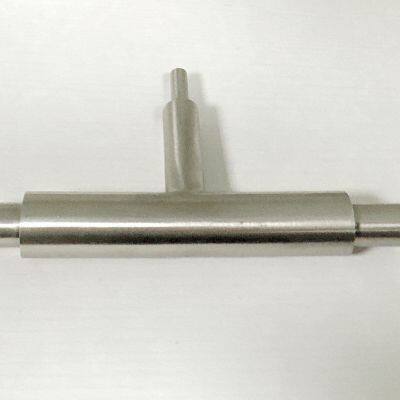

Stainless Steel Double Pipe Bends for Industrial Fluid Systems, Corrosion-Resistant 304/316L Material

Shanghai Quanbao Electronic Materials Technology Co., Ltd., a trusted supplier based in Shanghai, China, specializes in delivering high-performance Stainless Steel Double Pipe Bends engineered for demanding industrial environments. Our corrosion-resistant 304/316L stainless steel bends ensure reliable fluid transfer in critical systems while minimizing maintenance costs and downtime.

These precision-engineered components feature a dual-bend design that optimizes flow efficiency and installation flexibility. Ideal for chemical processing, oil/gas pipelines, and pharmaceutical applications, they provide exceptional longevity even when handling aggressive media or operating under extreme temperature fluctuations.

Key advantages include:

- Superior Durability: 304/316L SS construction resists pitting, crevice corrosion, and stress cracking.

- Flow Efficiency: Smooth internal radius reduces turbulence and pressure drop by up to 30% compared to sharp elbows.

- Custom Configurations: Available in multiple angles (45°/90°/180°) and dimensions to match existing infrastructure.

Technical Specifications:

| Parameter | Standard Range |

|---|---|

| Outer Diameter (OD) | 1/2" to 24" (Custom Sizes Available) |

| Wall Thickness | SCH 5S to SCH 80S |

| Bend Radius | 1.5D, 3D, 5D (D = Pipe Diameter) |

| Operating Pressure | Up to 1500 PSI (Varies by Configuration) |

The double-bend geometry allows complex directional changes within compact spaces, reducing joint counts and potential leak points. Each unit undergoes hydrostatic testing and visual inspection to guarantee structural integrity. For specialized requirements, we offer:

- Electropolished interiors for ultra-clean applications

- Bead blasted or mirror-finished exteriors

- Third-party material certification upon request

With over a decade of industrial solutions expertise, Shanghai Quanbao leverages advanced CNC bending technology and strict quality protocols to deliver components that meet ASTM A312/A403 standards. Our Shanghai-based manufacturing enables responsive order fulfillment for global clients, with technical support available throughout project lifecycle.

FAQ Section

Q1: What distinguishes 304 from 316L stainless steel for these bends?

A: While both offer excellent corrosion resistance, 316L contains molybdenum for enhanced protection against chlorides and acidic environments. We recommend 316L for marine or chemical processing applications.

Q2: Can you accommodate non-standard bend angles?

A: Yes, custom angles (e.g., 30°, 60°, 120°) can be manufactured based on technical drawings. Lead times may vary.

Q3: Are these compatible with high-temperature steam lines?

A: Absolutely. Both 304 and 316L maintain structural integrity at sustained temperatures up to 200°C (392°F), making them suitable for steam applications.

Q4: Do you provide documentation with shipments?

A: Standard deliveries include material test reports (MTRs). Additional certifications like NDT reports are available upon request.

Q5: How do I determine the optimal bend radius?

A: Larger radii (3D/5D) minimize flow resistance but require more space. Our engineers can advise based on your system’s pressure and layout constraints.

Q6: What packaging is used for international shipping?

A: Components are crated with anti-corrosion coatings and desiccant packs to prevent damage during transit. Export-grade wooden cases are standard.

Partner with Shanghai Quanbao for bends that combine precision manufacturing with robust material science. Contact our Shanghai team today for project-specific quotations or technical consultations – let us optimize your fluid systems for maximum reliability and efficiency.

Send Inquiry to This Supplier

You May Also Like

-

Double Ferrule Pipe Fittings With Leak-Proof Design for Chemical TransferNegotiableMOQ: 500 Pieces

-

Durable Stainless Steel Double Ferrule Fittings With 10-Year WarrantyNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Fittings for Food Processing EquipmentNegotiableMOQ: 500 Pieces

-

Corrosion-Resistant Double Ferrule Pipe Fittings for Marine EnvironmentsNegotiableMOQ: 500 Pieces

-

316L Stainless Steel Double Ferrule Fittings With Mill Test ReportNegotiableMOQ: 500 Pieces

-

Corrosion Resistant 316L SS Double Ferrule Valve, VCR and VCO Connections, High Vacuum RatedNegotiableMOQ: 100 Sets

-

304/316 Stainless Steel Double Ferrule Elbow for Instrumentation TubingNegotiableMOQ: 50 Pieces

-

1/4" to 1" NPT Threaded Double Ferrule Elbow With MTR CertificationNegotiableMOQ: 50 Pieces

-

Precision Machined 316L Stainless Steel Double Ferrule Elbow FittingNegotiableMOQ: 50 Pieces

-

ASTM A270 Compliant Sanitary Double Ferrule Elbow for PharmaNegotiableMOQ: 50 Pieces