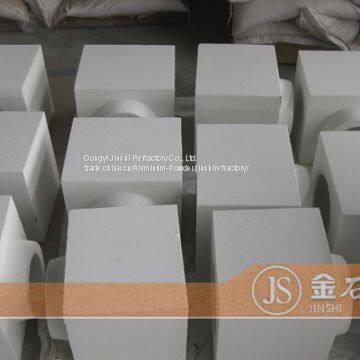

Raw materials of Corundum mullite bricks are high quality white fused alumina and high purity fused mullite. Corundum Mullite Brick is produced with high pressure and high temperature with rational proportion. With the features of high strength, high temperature resistance and excellent thermal vibration stability, corundum mullite bricks are mainly used in the key position of kilns of iron and steel, electron, petrochemical, fertilizer, non-ferrous metal and refractory industries.

Mullite bricks use mullite (3Al2O3 · 2SiO2) as raw material. Alumina content is 65% - 75%. Besides the mullite, other mineral composition can be small amounts of glass phase and cristobalite with lower alumina contains; and a small amount of corundum with higher alumina containing. The mullite brick refractoriness can be up to 1790 ℃. Load softening starting temperature: 1600 ~ 1700 ℃. Cold crushing strength: 70 ~ 260MPa. Good thermal shock resistance.

Sintered mullite brick uses high bauxite as the main raw material, added with a small amount of clay or raw bauxite as binder, processed by molding and firing.

/product-4.html

Email: js@jinshirefractory.com

Send Inquiry to This Supplier

You May Also Like

-

Alumina Bubble BrickNegotiableMOQ: 1 Cubic Meter

-

Corundum BrickNegotiableMOQ: 1 Ton

-

Corundum Mullite BrickNegotiableMOQ: 1 Tonne

-

Mullite, Sillimanite, Andalusite BrickNegotiableMOQ: 1 Ton

-

Zircon BrickNegotiableMOQ: 1 Ton

-

Corundum Mullite Light BrickNegotiableMOQ: 1 Ton

-

Silicon Carbide BricksNegotiableMOQ: 1 Ton

-

Magnesium Chrome Zircon BrickNegotiableMOQ: 1 Ton

-

High Alumina BrickNegotiableMOQ: 1 Ton

-

Low Porosity Clay BrickNegotiableMOQ: 1 Ton