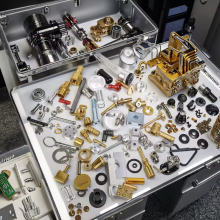

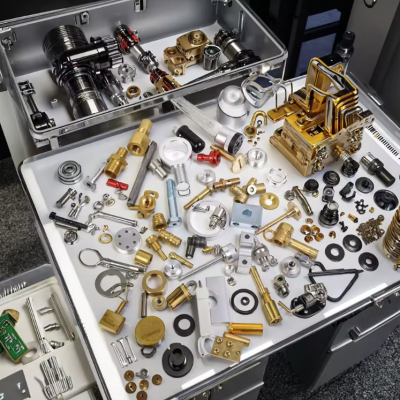

Industrial-Grade CNC Aluminum Alloy Milling Parts Compatible With CNC Machining Centers and Tools

Discover high-precision industrial-grade CNC aluminum alloy milling parts from Ningbo Changfeng Mechanical Factory, a trusted manufacturer since 1990. These parts are engineered for seamless compatibility with CNC machining centers and tools, ensuring reliable performance in demanding industrial applications. With over three decades of expertise and a global export reach spanning North America, Europe, Asia, and beyond, our products deliver exceptional durability and efficiency. Ideal for enhancing manufacturing processes, they reduce downtime and boost productivity. Experience the advantage of precision-crafted components that meet rigorous industrial standards.

Our CNC aluminum alloy milling parts feature advanced design elements tailored for industrial use. Key characteristics include:

- Superior Material Quality: Made from high-grade aluminum alloy, these parts offer excellent strength-to-weight ratio, corrosion resistance, and thermal stability, making them suitable for heavy-duty operations.

- Enhanced Compatibility: Designed to integrate smoothly with a wide range of CNC machining centers and tools, minimizing setup time and ensuring versatile application across industries like automotive, aerospace, and electronics.

- Precision Engineering: Achieved through state-of-the-art CNC technology, resulting in tight tolerances and smooth surface finishes that reduce wear and extend component lifespan.

- Customization Options: Dimensions, colors, and specific configurations are customizable upon request, allowing for tailored solutions that fit unique project requirements.

Technical specifications highlight the robustness of these milling parts. Below is a summary of key parameters:

| Attribute | Details |

| Material Composition | Aluminum Alloy (e.g., 6061 or 7075 variants) |

| Standard Dimensions | Variable, customizable based on application |

| Tolerance Range | High precision, typically ±0.005 mm |

| Surface Finish | Smooth, anodized or milled finishes |

| Operating Temperature | -20°C to 150°C, suitable for industrial environments |

Advantages for clients include reduced operational costs through minimal maintenance, improved machining accuracy that enhances product quality, and flexibility in customization to meet specific production needs. For instance, the lightweight nature of aluminum alloy allows for faster machining speeds, while the industrial-grade build ensures longevity even in high-stress settings. This translates to tangible benefits like lower total cost of ownership and increased output efficiency.

Invest in Ningbo Changfeng's CNC aluminum alloy milling parts to elevate your manufacturing capabilities with reliable, high-performance components. Backed by extensive experience and a commitment to quality, we offer solutions that drive operational excellence. Contact us today for personalized quotes or to discuss your project requirements—our team is ready to support your success with timely deliveries and expert advice. Don't miss the opportunity to optimize your CNC operations with parts that deliver consistent results.

Frequently Asked Questions (FAQ)

-

Q: What materials are used in these milling parts?

A: They are crafted from high-quality aluminum alloy, known for its durability and lightweight properties, ideal for industrial applications. -

Q: Are these parts compatible with all CNC machines?

A: Yes, they are designed for broad compatibility with CNC machining centers and tools; specific models can be confirmed upon inquiry. -

Q: Can I request custom sizes or configurations?

A: Absolutely, dimensions and features are customizable upon request to suit your unique operational needs. -

Q: What is the typical lead time for orders?

A: Lead times vary based on order volume and customization; standard batches may ship within 2-4 weeks. -

Q: How do these parts enhance manufacturing efficiency?

A: Their precision engineering reduces machining errors and downtime, leading to higher productivity and cost savings. -

Q: Are there options for surface treatments?

A: Yes, various finishes like anodizing are available to improve corrosion resistance and aesthetics. -

Q: What industries commonly use these parts?

A: They are widely applied in sectors such as automotive, aerospace, electronics, and general industrial machinery.

Send Inquiry to This Supplier

You May Also Like

-

Durable CNC Aluminum Alloy Milling Parts With Anodized Finish for Electronics and Robotics EnclosuresUS$ 12MOQ: 10 Units

-

Aerospace Industry CNC Aluminum Alloy Milling Parts With AS9100 Certification for Aircraft ComponentsUS$ 12MOQ: 10 Units

-

High-Strength CNC Aluminum Alloy Milling Parts Featuring Corrosion Resistance for Marine UseUS$ 12MOQ: 10 Units

-

Precision CNC Aluminum Alloy Milling Parts With ±0.01mm Tolerance for Custom Industrial ApplicationsUS$ 12MOQ: 10 Units

-

OEM/ODM Customized Grey Iron Casting Parts Carbon Steel Lost Wax Casting for Mining Machinery 304 Stainless Steel Casting PartUS$ 5MOQ: 10 Pieces

-

OEM Precision Investment Casting Services Stainless Steel 304 316 Lost Wax Investment Casting ISO9001 Certified ManufacturingUS$ 15MOQ: 10 Pieces

-

OEM Foundry Investment Lost Wax Casting Low-Carbon Alloy Steel CNC Machining Precision Casting ServicesUS$ 15MOQ: 10 Pieces

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units