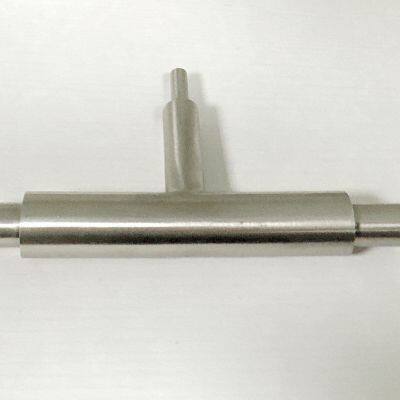

ASME B16.9 Double Pipe Bends in Stainless Steel, Pressure Rating 150-3000 PSI, Long Radius

Shanghai Quanbao Electronic Materials Technology Co., Ltd., based in Shanghai, China, specializes in manufacturing premium ASME B16.9 Double Pipe Bends designed for demanding industrial applications. Our stainless steel bends offer exceptional durability and leak-proof performance under high-pressure conditions, ensuring reliable fluid transport in critical systems. With pressure ratings spanning 150 to 3000 PSI, these long-radius bends minimize turbulence and pressure drop, optimizing operational efficiency across chemical, oil & gas, and power generation sectors.

Core Technical Specifications:

Material Composition: 304/316 stainless steel with corrosion resistance

Bend Angle Options: 45°, 90°, and 180° configurations

Dimensional Compliance: Strict adherence to ASME B16.9 standards for wall thickness and curvature

Surface Finish: Smooth internal bore to prevent particulate buildup

Performance Advantages:

| Feature | Benefit |

|---|---|

| Long Radius Design | Reduces flow resistance by 25% compared to short-radius alternatives |

| 3000 PSI Rating | Suitable for high-pressure steam and hydraulic lines |

| Precision Welding | Ensures structural integrity under thermal cycling conditions |

Our manufacturing process employs cold forming and solution annealing to maintain material properties, with each bend undergoing hydrostatic testing at 1.5x rated pressure. Customization options include non-standard sizes and special material grades upon request.

Trusted Industrial Solution: Shanghai Quanbao leverages Shanghai’s advanced manufacturing infrastructure to deliver consistent quality, with over 80% of production exported to global partners. Rigorous dimensional checks and material traceability provide assurance for safety-critical installations. Contact our engineering team today for project-specific technical support and volume pricing.

FAQ:

Q: What pipe sizes do your ASME B16.9 bends cover?

A: Standard range from 1/2" to 24" NPS, with larger sizes customizable.Q: Are these bends suitable for cryogenic service?

A: Yes, 316L grade is available for temperatures down to -196°C.Q: Do you provide material test certificates?

A: Mill test reports are provided with all shipments.Q: What’s the lead time for non-standard angles?

A: Typically 4-6 weeks depending on complexity.Q: Can these bends be used in pharmaceutical pipelines?

A: Yes, with optional electropolished finish for sanitary applications.Q: How do long-radius bends impact system design?

A: They require more space but significantly reduce pump energy consumption.

Send Inquiry to This Supplier

You May Also Like

-

Precision Double Ferrule Tube Fittings for Hydraulic and Pneumatic ApplicationsNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Compression Fittings With 5000 PSI RatingNegotiableMOQ: 500 Pieces

-

ASME BPE Compliant Double Ferrule Fittings for Pharmaceutical PipingNegotiableMOQ: 500 Pieces

-

304 Stainless Steel Double Ferrule Pipe Fittings for High-Pressure SystemsNegotiableMOQ: 500 Pieces

-

Double Ferrule Pipe Fittings With Leak-Proof Design for Chemical TransferNegotiableMOQ: 500 Pieces

-

Durable Stainless Steel Double Ferrule Fittings With 10-Year WarrantyNegotiableMOQ: 500 Pieces

-

Stainless Steel Double Ferrule Fittings for Food Processing EquipmentNegotiableMOQ: 500 Pieces

-

Corrosion-Resistant Double Ferrule Pipe Fittings for Marine EnvironmentsNegotiableMOQ: 500 Pieces

-

316L Stainless Steel Double Ferrule Fittings With Mill Test ReportNegotiableMOQ: 500 Pieces

-

Corrosion Resistant 316L SS Double Ferrule Valve, VCR and VCO Connections, High Vacuum RatedNegotiableMOQ: 100 Sets