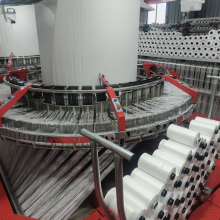

FIBC Circular Loom Machine for High-Density Polypropylene Fabric Weaving

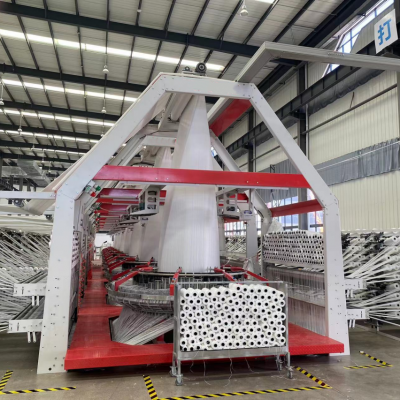

As Xuzhou Guozi Intelligent Technology Co., Ltd., based in Xuzhou, Jiangsu, China, we are dedicated to delivering advanced industrial solutions. Our FIBC Circular Loom Machine is expertly engineered for high-density polypropylene fabric weaving, ensuring superior performance in bulk container production. With years of expertise in intelligent manufacturing, this machine offers unmatched reliability and efficiency, helping you streamline operations and reduce costs. Trust our innovative approach to elevate your fabric weaving processes with precision and durability.

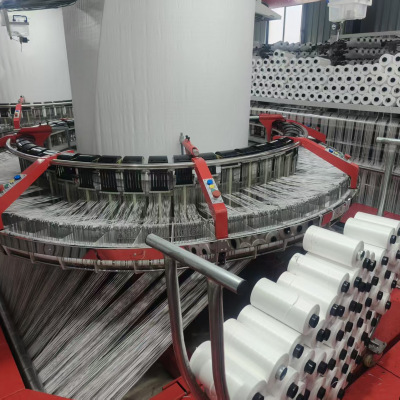

This state-of-the-art machine is designed for weaving high-density polypropylene fabric, essential for Flexible Intermediate Bulk Containers (FIBC). Key features include:

- High-Speed Weaving: Equipped with advanced mechanisms for rapid fabric production, minimizing downtime and maximizing output.

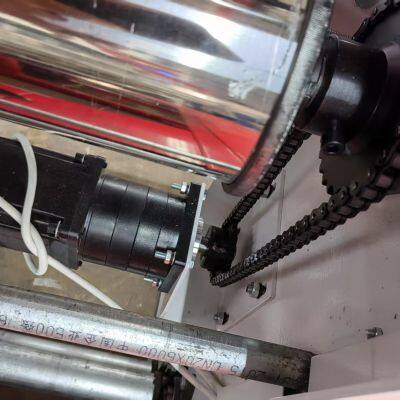

- Durable Construction: Built from high-strength steel, it withstands rigorous industrial use, ensuring longevity and low maintenance.

- Intelligent Control: Features a PLC-based system for automated operation, allowing precise adjustments to weaving patterns and tension.

- Energy Efficiency: Incorporates energy-saving motors to reduce power consumption and operational costs.

- Customizable Output: Easily adaptable for various fabric widths and densities, catering to specific client needs in bulk packaging.

Technical specifications highlight the machine's capabilities, with key parameters detailed in the table below. These ensure optimal performance in demanding environments:

| Parameter | Value | Description |

|---|---|---|

| Loom Diameter | 1000-2000 mm | Adjustable range for fabric size |

| Weaving Speed | 100-200 rpm | High-speed operation for efficiency |

| Power Consumption | 10-15 kW | Energy-efficient design |

| Machine Weight | Approx. 2000 kg | Sturdy and stable |

The advantages of this machine translate directly to client benefits. For instance, its high-density weaving capability produces robust polypropylene fabric that enhances FIBC bag strength, reducing tear risks in transport. The intelligent control system allows for easy monitoring and adjustments, lowering labor costs and minimizing errors. Additionally, the customizable features mean you can adapt it to diverse production lines, improving overall workflow efficiency. This results in faster turnaround times and higher-quality outputs, giving you a competitive edge in the bulk packaging market.

Backed by Xuzhou Guozi Intelligent Technology Co., Ltd. in Xuzhou, China, our commitment to innovation and quality ensures this machine meets rigorous industrial standards. With a strong track record in intelligent solutions, we provide reliable support and training to optimize your investment. Experience enhanced productivity and cost savings—reach out today for a personalized consultation and discover how this machine can transform your fabric weaving operations.

Frequently Asked Questions (FAQ)

-

Q: What is the primary use of this FIBC Circular Loom Machine?

A: It is designed for weaving high-density polypropylene fabric used in Flexible Intermediate Bulk Containers (FIBC), ideal for bulk packaging in industries like agriculture and chemicals. -

Q: Can the machine handle different fabric densities?

A: Yes, it offers adjustable settings for various densities, allowing customization to meet specific production requirements. -

Q: What is the typical production capacity?

A: With high-speed weaving, it achieves efficient output rates, but exact capacity is customizable based on loom settings and operational parameters. -

Q: Is training provided for operators?

A: Operational training is available upon request to ensure smooth integration and safe usage. -

Q: How energy-efficient is this machine?

A: It incorporates energy-saving components, reducing power consumption by up to 20% compared to conventional models, which lowers operational costs. -

Q: What maintenance is required?

A: Designed for low maintenance, it features easy-access components for routine checks, with service intervals recommended every 500 hours of operation. -

Q: Can it be integrated into existing production lines?

A: Absolutely, its compact dimensions and adaptable controls make it suitable for seamless integration into various setups. -

Q: What safety features are included?

A> Standard safety mechanisms, such as emergency stops and overload protection, are built-in to ensure operator safety during use.

Send Inquiry to This Supplier

You May Also Like

-

Robust FIBC Circular Loom Supporting Various PP Woven Bag SpecificationsNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom for PP Woven Bags With Automatic Control SystemNegotiableMOQ: 1 Set

-

Energy Saving Circular Loom Machine for FIBC and Big Bag ManufacturingNegotiableMOQ: 1 Set

-

Precision Circular Loom Machine for High-Quality FIBC Woven FabricNegotiableMOQ: 1 Set

-

Automatic Circular Loom Machine for Woven Sacks and FIBC Jumbo Bags ManufacturingNegotiableMOQ: 1 Set

-

Advanced Circular Loom Weaving Machine for Jumbo Bulk Bag ProductionNegotiableMOQ: 1 Set

-

High-Speed FIBC Circular Loom Machine for Jumbo Bag Production With 4 Shuttles SystemNegotiableMOQ: 1 Set

-

High-Performance FIBC Circular Loom for PP Woven Bag Production With Advanced Weaving TechnologyNegotiableMOQ: 1 Set

-

Efficient FIBC Circular Loom Machinery With Low Maintenance Design for Continuous Woven Bag OutputNegotiableMOQ: 1 Set

-

Energy-Saving Circular Loom Equipment for FIBC and Jumbo Bag Manufacturing IndustriesNegotiableMOQ: 1 Set