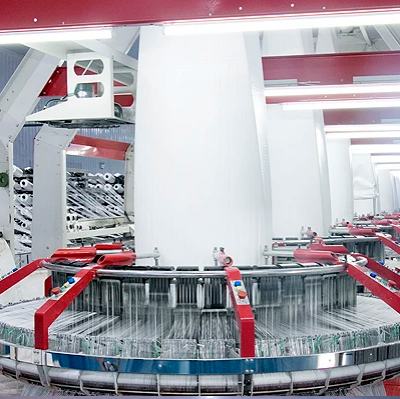

Energy-Saving Circular Loom Equipment for FIBC and Jumbo Bag Manufacturing Industries

As a leading innovator in industrial textile machinery, Xuzhou Guozi Intelligent Technology Co., Ltd. proudly presents our advanced Circular Loom Equipment engineered specifically for FIBC (Flexible Intermediate Bulk Container) and jumbo bag manufacturers. Based in China's manufacturing hub of Xuzhou, Jiangsu, we've developed this solution to address critical industry challenges including energy consumption reduction and production efficiency optimization. Our circular looms represent over a decade of R&D in automated weaving technology, delivering measurable cost savings while maintaining rigorous quality standards for heavy-duty bag production.

The core engineering philosophy behind this equipment focuses on three pillars: sustainable operation, precision weaving, and minimal maintenance requirements. Through proprietary motor technology and intelligent power management systems, these circular looms achieve energy savings of up to 30% compared to conventional models. The modular design allows for rapid configuration changes between different bag specifications, reducing downtime during product changeovers. Key technical specifications include:

- Advanced Tension Control: Laser-guided synchronous monitoring maintains consistent weave density

- Multi-Spool Capacity: Simultaneous processing of 8-16 yarn spools (depending on model)

- Smart Fault Detection: Real-time diagnostics for broken warp/weft threads

- Ergonomic Design: 360° accessible workstations with safety interlocks

Technical specifications vary across our product range to accommodate different production scales:

| Model Series | Weaving Diameter | Max. Fabric Width | Power Consumption | Daily Output Capacity |

|---|---|---|---|---|

| GL-2000 | 2.0m | 3.2m | 18kW | 800-1000 bags |

| GL-2800 | 2.8m | 3.8m | 24kW | 1200-1500 bags |

| GL-4000 | 4.0m | 4.5m | 32kW | 2000-2400 bags |

Operational advantages extend beyond the specifications sheet. Manufacturers report 15-20% reduction in material waste due to precision yarn placement and automated edge trimming. The equipment's compatibility with polypropylene, polyester, and blended fibers provides material flexibility without retrofitting. For maintenance teams, the color-coded component system and accessible service points reduce technical downtime by approximately 40%. These cumulative benefits translate to ROI within 14-18 months for medium-scale operations.

Backed by Xuzhou Guozi's nationwide service network across China, each circular loom comes with comprehensive technical support including:

- On-site installation supervision by certified engineers

- Operator training programs covering routine maintenance

- Remote diagnostics capability through integrated IoT modules

- Priority spare parts dispatch from our Jiangsu headquarters

With documented case studies demonstrating 98.5% operational uptime in continuous production environments, our circular looms have become the backbone of numerous FIBC manufacturing facilities. We invite bulk bag producers to experience the Guozi difference through scheduled demonstration runs at our Xuzhou technology center, where you can test-weave your specific materials and verify performance metrics firsthand.

FAQ

Q: What fiber types can this circular loom process?

A: The equipment is compatible with polypropylene (PP), polyethylene (PE), and polyester (PET) fibers ranging from 800-2400 denier. Custom configurations for specialized fibers are available upon request.

Q: How does the energy-saving feature work?

A: Our proprietary Eco-Drive system regulates motor output based on real-time weaving tension, reducing power consumption during low-intensity operations. The regenerative braking system captures kinetic energy during deceleration phases.

Q: What safety certifications does the equipment have?

A: All models comply with GB national standards for industrial machinery safety. Specific certifications can be provided upon inquiry for regional requirements.

Q: Can existing production lines integrate this equipment?

A: Yes, our engineering team provides transition planning services including floor layout optimization and electrical compatibility assessments for seamless integration.

Q: What is the typical installation timeframe?

A: Standard installation requires 3-5 working days with our supervision, excluding facility preparation. Turnkey project timelines vary based on factory conditions.

Q: How often does the machine require maintenance?

A: Routine lubrication and inspection every 500 operating hours, with major service intervals at 4,000 hours. The touchscreen interface provides maintenance reminders and checklists.

Q: Are custom widths beyond 4 meters available?

A: Specialized wide-format models can be engineered for specific project requirements. Please contact our technical team for feasibility studies.

Q: What warranty coverage is provided?

A: Standard 18-month warranty on core components, extendable through service agreements. Full terms are detailed in our sales contracts.

Send Inquiry to This Supplier

You May Also Like

-

High Speed PP Woven Sack Making Unit for Durable Packaging Solutions in Agricultural SectorNegotiableMOQ: 1 Set

-

PP Woven Bag Manufacturing Equipment With Advanced Control System and Customizable SizesNegotiableMOQ: 1 Set

-

Industrial Woven Polypropylene Bag Production Line for Food and AgricultureNegotiableMOQ: 1 Set

-

Turnkey Woven Bag Production Solution With Customizable Capacity and DimensionsNegotiableMOQ: 1 Set

-

Integrated Woven Bag Production Line Featuring Edge Trimming and Bottom SewingNegotiableMOQ: 1 Set

-

Automatic PP Woven Fabric Bag Making Machine With Quality Control SystemNegotiableMOQ: 1 Set

-

Heavy-Duty Woven Bag Manufacturing Equipment for 10-50kg Product PackagingNegotiableMOQ: 1 Set

-

Eco-Friendly PP Woven Bag Making Machine for Cement and Chemical PackagingNegotiableMOQ: 1 Set

-

Advanced Circular Loom for Jumbo Bag Making With Electronic Control PanelNegotiableMOQ: 1 Set

-

Industrial Circular Weaving Loom for Bulk FIBC Fabric, 4-8 Shuttles ConfigurationNegotiableMOQ: 1 Set