Versatile Circular Loom for Bulk Bag Production Featuring User-Friendly Control System

As a leading innovator in textile machinery manufacturing, Xuzhou Guozi Intelligent Technology Co., Ltd. proudly presents our advanced Circular Loom engineered specifically for bulk bag production. Based in Xuzhou, Jiangsu – China's renowned manufacturing hub – we combine precision engineering with practical innovation to deliver equipment that transforms your production efficiency. This versatile machine features our proprietary control system designed through extensive operator feedback, ensuring both novice and experienced technicians can achieve optimal output with minimal training.

The core value of this circular weaving solution lies in its adaptability across diverse polypropylene tape specifications while maintaining consistent fabric quality. Unlike conventional looms requiring frequent adjustments, our intelligent tension management system automatically compensates for material variations during continuous operation. This results in a 15-20% reduction in yarn breakage and significantly lowers material waste – critical factors in high-volume FIBC manufacturing where every meter of fabric impacts profitability.

Technical Specifications & Performance Advantages:

- Modular Construction – Quick-change components allow reconfiguration for different bag dimensions within 30 minutes

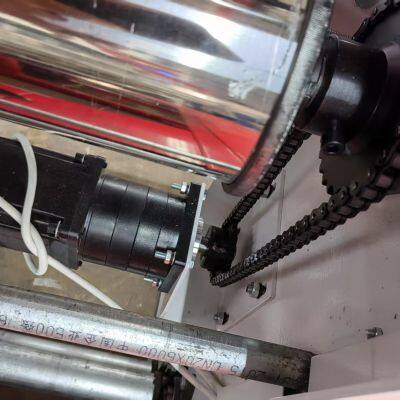

- Precision Weft Insertion – Patented shuttle mechanism achieves 220-250 picks/minute with ±2% density consistency

- Energy Optimization – Regenerative drive system reduces power consumption by 18% compared to standard models

- Multi-layer Fabric Capability – Simultaneously weaves up to 4 layers for reinforced bulk bag designs

| Parameter | Standard Range | Custom Options |

| Fabric Width | 1000-1500 mm | 800-2000 mm |

| Tape Width | 2.5-5 mm | 1.8-8 mm |

| Motor Power | 7.5 kW | 5.5-11 kW |

| Production Speed | 12-18 m²/h | Variable control |

Operational benefits extend beyond technical specifications. The ergonomic design features centralized lubrication points and front-access maintenance panels that cut downtime by 40% during routine servicing. Color-coded error indicators on the touchscreen interface instantly identify over 30 potential fault conditions – from thread jams to tension irregularities – enabling corrective action before defects occur. For bulk bag producers facing labor shortages, this loom's semi-automatic threading system allows one operator to manage two machines simultaneously without compromising output quality.

Backed by Xuzhou Guozi's 15-year expertise in industrial weaving solutions, this circular loom incorporates field-tested reliability with over 200 units operating in challenging environments worldwide. Our Jiangsu manufacturing facility utilizes ISO-compliant production processes (certification available upon request), and each machine undergoes 72-hour continuous operation testing before shipment. Clients consistently report ROI within 14 months through reduced waste and increased throughput, particularly when producing high-specification FIBCs for construction materials and chemical products.

Partner with us to elevate your bulk bag manufacturing capabilities. Contact our engineering team in Xuzhou today for a customized productivity analysis and discover how our user-friendly technology can become your competitive advantage in the global packaging market.

Frequently Asked Questions:

Q1: What types of polypropylene tapes are compatible with this loom?

The machine accommodates both flat and split PP tapes ranging from 80-250 denier. Specialized guides prevent fibrillation during high-speed weaving of recycled material blends.

Q2: How does the control system simplify operation?

Our graphical interface displays real-time production metrics and provides step-by-step setup wizards. Memory presets store parameters for different bag specifications, enabling changeovers with single-touch commands.

Q3: Can the loom produce UV-resistant or anti-static fabrics?

Yes, specialized creels and tensioners accommodate additive-coated tapes. Optional static-dissipative components can be integrated for explosive environment applications.

Q4: What maintenance routines are required?

Daily cleaning and weekly lubrication of critical points ensure optimal performance. The system generates automated maintenance reminders based on operational hours logged.

Q5: Is technical training included?

We provide comprehensive on-site training covering operation, troubleshooting, and preventive maintenance. Video manuals and remote support are also available.

Q6: What safety features are incorporated?

Emergency stop buttons, shuttle guards, and infrared motion sensors create multiple protection layers. Safety interlocks prevent operation during access panel openings.

Send Inquiry to This Supplier

You May Also Like

-

PP Woven Bag Manufacturing Equipment With Advanced Control System and Customizable SizesNegotiableMOQ: 1 Set

-

Industrial Woven Polypropylene Bag Production Line for Food and AgricultureNegotiableMOQ: 1 Set

-

Turnkey Woven Bag Production Solution With Customizable Capacity and DimensionsNegotiableMOQ: 1 Set

-

Integrated Woven Bag Production Line Featuring Edge Trimming and Bottom SewingNegotiableMOQ: 1 Set

-

Automatic PP Woven Fabric Bag Making Machine With Quality Control SystemNegotiableMOQ: 1 Set

-

Heavy-Duty Woven Bag Manufacturing Equipment for 10-50kg Product PackagingNegotiableMOQ: 1 Set

-

Eco-Friendly PP Woven Bag Making Machine for Cement and Chemical PackagingNegotiableMOQ: 1 Set

-

Advanced Circular Loom for Jumbo Bag Making With Electronic Control PanelNegotiableMOQ: 1 Set

-

Industrial Circular Weaving Loom for Bulk FIBC Fabric, 4-8 Shuttles ConfigurationNegotiableMOQ: 1 Set

-

Precision Circular Loom for FIBC Material With Automatic Brake SystemNegotiableMOQ: 1 Set