of cable typically includes an external sheath, which provides additional protection to prevent mechanical damage to the cable during installation and use. In addition, sheathed composite cables may also have characteristics such as flame retardancy, fire resistance, and high temperature resistance, allowing them to maintain good performance in harsh environments.

Material selection of sheathed composite cables

The material selection of cable sheath is very important because it directly affects the performance and service life of the cable. Common sheath materials include PVC (polyvinyl chloride) and PE (polyethylene). PVC has the characteristics of low cost, good flexibility, and appropriate consolidation, but at the same time, it also has environmental protection issues. In contrast, PE has excellent electrical insulation performance and outstanding processing functions, and is more environmentally friendly.

Application scenarios of sheathed composite cables

Sheath composite cables are suitable for power systems under various harsh environmental conditions, such as high temperature, humidity, chemical corrosion, and other places. They not only effectively protect cable systems, but also reduce environmental pollution, meeting the requirements of sustainable development.

Technological innovation of sheathed composite cables

With the advancement of technology, the technological innovation of cable sheaths is also constantly developing. The development of new high-temperature refractory materials provides a broader development space for cable fireproof sheaths, while the application of intelligent monitoring and remote management technology improves the safety and reliability of cable systems. In the future, cable fireproof sheaths will also be integrated with intelligent building systems to achieve interconnection and interoperability with them, providing more comprehensive protection for building safety.

Key points for selecting sheathed composite cables

When selecting sheathed composite cables, the following points need to be considered:

Usage environment: Understand the environment in which the cable will work, in order to select cables with corresponding characteristics.

Conductor material: Copper core cables have good conductivity and mechanical strength.

Insulation materials: Select materials with appropriate temperature resistance and insulation performance.

Sheath material: Select appropriate sheath material based on environmental adaptability and compatibility.

Certification standards: Ensure that cables comply with relevant national mandatory product certifications and international standards.

Send Inquiry to This Supplier

You May Also Like

-

Mooring Rope CableNegotiableMOQ: 1000 Meters

-

Special Cable for Underwater CameraNegotiableMOQ: 5000 Meters

-

Zero Buoyancy CableNegotiableMOQ: 5000 Meters

-

Polyether Anti-corrosion and Seawater Resistant CableNegotiableMOQ: 5000 Meters

-

High Voltage Silicone Flat CableNegotiableMOQ: 1000 Meters

-

Specializing in the Production of Specialized Cables for Harvesters.NegotiableMOQ: 1000 Meters

-

Liquid Level Sensor CableNegotiableMOQ: 10000 Meters

-

Flexible Control Combination CableNegotiableMOQ: 1000 Meters

-

Optoelectronic Composite CableNegotiableMOQ: 1000 Meters

-

The Difference Between Different Types of Automotive Cables and Selection AdviceNegotiableMOQ: 500 Meters