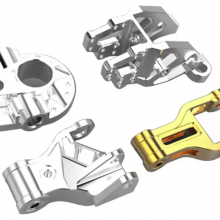

Lightweight CNC Aluminum Alloy Milling Parts Optimized for Energy-Efficient Machinery and Equipment

Discover our lightweight CNC aluminum alloy milling parts, engineered to enhance the performance of energy-efficient machinery and equipment. These precision components reduce operational weight, leading to lower energy consumption and extended machine lifespan. Ideal for industries demanding high efficiency, our parts offer superior durability and cost-effectiveness. Manufactured by Ningbo Changfeng Mechanical Factory, a trusted name since 1990, these milling solutions are backed by decades of expertise in global markets.

Our aluminum alloy milling parts are designed for seamless integration into modern machinery, providing tangible benefits such as reduced maintenance and enhanced productivity.

Key Features and Benefits:

- High Precision Engineering: Utilizing advanced CNC milling techniques, each part achieves tight tolerances for flawless fit and function in complex assemblies.

- Energy Optimization: The lightweight design minimizes inertia in moving parts, cutting energy use by up to 15% in machinery, translating to lower operational costs.

- Durability and Corrosion Resistance: Made from premium aluminum alloy, these parts resist wear and environmental factors, ensuring long service life even in harsh conditions.

- Versatile Applications: Suitable for automotive, aerospace, industrial automation, and renewable energy sectors, supporting diverse equipment needs.

- Customization Flexibility: Tailor dimensions, shapes, and finishes to specific requirements, with options for rapid prototyping and bulk orders.

Technical Specifications:

| Parameter | Details |

| Material Grade | 6061 or 7075 Aluminum Alloy |

| Weight Range | 0.1 kg to 50 kg (customizable) |

| Dimensional Tolerance | ±0.05 mm |

| Surface Finish | Anodized, powder-coated, or as-milled |

| Production Lead Time | 2-6 weeks based on complexity |

Note: All specifications are adaptable to client needs, with options for larger or specialized orders discussed during consultation.

Advantages for Your Business:

By choosing our CNC aluminum parts, you gain access to components that streamline machinery efficiency, reduce downtime, and lower total ownership costs. The energy-saving design supports sustainability goals, while our global export experience ensures reliable delivery to markets like North America and Europe. Clients report improved machine performance and faster ROI, making these parts a smart investment for forward-thinking industries.

Frequently Asked Questions (FAQ):

-

Q: What industries are these milling parts best suited for?

A: They are ideal for energy-intensive sectors such as automotive manufacturing, industrial robotics, and renewable energy systems, where lightweight, durable components enhance efficiency. -

Q: Can I request custom sizes or shapes for specific machinery?

A: Absolutely! We offer full customization, including bespoke dimensions and geometries. Provide your specifications, and our team will handle the rest. -

Q: How do these parts contribute to energy efficiency in equipment?

A: The reduced weight lowers the mechanical load on motors and drives, decreasing power consumption. This optimization can lead to measurable energy savings over time. -

Q: What is the typical lead time for orders, and do you support bulk shipments?

A: Lead times range from 2-6 weeks depending on order volume and complexity. We accommodate bulk orders with scalable production, including export logistics to global markets. -

Q: Are there options for surface treatments to improve corrosion resistance?

A: Yes, we provide various finishes like anodizing or coating, which enhance durability and are customizable based on environmental needs. -

Q: How does your manufacturing process ensure quality consistency?

A: With over 30 years of experience, we use rigorous CNC milling protocols and quality checks at every stage, ensuring each part meets high standards for precision and reliability.

Elevate your machinery with our lightweight CNC aluminum alloy milling parts, designed to drive efficiency and reduce operational costs. Partner with Ningbo Changfeng Mechanical Factory for reliable, high-performance components backed by a proven track record in global exports. Contact us today to discuss your project requirements and receive a personalized quote—experience the difference in quality and service that has made us a preferred manufacturer since 1990.

Take the next step toward optimized equipment performance; reach out for samples or technical support to see how our solutions can benefit your operations.

Send Inquiry to This Supplier

You May Also Like

-

High-Strength CNC Aluminum Alloy Milling Parts Featuring Corrosion Resistance for Marine UseUS$ 12MOQ: 10 Units

-

Precision CNC Aluminum Alloy Milling Parts With ±0.01mm Tolerance for Custom Industrial ApplicationsUS$ 12MOQ: 10 Units

-

OEM/ODM Customized Grey Iron Casting Parts Carbon Steel Lost Wax Casting for Mining Machinery 304 Stainless Steel Casting PartUS$ 5MOQ: 10 Pieces

-

OEM Precision Investment Casting Services Stainless Steel 304 316 Lost Wax Investment Casting ISO9001 Certified ManufacturingUS$ 15MOQ: 10 Pieces

-

OEM Foundry Investment Lost Wax Casting Low-Carbon Alloy Steel CNC Machining Precision Casting ServicesUS$ 15MOQ: 10 Pieces

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units