Small-type CNC Gear Hobbing Machine(X and Z-axis)

GH-200CNC1 GH-200CNC2

Machine Summary

The model GH-200CNC1 gear hobbing machine is of one-axis CNC one, its control axis: X-axis--radial feed motion. It is designed for cutting cylindrical spur & helical gears and wormwheels with automatic feeding method, etc. The worktable of the machine adopts double-start worm gearing, so that it has high efficiency. It is suited for the industries that produce small-sized gears, such as motorcycle and mini-bus on batch production in automatic cycle working method as well as only single setup during cutting the workpiece.

The model GH-200CNC2 gear hobbing machine is of 2-axis CNC one, its control axes: X-axis--radial feed motion, Z-axis feed motion. It is designed for cutting cylindrical spur & helical gears, crowning & slightly tapered gears and wormwheels with radial feeding method, etc.

Performance and Feature

1. With vertical design, the worktable can move as radial feed movement.

2. Electrical system adopts GSK 980TD CNC system.

3. The modular valves available from Northman has high reliability and low failure rate in order to be convenient to diagnose failures and maintain hydraulic system.

4. The worktable is fitted with double-start worm as its index gearing. It is suitable for cutting the workpiece with No. of less-teeth.

5. The hob spindle adopts circulating lubrication to ensure sufficient and reliable lubrication for spindle bearing in order to prolong their service life. Meanwhile circulating oil can qucikly remove heat caused by spindle running to insure high rotary accuracy for the spindle.

Special Attachments

Hydraulic fixtures, Workpiece arbors, Live center, Shift hob head, Tangential hob head is available for GH-200CNC1, Hobbing head swivel angle right: 45°, left:30°.

Remarks

Standard attachments: main machine, one set of standard change gears, one set of special tool, hob arbors of Φ22 and Φ27 one for each.

Technical Parameters

| Specifications | Units | GH-200CNC1 | GH-200CNC2 |

| Max. workpiece dia. | mm | 200 | 200 |

| Max. module | mm | 4 | 4 |

| Max. worktable speed | r/min | 25 | 25 |

| Spindle speed/steps | r/min | 70-365/8 | 70-365/8 |

| Distance between hob axis and worktable surface | mm | 125-295 | 125-295 |

| Center distance between hob and worktable | mm | 20-170 | 20-170 |

Distance between end face of bearing bore of tailstock and worktable surface | mm | 240-438 | 240-438 |

| Hob shifting travel(manual) | mm | 50 | 50 |

| Max. hob head swivel angle | deg | ±45 | ±45 |

| Max. hob dia. and length | mm | 110*110 | 110*110 |

| Worktable dia.*bore dia. | mm | Φ180*Φ40 | Φ180*Φ140 |

| T-slot of worktable | 3*M12 | 3*M12 | |

| Total power/Main motor power | Kva/kw | 4.3/3 | 4.3/3 |

| Machine dimensions(L*W*H) | cm | 174*115*157 | 174*115*157 |

| No. of cases | 1 cases in total | 1 cases in total | |

| N.W/G.W | kg | 2000/2250 | 2000/2250 |

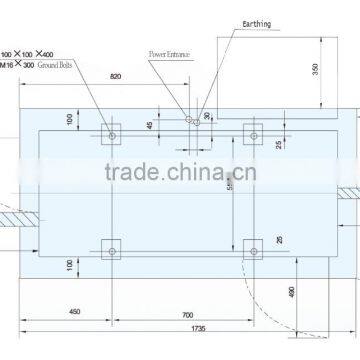

Foundation Plan

Send Inquiry to This Supplier

You May Also Like

-

Acrylic CNC Polishing Machines for Furniture IndustryNegotiableMOQ: 1 Set

-

Reliable Waterjet Cutting Machine for Stone Marble Porcleain Cutting IndustryUS$ 20000 - 40000MOQ: 1 Set

-

Custom Plastic Stainless Steel Aluminum CNC Machining PartNegotiableMOQ: 1

-

CNC Lathe Turned Machining Solid Shaft PinNegotiableMOQ: 1

-

Autopilot Flight Parts Manufacture and MIM Powder MetallurgyNegotiableMOQ: 1 Piece

-

Refrigerant gas R407NegotiableMOQ: 1 Piece

-

High Precision Machining Products of Stainless Steel Made in ChinaUS$ 1.5 - 1.5MOQ: 1000 Kilograms

-

Stainless Steel Welding Tee Pipe FittingsUS$ 0.9 - 0.9MOQ: 200 Pieces

-

OEM CNC Custom Machining Engineering Small Packaging Machine PartsUS$ 0.2 - 100MOQ: 1 Piece

-

Www.xtlaser.comHot Sale Dot Peen Pneumatic Marking MachineUS$ 1,400 - 1,600MOQ: 1 Set