Home > Products > Furnaces & Accessories > AZS Fused Cast Refractory Bricks

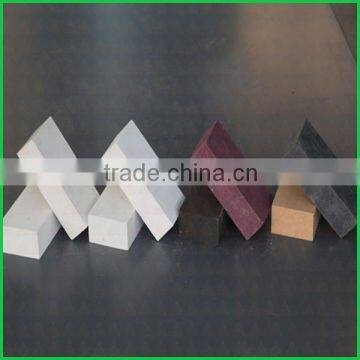

AZS Fused Cast Refractory Bricks

- Shanghai/Qingdao/Shenzhen

- T/T L/C D/P D/A Money Gram Credit Card PayPal

You May Like

-

Refractory Fused Cast AZS Brick for Glass Furnace

-

Glass Furnace Fused Cast AZS Brick 33# 36# 41#

-

JK Fused Cast AZS Refractory Brick

-

Fused Cast AZS Refractory for Glass Furnace Use

-

U Shape Elelctric High Temperature MoSi2 Heating Element High Quality Heates

-

Heating Elements Connection Furnace Fixture

Product Details

| Place of Origin | Henan, China | Shape | Brick | |

| Material | MgO-Carbon Brick | SiO2 Content (%) | 15.5 | |

| Al2O3 Content (%) | 50% | MgO Content (%) | N/A | |

| CaO Content (%) | N/A | |||

| CrO Content (%) | N/A | SiC Content (%) | N/A | |

| Model Number | JK-Fused cast AZS-004 | Brand Name | JK |

Product Description

Fused Cast AZS are the most widely used materials both in glass contact and superstructure of glass meltingfurnace. The products have passed the ISO international certified, are made of high pure material, fired at hightemperature by advanced technology, with the advantages of high strength, high compression resistance, good thermal shock resistance, good performance in high temperature, good thermal conductivity, gooderosion resistanceand so on. Widely be used for linings of furnace in industries.

Features of Fused Cast AZS

u Strong corrosion resistance

u High thermal shock resistance

u High refractoriness under load

u Low permanent linear change on reheating

u Only available for straight brick

JK-AZS33

Shapes and sizes:there are great variety of formats and shapes which are available for different forming and special machine processes.

Application: mainly used for working ends, feeder channel, side walls, superstructures, crowns, sidewalls, tank bottoms, C-shaped brick and doghouse crown.etc.

JK- AZS36

Shapes and sizes:This product is only available for straight brick.

Application:mainly used for side walls of flame furnaces with embedded melter bottoms, for total security with average pulls and campaign lengths, and superstructures, front wall, back wall, top crown in glass melting furnace.

JK- AZS41

Shapes and sizes: this product is available in a large size straight or approximate bricks and special formats and shapes whichare available for special machining processes.

Application: Mainly used for sidewalls, doghouses, throat, bottom budding, Dam blocks, electric block corners.

Physical and chemical index

Item | Behaviors | |||

AZS-33# ER 1681 | AZS-36# ER 1685 | AZS-41# ER 1711 | ||

Chemical Composition | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

SiO2 | ≤15.50 | ≤13.50 | ≤13.00 | |

Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

Bulk density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

Cold Crushing Strength Mpa | ≥300 | ≥300 | ≥300 | |

Exudation Temperature of Glass Phase | ≥1400 | ≥1400 | ≥1410 | |

Bubble Separation Ratio(1300°C×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

Anti-corrosion rate of glass liquid 1500°C×36h (mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

Apparent density (g/cm3) | PT(RN RC N) | ≥3.50 | ≥3.50 | ≥3.70 |

ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.70 | ≥3.90 | |

WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.8 | ≥4.00 | |

Cast Process

Besides, the fused cast AZS bricks can be devied into different types according its casting techniques, PT [normal casting], QX [tilt casting ] , ZWS [reinforced casting ] and WS [void-free casting].

PT The brick made by normal casting has normal shrinkage void; it is often used in the upper structure of furnace and the interface parts which touch molten glass.

QX by tilt casting, shrinkage voids focus on one side, while the other side is dense. This kind of bricks are usual sabity is located towards the bottom, and of the block that used for sidewalls.

ZWS while casting, the casting size is bigger than it is required. Most of the voids concentrate in the header which is subsequently cut off with a diamond saw, and then the block in required size is left, most used in side wall.

WS while casting, the casting size is bigger than that is required. Most of the voids concentrate in the header which is subsequently cut off with a diamond saw, and then the block in required size is left, most used in side wall and flow.

