Sack Gabions

Products: Sack Gabions

Sack Gabions Description:

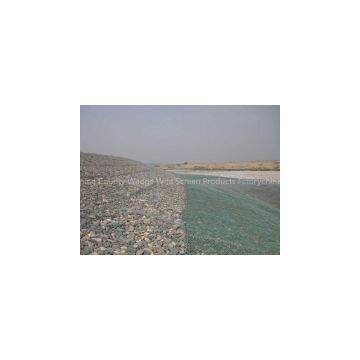

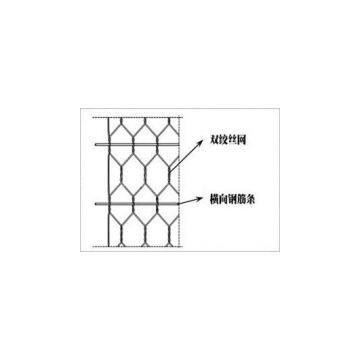

Sack Gabions consist of a single mesh panel made of hexagonal woven wire Mesh Type 80, commonly referred as double twisted wire mesh (Figure 1 and Table 1). Sack Gabions are filled with rocks at the project site to form a flexible, permeable and monolithic structure. This structure is used for emergency and river training in works when local conditions require fast installation, or when the water does not allow easy access to the site or when underwater installation is necessary.

The material used in the manufacture of Sack Gabions is heavily zinc coated steel wire. If necessary, a PVC coating is extruded over the galvanized wire to provide additional protection in aggressive environments. The PVC coating has a nominal thickness of 0,5 mm. The tolerances of mesh and wire are shown in Table 1 and Table 2. The end of the mesh has steel rods inserted during the manufacturing process to drive closing during installation. Dimensions and sizes of galvanized and PVC coated Sack Gabions are shown in Table 3. When specifying Sack Gabions in the tender documents or bill of quantities, please refer to Table 4.

Filling and Lacing

The Sack Gabion is assembled by rolling the mesh panel into a cylindrical shape and lacing the overlapped edges (Figure 4). Once one end of the cylinder is tied and laced closely, the Sack Gabion is filled with rocks ranging between 100 mm and 200 mm or any other material of suitable size. The range in sizes maybe from 80mm. 5% oversize or 5% undersize is also allowable, provided it is not placed at the exposed surface. In all cases, oversize rock should not be larger than 300 mm and the undersize rock should not be smaller than 100 mm. Rocks should be hard, angular, round and durable. So they shall not disintegrate on expose to water or weathering during the life of the structure. Care should be taken when placing the stone to ensure that the PVC coating on the Sack Gabion is not damaged. To expedite installation, two or more Sack Gabion can be tied together before installation. About lacing wire, lacing operation can be made by using certain tools available from our offices together with stainless steel rings.

Please refer to the following specifications:

Diameter: 3mm Tensile strength: 156-178 kg/mm2

Spacing of the rings or loops must not exceed that shown in Figure 5B.

Send Inquiry to This Supplier

You May Also Like

-

Black Iron Wire ClothUS$ 1.8 - 1.8MOQ: 30 Sets

-

Wedge Wire Johnson Screen Nozzles , Stainless Steel Filter Nozzle, Filter Bottom Strainer NozzleUS$ 5 - 26MOQ: 50 Pieces

-

Wedge Wire Filter Nozzle, Johnson Screen Nozzle, Stainless Steel Strainer Nozzle, Filter Bottom Nozzle ElementUS$ 5 - 25MOQ: 20 Pieces

-

Vibrating Sieve Screen, v Wire Screen PanelUS$ 80 - 260MOQ: 10 Pieces

-

Wedge Wire Johnson Screen Pipe , Vee-wire Wrapped Screen Tube for Well Drilling, Sand Control, Dewatering PumpUS$ 60 - 160MOQ: 30 Pieces

-

Rod Based Vee-Wire ScreensUS$ 30 - 195MOQ: 20 Sets

-

Wedge Wire Wrap Well Screen , Dewatering Well Screen Pipe, Sand Control Well Screen TubeUS$ 80 - 180MOQ: 15 Pieces

-

Low Carbon Galvanized Johnson Specialty Screen TubeUS$ 30 - 80MOQ: 15 Meters

-

Wire Wrapped Sprial Screen Pipe, Stainless Steel Strainer PipeUS$ 95 - 195MOQ: 10 Pieces

-

Woven Wedge Wire Water Well Screen Pipe, Wire Wrapped Johnson Filter Screen TubeUS$ 20 - 70MOQ: 20 Meters