Alloy Saw Blade Resharpening, Available for Nationwide Delivery

Aoxiang Professional Saw Blade Grinding Service - Restore Sharpness to Every Saw Blade

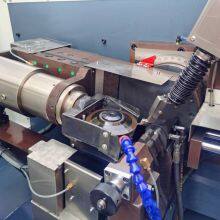

Using the high - end AX900 - B3 automatic gear grinding machine, we provide you with accurate, efficient and reliable saw blade grinding solutions.

Accuracy Guaranteed, Cutting Like New:The AX900 - B3 fully automatic CNC gear grinding machine with imported technology ensures that the grinding angle of each tooth is precisely the same, restoring the saw blade's factory performance.

Cost Saving, Reducing Costs and Increasing Efficiency:The cost of professional grinding is only 20% - 30% of that of a new saw blade, effectively extending the service life of the saw blade and directly reducing your production consumable costs.

Stable Quality, Improving the Yield:The precise cutting edge ensures a smooth and burr - free cutting section, reducing subsequent processes and improving the processing quality of your final products.

Fast Turnaround, Ensuring Non - stop Production:With a standard process, we promise to complete the grinding within 3 working days and provide an express service to minimize your downtime waiting.

Types of Saw Blades We Are Good at Grinding

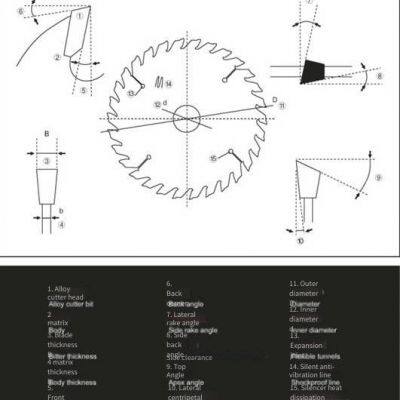

We specialize in the grinding of various carbide circular saw blades, including but not limited to: Applicable materials: Woodworking Saw Blades, Aluminum Saw Blades, Plate Saw Blades, Plastic Saw Blades

, etc.Tooth profile range: Alternating teeth, trapezoidal teeth, left and right teeth, composite teeth, etc. Diameter range: Ø80mm - Ø2200mm (covering most industrial application scenarios).

Our saw blade sharpening service process

We promise a clear and fully controllable process: Receiving and inspection. After receiving the saw blade, we will immediately conduct number registration and perform a preliminary inspection and communication on the saw blade's baseline wear, missing teeth, fallen teeth, etc. Plan and quotation. Based on the inspection results and your processing requirements, we will provide a specific sharpening plan and a transparent quotation. After your confirmation, we will start the work. Precision sharpening. Use the AX900-B3 fully automatic gear grinding machine (select the appropriate equipment according to the diameter). Conduct standardized operations, including angle calibration, precision grinding and other steps. Final inspection and cleaning. Conduct a 100% on-machine inspection of the sharpened saw blade to ensure that parameters such as angle and radial runout are qualified, and then clean and package it. Intact delivery. Properly package the saw blade sharpened as good as new, attach the inspection report, and deliver it to your hands in the agreed way.

Service pricing standards

Adopt a transparent pricing model:

Pricing by diameter and number of teeth: Fair, reasonable, clear and easy to understand.

Free initial inspection: We will inspect and evaluate your saw blade free of charge.

Bulk discount: For long - term cooperation or bulk sharpening, enjoy a more competitive price.

> > Welcome to send saw blade pictures or physical objects to get an instant quote!

<

Equipment advantage: We are equipment manufacturers, and our equipment is produced for manufacturing high-end saw blades. The AX900-B3 machine tool ensures a high standard of sharpening process.

Technical advantage: We have an experienced professional technical team that deeply understands the application requirements of different saw blades on different materials.

Quality commitment: We have established a complete quality traceability system to ensure that every saw blade handled by us meets the promised standards.

If you are not satisfied with the sharpening quality, we promise to rework it for free.

Act now and start your journey of cost reduction and efficiency improvement!

Online inquiry: Just provide the diameter, number of teeth, and a photo of the tooth profile of the saw blade, and you can quickly get a quote.

Service hotline: 13425671988, Mr. Yan

Service address: No. 61, Industrial Avenue, Baini Town, Sanshui District, Foshan City.

Send Inquiry to This Supplier

You May Also Like

-

Aoxiang Alloy Circular Saw Blade Grinder, Fully Automatic Cnc Grinder, Hard Saw Blade Tooth Grinding MachineUS$ 8153.85 - 8923.08MOQ: 1 Unit

-

Factory Direct Sales - Saw Blade Tooth Grinding Machine, Fully Automatic Carbide Saw Blade Tooth Grinding MachineUS$ 10000 - 10461.54MOQ: 1 Unit

-

Foshan Aoxiang Gear Grinding Machine Manufacturer Direct Sales Saw Blade Gear Grinding MachineUS$ 10000 - 10461.54MOQ: 1 Unit

-

Factory Direct Sale Alloy Saw Blade Tooth Grinding Machine, High Quality and Affordable, Fully Automatic Front and Rear Angle Saw Blade Tooth Grinding MachineUS$ 10000 - 10461.54MOQ: 1 Unit

-

Factory Direct Sale: Aoxiang Alloy Saw Blade Tooth Grinding MachineUS$ 8923.08 - 9692.31MOQ: 1 Unit

-

Factory Direct Sale Alloy Saw Blade Tooth Grinding Machine, Aoxiang Tooth Grinding Machine, Machine for Grinding Carbide Saw BladesUS$ 10000 - 10461.54MOQ: 1 Unit

-

Fully Automatic Cnc Alloy Circular Saw Blade Tooth Grinding MachineUS$ 8923.08 - 9692.31MOQ: 1 Unit

-

Factory Direct Sale Alloy Saw Blade Front and Rear Angle Gear Grinding Machine - Aoxiang MachineryUS$ 8153.85 - 8923.08MOQ: 1 Unit

-

Aoxiang Factory Direct Sale Automatic Alloy Saw Blade Tooth Grinding Machine Ax900 - B2, Cnc TypeUS$ 8923.08 - 9692.31MOQ: 1 Unit

-

Aoxiang Factory Direct Sale Fully Automatic Alloy Circular Saw Blade GrinderUS$ 10000 - 10461.54MOQ: 1 Unit