Established in 2005, HENAN JK INDUSTRY CO.,LTD is a joint-stock high Temperature Furnace/kiln manufacturing enterprise, integrating scientific research, production and marketing, specializes in the R&D and promotion of the Muffle Furnace, Tube Furnace, Vacuum Furnace, Fused Cast AZS, Fused Cast Refractory Brick etc. Our company is located in the high Technical Development Zone of Zhengzhou, China.

Our company has a group of experienced and skilled salesmen and a perfect service system. We have established customer service networks in 32 cities of our country. Our service method is flexible. Besides the traditional service methods, we offer online service and can solve problem in time. We have good sales markets in North America, Africa, East Europe, East and South Asia and other countries and regions. We have professional engineers and salesmen to serve all of our customs.

Welcome to join our teamwork!!!

Shipping as for your request

a. By DHL/Fedex............................................................................................................................................................................................YES!

b. By Sea.........................................................................................................................................................................................................YES!

c. By Air............................................................................................................................................................................................................YES!

Contacts

Contact Us

- Henan JK Industry Co., Ltd.

- Contact nameDebbie Z Chat Now

- Phone86-371-55679777

- AddressJingsan Road 56#, Zhengzhou, Henan

Product Categories

| Alumina Ceramics | Furnaces & Accessories | Graphite Crucible | New Products |

| Silicon Carbide (SiC) Ceramics | Silicon Nitride (Si3N4) Ceramics | Zirconia Ceramics |

New Products

-

L Shape Super MoSi2 Heating Element 1800

-

W Shape Hight Temperature Heating Element

-

ISO9001 Certification Ceramic Chamber Heater 12V

-

Low Thermal Conductivity Electric Ceramic Fiber Heater 1200

-

Insulation Ceramic Fiber Module 1400 C. Temp Classfication

-

Fireproof Ceramic Fiber Paper for Kilns 1430C.

-

China-double Spiral Type Sintered Silicon Carbide Rod Heater

-

Factory Sale - Silicon Carbide Electric Double Spiral Heating Element

-

Double Spiral Type Silicon Carbide Heating Element

-

ISO 9001 Certificated Double Spiral Silicon Carbide Sic Ceramic Heating Element

-

SiC Heating W Rod Type for Furnace

-

Electric Heating Rod Silicon Carbide Heater

Popular Searches

- refractory material

- tabular alumina

- calcium silicate product

- spinel

- coal tar pitch

- boron

- refractory brick

- firebrick

- clay brick

- alumina brick

- fire brick

- magnesia carbon brick

- high alumina brick

- insulation brick

- silica brick

- mullite brick

- fire clay brick

- fireclay brick

- lining brick

- building glass block

- graphite electrode

- ceramic fiber heater

- aluminum silicate blanket

- slag

- clinker

- refractory cement

- high alumina cement

- calcium aluminate cement

- graphite block

- iron powder

Recommended Products

- Energy-saving Refractory Insulation Bricks Mullite Insulation Brick for High-temperature Ethylene Cracking Furnaces

- JM23 JM26 Lightweight Refractory Mullite Insulation Brick Thermal Insulation With Cutting Processing Service

- High-Temp High-Density Mullite Insulation Brick 1770°C Fire-Resistant Refractory Brick With Cutting Service Jm26 Jm28 Jm30

- Wholesales Mullite Refractory Insulation Brick JM 23 Customized Mullite Insulating Brick for High Fire Resistance Part

- High Temperature Chemical Stability Magnesia Carbon Brick Price for Ladle Wire

- Steel Refining Furnace Refractory Fire Bricks Hot Selling and Support Customized Magnesia Carbon Bricks With CE ISO

- Wholesale Price Refractory Fire Magnesia Carbon Bricks for Hot Blast Furnace Refractories Blocks

- Refractory Bricks Mgo Magnesia Carbon Brick Magnesite Magnesium Carbon EAF BOF Converter/Ladle MgO C Brick

- Most Popular High-Strength Refractory Castables Block Powder Carbon Product Furnaces Made Mullite MGO Alumina Cement

- High Temperature Silicon Carbide Powder Refractory Castables Ciment for Precision Ceramic Kilns

- Custom Made Refractory Cement Castables Solutions Providing High Strength and Abrasion Resistant Products

- Factory Low Price Fire Bricks Insulating Porous Refractory Clay Bricks

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Refractory Material > Special Refractory Material

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Debbie Z

Hi there! Welcome to my shop. Let me know if you have any questions.

Debbie Z

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile