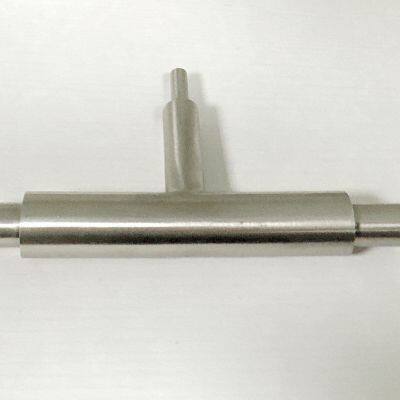

High-Performance Double Pipe Bends, ASTM A403 WP304/316, Custom Sizes 1/2" to 24"

Shanghai Quanbao Electronic Materials Technology Co., Ltd., based in Shanghai, China, specializes in manufacturing premium High-Performance Double Pipe Bends designed for demanding industrial applications. Our ASTM A403 WP304/316 stainless steel pipe bends deliver exceptional corrosion resistance and structural integrity, ensuring long-term reliability in critical piping systems.

Engineered for precision, these custom-sized bends (1/2" to 24") minimize flow turbulence and pressure drops while accommodating complex routing requirements. With rigorous quality control from raw material selection to final inspection, we provide solutions that reduce maintenance costs and downtime for global clients in chemical, petrochemical, and energy sectors.

Core Advantages: Enhanced durability against pitting/crevice corrosion in chloride environments.

Custom Flexibility: Tailored dimensions and angles (30°-180°) to match project specifications.

Efficiency Optimization: Smooth inner surface reduces friction loss by up to 15% compared to standard elbows.

| Parameter | Specification |

|---|---|

| Material Grades | ASTM A403 WP304/304L/316/316L |

| Wall Thickness | Schedule 5S to XXS (Customizable) |

| Bend Radius | 1.5D to 5D (Standard or Request) |

| Temperature Range | -196°C to 700°C |

| Testing | Hydrostatic, PMI, Dye Penetrant (Optional) |

Our manufacturing process employs cold forming and solution annealing to maintain metallurgical properties, while TIG welding ensures joint consistency for high-purity applications. The bends undergo passivation to enhance oxide layer formation, significantly extending service life in aggressive media like acids and saltwater.

As an established supplier from Shanghai’s industrial hub, we combine technical expertise with responsive customization. Over 80% of our products are exported to Europe and North America, where they meet stringent operational demands. Partner with us for:

Third-party inspection acceptance (SGS/BV available upon request)

Traceable material certifications with mill test reports

Just-in-time delivery for urgent project timelines

FAQ:

Q: Can you provide bends for high-pressure steam lines?

A: Yes, our Schedule 80 and XXS thickness options are suitable for pressures up to 1,500 PSI (subject to size verification).Q: Are non-standard angles like 45° or 90° available?

A: We manufacture all common angles (22.5°, 45°, 90°, 180°) and accept custom angle requests.Q: Do you offer documentation for material traceability?

A: Full EN 10204 3.1 certification is provided with each batch.Q: What packaging is used for overseas shipping?

A: Bends are plastic-capped and packed in wooden crates with anti-corrosion VCI coating.Q: How do WP304 and WP316 differ in performance?

A: WP316 contains molybdenum for superior acid/salt resistance; WP304 is cost-effective for general corrosive environments.Q: Can I request sample testing before bulk orders?

A: Samples are available with NACE MR0175 testing upon request.

Leverage our 12-year expertise in precision piping components to optimize your fluid systems. Contact Shanghai Quanbao today for competitive quotations and engineering support – your reliable partner for ASTM-compliant stainless steel solutions.

Send Inquiry to This Supplier

You May Also Like

-

Reliable Double Ferrule Tube Fittings With Free Technical SupportNegotiableMOQ: 500 Pieces

-

Precision Double Ferrule Tube Fittings for Hydraulic and Pneumatic ApplicationsNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Compression Fittings With 5000 PSI RatingNegotiableMOQ: 500 Pieces

-

ASME BPE Compliant Double Ferrule Fittings for Pharmaceutical PipingNegotiableMOQ: 500 Pieces

-

304 Stainless Steel Double Ferrule Pipe Fittings for High-Pressure SystemsNegotiableMOQ: 500 Pieces

-

Double Ferrule Pipe Fittings With Leak-Proof Design for Chemical TransferNegotiableMOQ: 500 Pieces

-

Durable Stainless Steel Double Ferrule Fittings With 10-Year WarrantyNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Fittings for Food Processing EquipmentNegotiableMOQ: 500 Pieces

-

Corrosion-Resistant Double Ferrule Pipe Fittings for Marine EnvironmentsNegotiableMOQ: 500 Pieces

-

316L Stainless Steel Double Ferrule Fittings With Mill Test ReportNegotiableMOQ: 500 Pieces