High Efficiency CNC Gear Hobbing Machine

GHKX-320A GHKX-320MA GHKX-200A GHKX-200MA

Machine Summary

The model GHKX-320A, GHKX-200A, GHKX-320MA and GHKX-200MA developed by our factory are a 2/3 axes CNC gear hobbing machines. The CNC axes are: X-axis--radial feed motion; Z-axis--axial feed motion; Y-axis--hob shifting motion(hob shifting of GHKX-320A, GHKX-200A use AC motor drive). These machines are widely used to cut cylindrical spur and helical gears, crowning and slightly tapered gears. It is powerful and strong enough to work under heavy-duty or high-speed hobbing condition, and so it is an economic and high efficient gear hobbing machine suitable for gear manufacturing industries, such as automobile, tractor, etc. in mass production.

Performance and Feature

1. Being of vertical design, main bulky components like bed and column adopt the double-wall construction with large-sized reinforce-rib, rectangular, flat and ample guideways covered with Tefion, so the machine features compact construction, short transmission chain and high a accuracy. Axial(Z-axis) and radial(X-axis) feed axes are driven by AC servomotors through preloaded ball screws. The spindle driven by AC frequency-variable motor has speed stepless. All guideways are automatically lubricated.

2. The frequency-converter for spindle drive, CNC controller, and the key hydraulic components are all from the reputable manufactures.

3. The machine with high degree of automation can work in several square cycles; in addition, cutting parameter can also be changed automatically in each square cycle. Either climb or conventional method may be used. Meanwhile the machine can cut workpiece with using multi-start hob and higher feed rate.

4. CNC control system: FANUC system is used as standard SIEMENS system is altemative one. The machine with high degree to automation can work repeatedly under the square cycle. Changing radial feed rate, selection of climb or conventional hobbing, hob shifting functions are avaiable. The main components of control system are supplied by renowned companies.

Remarks

Standrad equipment: main machine, hob arbor assemblies Φ32 and Φ40 one for each, a complete set of change gears, tools for installation and adjustment.

Technical Parameters

| Specifications | Units | GHKX-320A GHKX-320MA | GHKX-200A GHKX-200MA |

| Max. workpiece dia. | mm | 320 | 200 |

| Max. module | mm | 8 | 6 |

| Min. No. of teeth machined | 6 | 6 | |

| Min. unit for programming | mm | 0.001 | 0.001 |

| Max. worktable speed | rpm | 32 | 32 |

| Hob speed | rpm | 120-540 | 120-540 |

| Axial feed speed | mm/r | 0.5-4 | 0.5-4 |

| Radial feed speed | mm/r | 1-4 | 1-4 |

| Center distance between hob and worktable | mm | 60-250 | 40-230 |

| Distance between hob axis and worktable surface | mm | 280-530 | 280-530 |

| Distance between wailstock end face and worktable surface | mm | 375-675 | 375-675 |

| Hob axial travel | mm | 145/150 | 145/150 |

| Max. hob head swiveling angle | deg. | ±45 | ±45 |

| Max. hob diameter*length | mm | 160*200 | 160*200 |

| Worktable dimension dia.*bore diameter | mm | 320*100 | 320*100 |

| Motor capacity/Main motor power | Kva/kw | 27/11 | 27/11 |

| Machine dimension(L*W*H) | cm | 333*272*313 | 333*272*313 |

| N.W/G.W | kg | 9000/10000 | 9000/10000 |

| No. of cases | 4 cases in total | 4 cases in total |

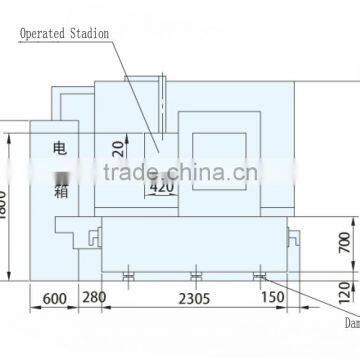

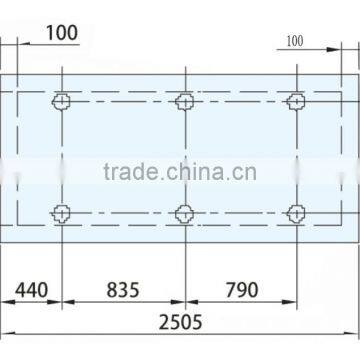

Foundation Plan

Send Inquiry to This Supplier

You May Also Like

-

Acrylic CNC Polishing Machines for Furniture IndustryNegotiableMOQ: 1 Set

-

Reliable Waterjet Cutting Machine for Stone Marble Porcleain Cutting IndustryUS$ 20000 - 40000MOQ: 1 Set

-

Custom Plastic Stainless Steel Aluminum CNC Machining PartNegotiableMOQ: 1

-

CNC Lathe Turned Machining Solid Shaft PinNegotiableMOQ: 1

-

Autopilot Flight Parts Manufacture and MIM Powder MetallurgyNegotiableMOQ: 1 Piece

-

Refrigerant gas R407NegotiableMOQ: 1 Piece

-

High Precision Machining Products of Stainless Steel Made in ChinaUS$ 1.5 - 1.5MOQ: 1000 Kilograms

-

Stainless Steel Welding Tee Pipe FittingsUS$ 0.9 - 0.9MOQ: 200 Pieces

-

OEM CNC Custom Machining Engineering Small Packaging Machine PartsUS$ 0.2 - 100MOQ: 1 Piece

-

Www.xtlaser.comHot Sale Dot Peen Pneumatic Marking MachineUS$ 1,400 - 1,600MOQ: 1 Set