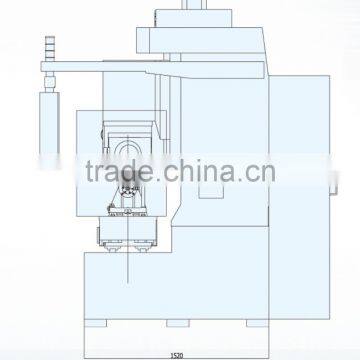

High Efficiency CNC Gear Shaving Machine

320-Type and 400-Type

Machine Summary

The series gear shaving machines are of heavy-duty gear finish-cutting machines. The series gear shaving machines are high rigid ones. They are suited for finish cutting external cylindrical spur & helical gears, and shaft gears. The CNC axes are: cutter rotary motion; cutter head swiveling motion; worktable axial feed motion and cutter head slide radial motion, as well as copying mechanism, etc. These machines feature good rigidity, stability, easy adjustment and operation, and high efficiency. It is quite suitable for industries, such as automobile, motorcycle, and etc.

Main Features

1. The series CNC gear shaving machines have respectively controlled CNC axes: Z-axis radial feed of the slide, X-axis axial feed of the worktable, A-axis cutter head swivel angle, B-axis cutter rotation, W-axis copying mechanism.

2. Either parallel or plunge shaving is available.

3. Capable of shaving crowning and tapered gears.

4. Cutter head automatic releasing, swiveling and locking.

5. Shaving speed changed steplessly; radial and axial feed rates setup steplessly; micro-back feed of cutter; rough/finish shaving change-over, dwelling cutting.

6. High rigidity bearings for supporting spindle and centers.

7. Guideways for worktable axial movement and copying mechanism rest are of linear ones.

8. Rapid cutter locking mechanism.

9. Independent hydraulic and cooling systems.

10. Metered lubrication system for guideways.

11. Equipped with automatic magnetic chip conveyer.

Technical Parameters

320-Type

| Specifications | Units | GS-320CNC1 GS-320CNC2 GS-320CNC3 GSK-320 GS-320CNC5 GSZ-320CNC5 | GSD-320CNC1 GSD-320CNC2 GSD-320CNC4 GSD-320CNC5 | GST-320CNC1 GST-320CNC2 GSKT-320T |

| Max. workpiece dia. | mm | 320 | 320 | 320 |

| Max module | Parallel-shaving:6 Plunge-shaving:4 | Parallel-shaving:8 Plunge-shaving:6 | Plunge-shaving:4 | |

| CNC servo axes | Z-axis Z,X-axis Z,X,A-axis Z,X,A,B-axis Z,X,A,B-axis Z,X,A,B-axis | Z-axis Z,X-axis Z,X,A,B-axis Z,X,A,B-axis | Z-axis Z,A-axis Z,A,B-axis | |

| Max. distance between two centers | mm | 700 | 700 | 700 |

| Cutter speed(stepless) | rpm | 50-400 | 50-400 | 50-400 |

| Radial feed speed(stepless) | mm/min | 0.2-500 | 0.2-500 | 0.2-500 |

| Worktable feed speed(stepless) | mm/min | 15-400(CNC1) 1-500(CNC2,3,4,5) | 15-400(CNC1) 1-500(CNC2,4,5) | |

Center distance between cutter axis and center | mm | 115-280 | 125-280 | 115-280 |

| Max. cutter diameter | mm | 240 | 240 | 240 |

| Cutter hole diameter | mm | 63.5 | 63.5 | 63.5 |

| Cutter width | mm | 20-50 | 20-50 | 20-50 |

| Cutter head swivel angle | deg | ±20 | ±20 | ±20 |

| Resolution of linear axis | mm | 0.001 | 0.001 | 0.001 |

| Resolution of A-axis | deg | 0.001 | 0.001 | 0.001 |

| Main motor power | kw | 5.5 | 5.5 | 5.5 |

| Total power | Kva | 15 | 15 | 15 |

| Main machine net weight | kg | 6000 | 6000 | 6000 |

| No. of cases | 2 cases in total | 2 cases in total | 2 cases in total |

400-Type

| Specifications | Units | GS-400CNC1 GS-400CNC2 GSK-400 GS-400CNC5 | GSD-400CNC1 GSD-400CNC2 GSD-400CNC4 GSD-400CNC5 | GST-400CNC1 GSKT-400T |

