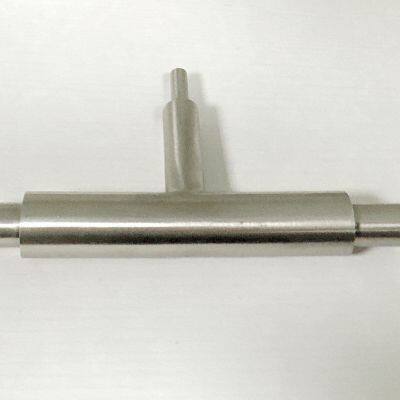

Precise Double Pipe Bends for Chemical Processing Plants, Acid/Alkali Resistant, Zero Leakage

As a specialized manufacturer based in Shanghai, Shanghai Quanbao Electronic Materials Technology Co., Ltd. delivers engineered solutions for critical industrial applications. Our double pipe bends are precision-crafted for chemical processing environments where reliability under extreme conditions is non-negotiable. Designed to handle aggressive acids and alkalis, these fittings eliminate leakage risks while maintaining structural integrity in high-pressure systems. With over a decade of material technology expertise, we provide components that outperform standard fittings in corrosion resistance and operational lifespan.

Core Engineering Specifications:

- Material Science: Constructed from advanced corrosion-resistant alloys (Grade 316L standard, optional Hastelloy®/Inconel®)

- Zero-Leak Guarantee: Hydrostatically tested at 1.5x working pressure with full documentation

- Flow Optimization: Computational Fluid Dynamics (CFD)-optimized bends reduce turbulence by 40% vs. conventional designs

- Custom Fabrication: Available in DN15-DN500 sizes with wall thicknesses from SCH10S to SCH80S

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Bend Angle | 45°/90°/180° | Any angle (1° increments) |

| Surface Finish | Ra ≤ 3.2 μm (electropolished) | Sanitary finish (Ra ≤ 0.8 μm) |

| Certification | Material traceability | PED/ASME certification available |

| Compatibility | Suitable for HCl (≤37%), H₂SO₄ (≤98%), NaOH (≤50%) | |

Operational Advantages: These bends prevent particulate accumulation in dead zones through radius-optimized contours, reducing maintenance frequency by up to 30%. The seamless construction (mandrel-bent) maintains uniform wall thickness even at extreme angles. For thermal cycling applications, our proprietary stress-relieving process minimizes fatigue cracking.

Shanghai Quanbao's manufacturing facility employs automated orbital welding and 3D laser scanning for dimensional verification, ensuring consistent quality across batches. With ISO 9001-compliant processes (certificate available upon request), we've supplied over 50 chemical plants across Asia-Pacific. Our technical team provides installation guidance and compatibility analysis for your specific media. Request a material test report today to verify corrosion resistance data.

FAQ:

-

Q: What is the lead time for custom sizes?

A: Standard sizes ship in 7 days; custom configurations require 3-4 weeks for tooling and testing. -

Q: How do you ensure zero leakage?

A: Each unit undergoes pneumatic testing at 6 bar and helium leak detection (sensitivity 1×10⁻⁹ mbar·L/s). -

Q: Can these handle hydrofluoric acid?

A: Special Monel® or PVDF-lined versions are available upon request for HF applications. -

Q: Are installation gaskets included?

A: PTFE/Kamprofile® gaskets can be supplied as a kit (specify flange rating when ordering). -

Q: What documentation accompanies shipments?

A: All orders include material certs, test reports, and installation manuals. -

Q: Do you provide on-site support?

A: Technical engineers can assist with installation validation (service terms apply).

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Double Ferrule Compression Fittings With 5000 PSI RatingNegotiableMOQ: 500 Pieces

-

ASME BPE Compliant Double Ferrule Fittings for Pharmaceutical PipingNegotiableMOQ: 500 Pieces

-

304 Stainless Steel Double Ferrule Pipe Fittings for High-Pressure SystemsNegotiableMOQ: 500 Pieces

-

Double Ferrule Pipe Fittings With Leak-Proof Design for Chemical TransferNegotiableMOQ: 500 Pieces

-

Durable Stainless Steel Double Ferrule Fittings With 10-Year WarrantyNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Fittings for Food Processing EquipmentNegotiableMOQ: 500 Pieces

-

Corrosion-Resistant Double Ferrule Pipe Fittings for Marine EnvironmentsNegotiableMOQ: 500 Pieces

-

316L Stainless Steel Double Ferrule Fittings With Mill Test ReportNegotiableMOQ: 500 Pieces

-

Corrosion Resistant 316L SS Double Ferrule Valve, VCR and VCO Connections, High Vacuum RatedNegotiableMOQ: 100 Sets

-

304/316 Stainless Steel Double Ferrule Elbow for Instrumentation TubingNegotiableMOQ: 50 Pieces