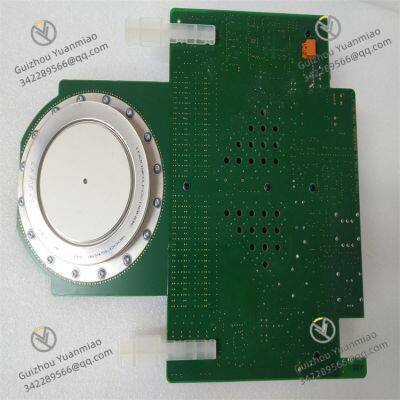

ABB 3BHE039203R0101 GVC736CE101 Thyristor Rectifier

ABB 3BHE039203R0101 (Model: GVC736CE101) is an industrial-grade high-performance thyristor rectifier, belonging to ABB's power electronics product line. It is mainly positioned as a core equipment for power conversion and control, focusing on accurately converting alternating current (AC) to direct current (DC), while realizing efficient control and real-time monitoring of the rectification system. Custom-designed for high-power industrial scenarios requiring adjustable DC power supplies, this rectifier integrates advanced thyristor technology with the advantages of IGCT (Integrated Gate-Commutated Thyristor), adopts high-quality components and precision manufacturing processes, and features high efficiency, high power density and high stability. It can be seamlessly compatible with industrial rectification systems, high-power motor drives, excitation systems and other equipment, undertaking the core tasks of power conversion, load driving and system protection. Its modular design facilitates installation and maintenance, supports remote monitoring and fault diagnosis, and can effectively resist the impact of complex working conditions on industrial sites. It is widely used in metallurgy, electric power, electroplating and electrolysis, new energy and other fields, with original factory quality control and a comprehensive spare part adaptation system. It can be used as a key spare part to meet the maintenance and upgrading needs of existing rectification systems, providing reliable power conversion guarantee for the stable and efficient operation of industrial production.

I. Positioning and Value

As a core equipment of industrial power conversion systems, this thyristor rectifier effectively fills the demand gap for precise rectification and efficient power control in high-power scenarios. With advanced thyristor technology, it achieves efficient conversion of AC to DC with high conversion efficiency and low energy consumption, greatly reducing system heat dissipation requirements and operating costs. Its integrated precise control and monitoring functions can real-time grasp the operating status of the rectification system, avoid damage to equipment caused by voltage and current fluctuations, and improve the stability and reliability of system operation. The modular and remotely maintainable design allows fault diagnosis and component replacement without complex disassembly, shortening downtime and reducing operation and maintenance costs. At the same time, it is compatible with a variety of industrial high-power scenarios and mainstream control systems, reducing system integration difficulty and transformation cycle, providing stable and controllable DC power support for key industrial links such as metallurgical electrolysis, motor excitation and HVDC transmission auxiliary, meeting the needs of long-term continuous industrial operation.

II. Technical Parameters

1. Electrical and Rectification Parameters

Parameter Item | Specification Details |

|---|---|

Core Function | AC to DC conversion, precise control and real-time monitoring of rectification system, load driving and overload/overheat protection, supporting remote monitoring and fault diagnosis |

Core Technology | Thyristor technology, integrated with the advantages of IGCT (Integrated Gate-Commutated Thyristor), asymmetric integrated design with reduced number of components to improve operational reliability |

Rated Input Voltage | 380V AC-480V AC (three-phase), 50/60Hz universal, compatible with industrial standard high-voltage power supply systems |

Rated Output Voltage | 0-400V DC continuously adjustable, output voltage accuracy ≤±1%, meeting the DC power supply needs of different loads |

Rated Output Current | 50A-100A (rated load), peak current up to 200A (short-term tolerance), suitable for high-power load driving |

Conversion Efficiency | ≥98% (under rated load), high power density design, reducing energy consumption and heat dissipation requirements, in line with industrial energy-saving concepts |

Electrical Isolation | Electrical isolation between input/output circuits and control circuit (isolation voltage ≥2500V AC), effectively avoiding signal interference and crosstalk, compliant with IEC 60664 standard |

2. Environmental and Reliability Parameters

Parameter Item | Specification Details |

|---|---|

Operating Temperature | -20℃ to +75℃; stable operation in a wide temperature range, adapting to complex industrial on-site and equipment room environments with high and low temperatures |

Storage Temperature | -40℃ to +85℃; facilitating transportation and long-term storage, adapting to transportation and storage conditions in different regions |

Environmental Humidity | 5%-95% (non-condensing); resistant to erosion from humid environments, adapting to humid working conditions such as electroplating and water treatment |

Protection Grade | IP20 (body), IP40 optional with protective cover; dust and moisture proof, suitable for cabinet installation scenarios, effectively preventing dust from entering and damaging internal circuits |

Anti-interference Performance | Compliant with IEC 61000-4-2/4/5 standards; resistant to electrostatic discharge, surges and electrical fast transient bursts, adapting to industrial strong electromagnetic environments |

