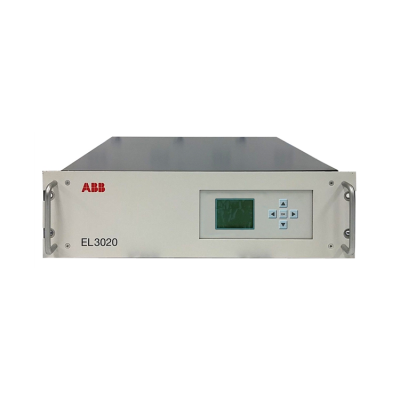

ABB EL3020 Gas Analyzer

The ABB EL3020 is a 19-inch rack-mount continuous gas analyzer belonging to the EasyLine series, specially designed for industrial process control and flue gas emission monitoring. It supports the accurate and continuous measurement of multi-component gases (such as CO, CO₂, NO, SO₂, O₂, CH₄, etc.). Adopting a modular multi-technology platform (including Uras26 infrared, Limas23 ultraviolet, Magnos28 paramagnetic oxygen, Caldos27 thermal conductivity, etc.), it features automatic calibration, a comprehensive self-diagnosis function and industrial bus communication capability, enabling seamless integration into DCS/PLC systems. It is suitable for both regular workshop operations and compliance emission monitoring scenarios, and certain configurations can be used for the detection of non-flammable/compliant flammable gases in specific hazardous areas.

I. Technical Parameters

Measurement Performance

Supports the simultaneous measurement of up to 5 gas components; the measurement range covers 0–100% gas concentration with an accuracy of ±0.5% of the full scale; the typical T90 response time is ≤10 s (depending on the technical module).Optional measurement technologies: Uras26 infrared photometer (for measuring CO/CO₂/NO/SO₂/CH₄), Limas23 ultraviolet (for measuring NO/NO₂/SO₂), Magnos28 paramagnetic oxygen (for measuring O₂), Caldos27 thermal conductivity (for measuring H₂, etc.).Equipped with automatic calibration (dual modes of air/calibration gas, including automatic control of pumps and valves); optional QAL3 data storage and audit trail functions are available.

Power Supply and Signal Communication

Power supply: 230 V AC, 50/60 Hz; power consumption varies with module configuration, with a standard configuration of ≤50 VA.Output: 4–20 mA analog signals (multi-channel); communication supports Modbus RTU/TCP, PROFIBUS DP and Ethernet IP.HMI: Menu-driven Chinese/English operation interface with clear text status and fault prompts.

Environmental Adaptation and Protection

Operating temperature: +5°C to +45°C (+5°C to +40°C when combined with Uras26); storage temperature: -25°C to +65°C.Protection rating: IP20 (for 19-inch rack mounting); configurations with stainless steel gas circuits and connectors can obtain II 3G Ex nA II T4 X explosion-proof certification.Electromagnetic interference resistance complies with the EN 61326 industrial standard.

Structure and Installation

19-inch 3U standard rack mounting; optional built-in gas sampling system (solenoid valves, pumps, filters, flow sensors).A side clearance of ≥3 cm must be reserved for cabinet installation; an air exchange rate of ≥1 time per hour is required in closed cabinets.Weight is approximately 12 kg; featuring a modular plug-and-play design for easy maintenance and module replacement.

II. Features and Advantages

Flexible modular configuration: Infrared/ultraviolet/paramagnetic oxygen/thermal conductivity modules can be combined on demand, and measurable components can be expanded without replacing the entire unit; an optional built-in gas sampling system simplifies on-site gas circuit construction.

High accuracy, reliability and strong compliance: Measurement accuracy and repeatability meet the standards for industrial processes and EN emission monitoring; the combination of automatic calibration, self-diagnosis and optional QAL3 reduces human errors and compliance risks.

Easy integration and operation & maintenance: Direct 19-inch rack mounting into cabinets, full compatibility with industrial buses and seamless integration into DCS/PLC systems; menu-driven operation with direct display of fault codes, and the self-diagnosis function can locate sensor/gas circuit/communication faults with a short mean time to repair.

High scenario adaptability: The standard IP20 configuration is suitable for control rooms/cabinet rooms; the stainless steel gas circuit with explosion-proof configuration can be used for the measurement of non-flammable/compliant flammable gases in Zone 2/II 3G; the temperature range covers most indoor industrial working conditions.

III. Application Fields

Industrial process control: Petrochemical cracking/syngas monitoring, flue gas analysis (O₂/CO/NOx) of power plant boilers, gas composition measurement of blast furnaces/converters in the steel industry, CO₂/O₂ concentration control in papermaking/food fermentation processes.

Environmental emission monitoring: Continuous monitoring of SO₂/NOx/HCl in flue gas from waste incineration plants, compliance detection of tail gas in chemical industrial parks, CH₄/CO₂ content analysis in biogas projects.

Energy and public utilities: CH₄ purity and trace impurity detection in gas transmission and distribution, H₂ concentration and CO residual monitoring in hydrogen production.

Laboratories and third-party testing: Online gas analysis platforms, gas component tracking in process R&D.

IV. Key Installation and Maintenance Points

Confirm the gas circuit material (stainless steel/PTFE) and pressure range before installation; it is strictly forbidden to use in explosive mixture working conditions of flammable gas/air/oxygen (unless the corresponding explosion-proof configuration certification is obtained).

Operate only after power off and cooling; separate power lines, analog lines and communication lines during wiring, and ensure proper shielding and grounding to avoid interference.

Routine maintenance: Inspect gas circuit leaks and clean filters every 6 months; perform a full-scale calibration with calibration gas every 12 months; shorten the cycle to 3–6 months in dusty/high-humidity environments.

Avoid direct UV exposure to the plastic housing parts; prevent mechanical impact from damaging optical/paramagnetic modules; seal the gas circuit and power on regularly for moisture proofing when the device is out of service for a long time.

Send Inquiry to This Supplier

You May Also Like

-

ABB 500SCM01 1MRE450004R1 Communication Coupler ModuleNegotiableMOQ: 1 Piece

-

ABB 1TGE120010R1300 Control RelayNegotiableMOQ: 1 Piece

-

ABB 12NG02I-V0012 GVT8703700R0012 Digital I/O Expansion ModuleNegotiableMOQ: 1 Piece

-

ABB 12KG04J-V0002 3EGM031400R0002 Digital I/O Expansion ModuleNegotiableMOQ: 1 Piece

-

ABB 3BHE024415R0101 GVC714A101 Thyristor RectifierNegotiableMOQ: 1 Piece

-

ABB PCD235B1101 3BHE032025R1101 Processor ModuleNegotiableMOQ: 1 Piece

-

ABB 12MX04F-V0002 3EGM030900R0002 Digital I/O Expansion ModuleNegotiableMOQ: 1 Piece

-

ABB PFCL201CE-50KN 3BSX802939-108 Tension/Vertical Force Measurement SensorNegotiableMOQ: 1 Piece

-

ABB 3BHE039203R0101 GVC736CE101 Thyristor RectifierNegotiableMOQ: 1 Piece

-

ABB UFD203A101 3BHE019361R0101 Power Supply ModuleNegotiableMOQ: 1 Piece