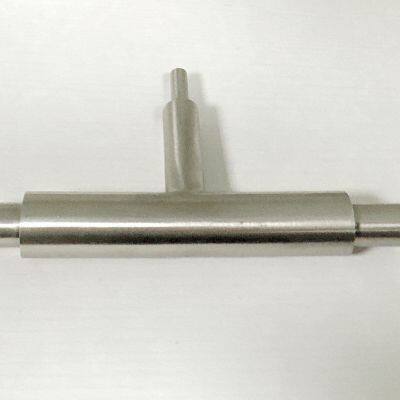

Sanitary Double Pipe Bends for Food/Biopharm Industries, Mirror Polished Ra≤0.8μm, 3A Certified

As a leading manufacturer based in Shanghai, Shanghai Quanbao Electronic Materials Technology Co., Ltd. specializes in precision-engineered sanitary components for critical industries. Our double pipe bends represent the pinnacle of hygienic fluid transfer solutions, combining rigorous 3A certification with exceptional surface quality to meet the exacting standards of food and pharmaceutical processing.

Engineered for contamination-free performance, these mirror-finished bends ensure product integrity while reducing maintenance downtime. The seamless internal surface (Ra≤0.8μm) prevents bacterial harborage, making them ideal for CIP/SIP systems where microbial control is paramount. With over 15 years of metallurgical expertise, our Shanghai facility employs advanced polishing technologies to deliver consistent, audit-ready compliance.

Core Technical Specifications:

| Parameter | Specification |

|---|---|

| Material Grades | 304SS / 316LSS (optional) |

| Angular Configuration | 45° or 90° standard bends |

| Radius Options | 1.5D, 2D, 3D centerline |

| Pressure Tolerance | 10 bar @ 120°C (standard) |

| End Connections | Clamp, weld, or threaded |

The double pipe configuration offers significant advantages over traditional single bends:

- Enhanced Flow Dynamics: Reduced turbulence and pressure drop compared to multiple single elbows

- Space Optimization: Compact design minimizes installation footprint in crowded processing areas

- Leak Prevention: Single-piece construction eliminates intermediate connection points

For applications requiring ultra-high purity – such as aseptic filling lines or cell culture media transfer – our electropolishing option achieves Ra≤0.4μm surface roughness. All products undergo rigorous dimensional verification and passivation treatment to ensure corrosion resistance in acidic or high-chloride environments.

Trusted by multinational dairy processors and biotech facilities, Shanghai Quanbao maintains full traceability from raw material to finished product. Our Shanghai-based quality center performs batch-specific documentation including:

- Material Certificates (MTC) per EN 10204 3.1

- Surface Roughness Test Reports

- 3A Sanitary Compliance Statements

With dedicated technical support for installation validation and custom angle requirements, we help streamline your sanitary system design. Contact our Shanghai engineering team today for project-specific solutions that optimize both performance and regulatory compliance.

Frequently Asked Questions:

Q1: What makes these bends suitable for biopharm applications?

A: The Ra≤0.8μm mirror finish exceeds ASME BPE standards for biofilm prevention, while 3A certification validates cleanability for parenteral drug manufacturing.

Q2: Can I get custom angles beyond 45°/90°?

A: Yes, we offer non-standard angles (15°-180°) with same material certifications. Lead times vary based on complexity.

Q3: Are gaskets included with clamp-end connections?

A: Gaskets are supplied separately to allow material selection (EPDM, FKM, PTFE) per your process media.

Q4: How do I verify surface roughness?

A: Each shipment includes test reports from calibrated profilometers. We can provide sample coupons for validation.

Q5: What's the maximum operating temperature?

A: Standard units withstand 150°C continuously. Higher temperatures require special heat treatment - consult our engineers.

Q6: Do you offer X-ray inspection for welds?

A: Full penetration welds undergo 100% visual and dye penetrant testing. Radiographic examination is available for critical applications.

Q7: Can I get FDA-compliant documentation?

A: All materials meet FDA 21 CFR 177.2600 for food contact. Declaration of Conformity is provided.

Q8: What's the lead time for DN50 (2") 316L bends?

A: Standard DN50 90° bends ship in 2-3 weeks. Electropolished versions add 5 business days.

Send Inquiry to This Supplier

You May Also Like

-

ASME BPE Compliant Double Ferrule Fittings for Pharmaceutical PipingNegotiableMOQ: 500 Pieces

-

304 Stainless Steel Double Ferrule Pipe Fittings for High-Pressure SystemsNegotiableMOQ: 500 Pieces

-

Double Ferrule Pipe Fittings With Leak-Proof Design for Chemical TransferNegotiableMOQ: 500 Pieces

-

Durable Stainless Steel Double Ferrule Fittings With 10-Year WarrantyNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Fittings for Food Processing EquipmentNegotiableMOQ: 500 Pieces

-

Corrosion-Resistant Double Ferrule Pipe Fittings for Marine EnvironmentsNegotiableMOQ: 500 Pieces

-

316L Stainless Steel Double Ferrule Fittings With Mill Test ReportNegotiableMOQ: 500 Pieces

-

Corrosion Resistant 316L SS Double Ferrule Valve, VCR and VCO Connections, High Vacuum RatedNegotiableMOQ: 100 Sets

-

304/316 Stainless Steel Double Ferrule Elbow for Instrumentation TubingNegotiableMOQ: 50 Pieces

-

1/4" to 1" NPT Threaded Double Ferrule Elbow With MTR CertificationNegotiableMOQ: 50 Pieces