Mean Time Between Failures (MTBF) | >100,000 hours; adopting high-quality materials and manufacturing processes to ensure long-term stable operation of the equipment and reduce the frequency of spare part replacement |

3. Structural and Installation Parameters

Parameter Item | Specification Details |

|---|---|

Structural Form | Modular compact design with reasonable component layout; reducing the number of components to improve operational reliability, while saving distribution cabinet installation space, adapting to high-density cabinet layout |

Overall Dimensions | 127mm (width) ×127mm (height) ×127mm (depth); standard industrial module size, compatible with mainstream distribution cabinet specifications, weight approx. 0.4kg |

Mounting Method | 35mm standard DIN rail snap-on installation or bolt fixation; easy to install, enabling quick assembly and replacement, complying with industrial standard installation specifications |

Wiring Method | Screw terminal wiring; firm contact, anti-vibration, facilitating wiring and later maintenance; adaptable to 1.5-4.0mm² specification cables, supporting separate wiring for main circuit and control circuit |

Maintenance Features | Supports remote monitoring and maintenance, facilitating users to troubleshoot and repair faults; quick disassembly without complex tools, reducing maintenance difficulty |

III. Features and Advantages

High Efficiency and Energy Saving, Lower Energy Consumption: Adopting advanced thyristor technology and high power density design, the conversion efficiency is ≥98%, which greatly reduces energy consumption, reduces the investment cost of heat dissipation equipment, and conforms to the concept of industrial green energy saving.

High Reliability and Stable Operation: Selected high-quality components and precision manufacturing processes, integrated with IGCT technology advantages, reduced the number of components, and improved equipment durability; full isolation design of input/output and control circuits, effectively resisting electromagnetic interference and voltage fluctuations, avoiding signal distortion and equipment faults, ensuring long-term stable operation of the rectification system.

Precise Control and Wide Adaptability: The output voltage is continuously adjustable from 0 to 400V DC, with voltage accuracy ≤±1%, which can accurately match the DC power supply needs of different high-power loads; compatible with 380V AC-480V AC three-phase input, adapting to global mainstream industrial high-voltage power supply systems, and widely applicable to various rectification application scenarios.

Convenient Operation and Maintenance with Controllable Costs: Modular compact design and standardized installation method enable quick installation and replacement; supports remote monitoring and fault diagnosis, and cooperates with indicator lights to display operating status and fault information, facilitating quick problem location, reducing downtime and operation and maintenance workload; high MTBF design with low failure probability, reducing the frequency of spare part replacement and operation and maintenance costs.

Comprehensive Safety Protection: Built-in overheat, overload, overcurrent and overvoltage protection functions, which can automatically cut off power or alarm to protect equipment and loads from damage; some models have manual and automatic reset options, which can be flexibly selected according to actual needs, improving operational safety and convenience.

IV. Application Fields

Metallurgical Industry: Adapted to metallurgical electrolysis scenarios such as electrolytic aluminum and electrolytic copper, providing stable and adjustable high-power DC power supply, controlling electrode current, ensuring stable and efficient metallurgical process, and improving product quality.

Electric Power and Motor Drive: In the excitation systems of power plants and substations, providing precise excitation current for synchronous motor rotors; in high-power DC motor drive scenarios (such as rolling mills and mine hoists), providing stable DC power supply to realize precise control of motor speed.

Electroplating and Electrolysis Industry: In industrial electroplating, electrochemical treatment and other scenarios, providing stable and adjustable DC power supply to ensure uniform plating and sufficient electrolytic reaction, improving production efficiency and product qualification rate.

Other High-Power Scenarios: HVDC transmission auxiliary systems, induction heating power supplies, large-capacity battery pack charging, DC arc furnace power supplies and other scenarios, undertaking power conversion and stable power supply tasks, adapting to various high-power industrial needs requiring adjustable DC power supplies.

Send Inquiry to This Supplier

You May Also Like

-

ABB 12MX04G-V0002 3EGM030900R0002 Digital I/O Expansion ModuleNegotiableMOQ: 1 Piece

-

ABB 12KX02F-V0002 GVT8703200R0002 Digital I/O Expansion ModuleNegotiableMOQ: 1 Piece

-

ABB GRBTU 3BSE013175R1 DP Slave Communication AdapterNegotiableMOQ: 1 Piece

-

ABB 500TRM02 1MRB150011R1NegotiableMOQ: 1 Piece

-

ABB RED615 HCDCACADAHC2BNN11E Feeder ProtectionNegotiableMOQ: 1 Piece

-

ABB PPC322AEV01 HIEE300697R1 Excitation Control BoardNegotiableMOQ: 1 Piece

-

ABB PDD205A0121 3BHE025335R0121 Circuit Board ModuleNegotiableMOQ: 1 Piece

-

ABB PPD512A10-454000 3BHE040375R103E Industrial Control ModuleNegotiableMOQ: 1 Piece

-

ABB RF533 3BSE014227R1 Subrack 12SU Including BackplaneNegotiableMOQ: 1 Piece

-

ABB PPD513A-23-111615 Magnetic Excitation ControllerNegotiableMOQ: 1 Piece