Biomass Wood Chips Palm Kernel Shell Fired Steam Boiler For Palm Oil Processing Plant

Biomass Wood Chips Palm Kernel Shell Fired Steam Boiler for palm oil processing plant

1. Steam Boiler capacity:1-4ton/h

2. Stem pressure: 0.7MPa (7bar) ,1.0MPa(10bar),1.25MPa(13bar), 1.6MPa(16bar)

3. Steam temperature output: 170℃, 184℃, 193℃, 204℃

4. Available fuel: biomass, wood pellet,peanut, paddy, rice husk,sawdust solid fuel.

5. Boiler Structure: Horizontal three pass fire tube industrial used steam boiler

6. Application:used for all kinds of industrial production and processing.

7. Standard of Design, Manufacturing and Inspection: GB150

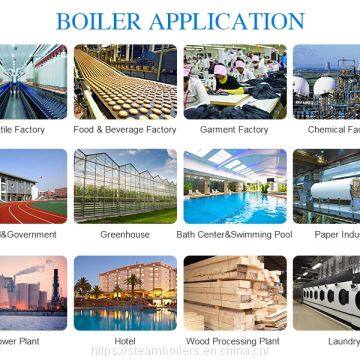

Application:Textile Mill,Food and Beverage,Chemical,Medicine,Light Industry,Rubber,Printing and Dyeing Plant,Paper Mill,Wood Processing,Garment and Laundry etc.

Boiler Description

DZH series coal/biomass fired steam boiler realizes almost zero pollution with the use of special dust collector solution. This series boiler is single drum horizontal type shell boiler, the combustion equipment is moving grate. The fuel could be II class bituminous coal and biomass fuel, the diameter of coal should be 6-25mm, and ash content should be less than 32.4%, and for the biomass fuel, carbon content should less than 50%, sulphur content less than 0.08%, and ash content less than 3%.

Boiler specification sheet

Boiler Model | DZH1-1.25 | DZH2-1.25 | DZH4-1.25 |

Steam output (t/h) | 1.0 | 2.0 | 2.0 |

working pressure (Mpa) | 1.25 | 1.25 | 1.6 |

steam temperature (℃) | 193 | 193 | 204 |

Feed water temperature (℃) | 20 | 20 | 20 |

heat exchange area (㎡) | 25.7 | 8.409 | 8.44 |

Available fuel | BMF | ||

design thermal efficiency | 78.59 % | 74.88% | 79% |

exhaust smoke temperature (℃) | 151.9 | 168.7 | 151.4 |

Transport size (L*W*H) | 5.1 x 2.25 x 3.05m | 5.05 x 2.5 x 3.2m | 5.5 x 2.8 x 3.4 m |

Classical Structure

Advanced Structure: DZH boiler adopting threaded fire tubes, single water drum, horizontal shell type boiler with 3 fire-passes structure, water-tube fire-tube mix design. Comparing with DZL series boiler, DZH series boiler has better adaptability on fuels, it can fire coal, rice husk, nut shell, sawdust, waste wood pieces, also can fire wood logs, straws. But, coal fired steam boiler can only support manual fuel feeding, and manual ash remove.

High Quality Control

High Quality Control: In manufacturing processes, we has adopting steel strength test, automatic steel cutting/ plate rolling/ welding, 100% x-ray welding check, magnetic particle check c-scan ultrasonography Ultrasound check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency test,etc, to make sure all finished products is qualified.

Low Fuel & Labor Cost

Biomass steam boiler can firecoal, rice husk, nut shell, sawdust, waste wood pieces, also can fire wood logs, straws. This will markedly reduce user’s fuel consumption cost, increase company’s benefits. Only need 1 worker to operate the fuel feeding and slag removing.

Application for biomass steam boiler

Coal fired steam boiler is widely used in hospitals, schools, textile mills, garment factories, large supermarket, garment factories, dyeing factory, hotel, dining room, restaurant, food factory, beverage factory, soy products, meat products factory, cannery, brewery, pharmaceutical factory, packaging plant, building materials factory, paint factory, swimming pool and other places of the enterprises and institutions.

Boiler picture

Send Inquiry to This Supplier

You May Also Like

-

Horizontal Structure Wood Chips Steam Boiler For HotelUS$ 13500 - 15000MOQ: 1 Set

-

6000kg 6ton Bagasse Fired Steam Boiler Biomass Steam Boiler for Surgar FactoryUS$ 45000 - 49000MOQ: 1 Set

-

High Efficiency 4tons/hr Wood Steam Boiler for Plywood Hot Press MachineUS$ 45000 - 49000MOQ: 1 Set

-

300hp 4ton 4000kg/hr Waste Wood Fired Steam Boiler for MDF Production PlantUS$ 35000 - 39000MOQ: 1 Set

-

Professional Manufacturer Supply Coal Wood Biomass Pellet Fired Steam Boiler for HotelUS$ 35000 - 39000MOQ: 1 Set

-

High Performance Biomass Wood Chip Fired Steam Boiler for EPS IndustryUS$ 35000 - 39000MOQ: 1 Set

-

4 Ton Waste Fabric Biomass Wood Chips Fired Steam Boiler For Textile FactoryUS$ 13500 - 19000MOQ: 1 Set

-

1ton 2ton 3ton 4ton Industrial Energy Saving Wood Chips Coal Fired Steam Boiler for Rice Mill PlantUS$ 13500 - 19000MOQ: 1 Set

-

1500kg 1.5ton 100hp Wood Dust/Chips Biomass Pellet Fired Industrial Steam Boiler For GreenhouseUS$ 13500 - 15000MOQ: 1 Set

-

Industrial Coal/Biomass Pellet Fired Steam Boiler For Tomato Paste Processing MachineUS$ 13500 - 15000MOQ: 1 Set