| Max. workpiece dia. | mm | 400 | 400 | 400 |

| Max module | Parallel-shaving:6 Plunge-shaving:4 | Parallel-shaving:8 Plunge-shaving:6 | Plunge-shaving:4 | |

| CNC servo axes | Z-axis Z,X-axis Z,X,A,B-axis Z,X,A,B,W-axis | Z-axis Z,X-axis Z,X,A,B-axis Z,X,A,B,W-axis | Z-axis Z,A,B-axis | |

| Max. distance between two centers | mm | 750 | 750 | 750 |

| Cutter speed(stepless) | rpm | 50-400 | 50-400 | 50-400 |

| Radial feed speed(stepless) | mm/min | 0.2-500 | 0.2-500 | 0.2-500 |

| Worktable feed speed(stepless) | mm/min | 1-500 | 1-500 | |

Center distance between cutter axis and center | mm | 140-320 | 140-320 | 140-320 |

| Max. cutter diameter | mm | 250 | 250 | 250 |

| Cutter hole diameter | mm | 63.5 | 63.5 | 63.5 |

| Cutter width | mm | 20-50 | 20-50 | 20-50 |

| Cutter head swivel angle | deg | ±20 | ±20 | ±20 |

| Resolution of linear axis | mm | 0.001 | 0.001 | 0.001 |

| Resolution of A-axis | deg | 0.001 | 0.001 | 0.001 |

| Main motor power | kw | 5.5 | 5.5 | 5.5 |

| Total power | Kva | 15 | 15 | 15 |

| Main machine net weight | kg | 6500 | 6500 | 6500 |

| No. of cases | 2 cases in total | 2 cases in total | 2 cases in total |

Standard Attachments

Independent hydraulic system

Independent automatic lubrication system

Magnetic chip conveyer

Safety switch

SIEMENS CNC system

Color LCD display

Standard RS232 interface

Machine data, specification and program disc

Electric cabinet with air conditioner

Machine status indication lamp

Working lamp

Manual chip flushing gun

Isolating vibration pads

Special tools for installation and adjustment

Optional Attachments

FANUC CNC system

Automatic loading or unloading device for disc-like and shaft gears

Auxiliary support cutter head

Expansion fixture for disc-like gears

Double-layer centers

Commercial Components

CNC system: SIEMENS or FANUC

Main hydraulic components: Taiwan KOMPASS

Key bearings: Japan NSK

Key lead screws and linear guideways: Taiwan HIWIN

Key sensors: Germany P+F

Send Inquiry to This Supplier

You May Also Like

-

Acrylic CNC Polishing Machines for Furniture IndustryNegotiableMOQ: 1 Set

-

Reliable Waterjet Cutting Machine for Stone Marble Porcleain Cutting IndustryUS$ 20000 - 40000MOQ: 1 Set

-

Custom Plastic Stainless Steel Aluminum CNC Machining PartNegotiableMOQ: 1

-

CNC Lathe Turned Machining Solid Shaft PinNegotiableMOQ: 1

-

Autopilot Flight Parts Manufacture and MIM Powder MetallurgyNegotiableMOQ: 1 Piece

-

Refrigerant gas R407NegotiableMOQ: 1 Piece

-

High Precision Machining Products of Stainless Steel Made in ChinaUS$ 1.5 - 1.5MOQ: 1000 Kilograms

-

Stainless Steel Welding Tee Pipe FittingsUS$ 0.9 - 0.9MOQ: 200 Pieces

-

OEM CNC Custom Machining Engineering Small Packaging Machine PartsUS$ 0.2 - 100MOQ: 1 Piece

-

Www.xtlaser.comHot Sale Dot Peen Pneumatic Marking MachineUS$ 1,400 - 1,600MOQ: 1 Set