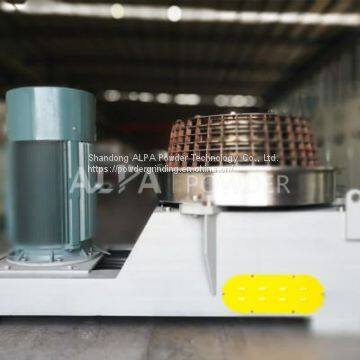

Vortex Mill Coating Production Line Powder Grinding and Coating System

Vortex Mill Coating Production Line Powder Grinding and Coating System

Widely used in the coating of various materials in the non-metallic mineral industry. Contains: quartz, powder quartz, fused silica, cristobalite, quartzite, vein quartz, quartz sand, feldspar (sodium, potassium), sepiolite, andesite plagioclase, nepheline syenite, garnet, oblique Feldspar, illite, kaolin (calcined kaolin, coal kaolin, washed kaolin), light calcium carbonate, heavy calcium carbonate (calcite, limestone, marble, chalk), talc (white, black), barite, mica (natural, synthetic), bentonite, andalusite, brucite, montmorillonite, graphite, diatomaceous earth, bauxite, petroleum coke, coal powder, magnesite, perlite, attapulgite, spinel, Tourmaline, medical stone, monazite, pyrophyllite, dolomite, rectorite, diopside, translucent stone, porphyrite, cordierite, vermiculite, mullite, clay, clay and other minerals.

Vortex Mill Powder Surface Modification Technical Parameters

| Model | RTM-300 | RTM-400 | RTM-500 | RTM-750 | RTM-1000 |

| Particle Size | D97:10um | D97:10um | D97:10um | D97:10um | D97:10um |

| Production Capacity | 500Kg/h | 900Kg/h | 1500Kg/h | 2000-2500Kg/h | 4000Kg/h |

| Power | 22kw | 37kw | 45kw | 75kw | 110kw |

(abbreviation: ALPA / Equity Code: 171033)

ULTRA-FINE POWDER SOLUTIONS

In the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.

Q: What service do you supply?

2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supply project engineering, automation engineering and civil engineering.

4). We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:How can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. And we can provide free training for on-site workers.

Q:How to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

Send Inquiry to This Supplier

You May Also Like

-

Lithium Cobalt Oxide Powder Disc Jet Mills Air Jet Mill Micronizer for SaleUS$ 9999 - 90000MOQ: 1 Set

-

Lithium Manganese Oxide Powder Grinding Machine Spiral Jet MillUS$ 9999 - 90000MOQ: 1 Set

-

White Carbon Black Ultrafine Grinding High Purity Steam Air Jet MillUS$ 9999 - 90000MOQ: 1 Set

-

Silver Powder Grinding Mills Spiral Flow Jet Mill SystemsUS$ 9999 - 90000MOQ: 1 Set

-

Calcite Powder Grinding Machine ACM Air Classifying MillUS$ 9999 - 90000MOQ: 1 Set

-

Sulfur Powder ACM Grinding Machine Air Classifier Mill MachineryUS$ 9999 - 90000MOQ: 1 Set

-

Lithium Hydroxide Powder Grinding Machine Jet MillUS$ 9999 - 90000MOQ: 1 Set

-

Jet Mill for SaleUS$ 9999 - 90000MOQ: 1 Set

-

Grinding Mill / Milling MachineUS$ 9999 - 90000MOQ: 1 Set

-

Grinding Mill Pin Mill MachineUS$ 9999 - 90000MOQ: 1 Set