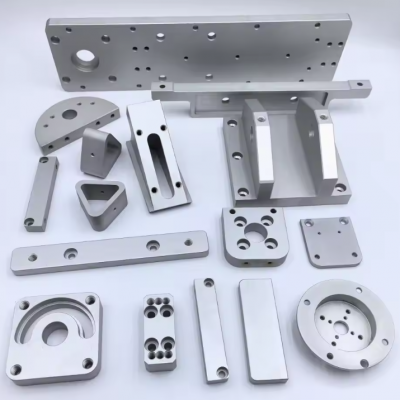

Small-Scale CNC Machining Precision Metal Parts With Tight Tolerances for Robotics

Ningbo Changfeng Mechanical Factory specializes in delivering high-precision small-scale CNC machining services for robotics applications, ensuring metal parts with exceptionally tight tolerances to enhance robotic system performance. With decades of experience since 1990, our solutions cater to global markets, offering reliable, custom-engineered components that minimize operational failures and maximize efficiency. Ideal for robotics innovators, these parts are designed for seamless integration, reducing downtime and improving overall automation outcomes. Trust our expertise to provide cost-effective, scalable production that meets the demanding needs of modern robotics.

Our CNC machining capabilities focus on precision and adaptability, making them perfect for robotics applications where accuracy is non-negotiable. Key features include:

- Advanced CNC Technology: Utilizing state-of-the-art CNC machines to achieve consistent, high-quality results with minimal human error.

- Custom Material Options: Available in a range of metals such as aluminum, stainless steel, and brass, selected for durability and lightweight properties.

- Superior Precision: Capable of maintaining tight tolerances down to ±0.005mm, critical for robotics parts like gears and actuators to ensure smooth motion and reduced wear.

- Scalable Production: Designed for small to medium batches, allowing flexibility for prototyping or volume runs without compromising quality.

- Robust Quality Assurance: Incorporating rigorous inspection at every stage, from design to final output, to guarantee defect-free components.

Technical specifications are detailed below to help you understand the core parameters. For instance, our tolerance levels and material choices directly impact robotic efficiency and longevity:

| Parameter | Value | Benefit to Robotics |

|---|---|---|

| Tolerance Range | ±0.005mm | Ensures precise alignment for robotic arms, reducing vibration and energy loss |

| Material Options | Aluminum, Steel, Brass | Provides strength and lightweight properties for faster, more efficient movements |

| Size Capabilities | Customizable from 5mm to 500mm | Allows tailored fits for various robotic components, enhancing modularity |

| Lead Time | 2-4 weeks (standard) | Supports quick iterations in robotics development, speeding time-to-market |

The advantages of our precision metal parts extend beyond technical specs to tangible client benefits. For robotics manufacturers, this translates to:

- Enhanced Durability: Parts withstand high-stress environments, lowering replacement costs and extending robotic lifespan.

- Improved Efficiency: Tight tolerances reduce friction and energy consumption, boosting overall system output.

- Cost Savings: Small-scale production minimizes waste and inventory, while flexible MOQs accommodate budget constraints.

- Customization Support: Our team offers design assistance to optimize parts for specific robotic applications, ensuring seamless integration.

Elevate your robotics projects with Ningbo Changfeng's reliable CNC machining solutions—experience the difference of precision engineering backed by over 30 years of industry expertise. Contact us today for a customized quote or to discuss how our parts can enhance your automation systems. With a strong presence in markets like North America and Europe, we're committed to delivering excellence and building long-term partnerships.

Frequently Asked Questions (FAQ)

Q: What materials are commonly used for these precision parts?

A: We typically work with metals like aluminum, steel, and brass, which are customizable based on your robotics requirements for strength and weight.

Q: How tight can the tolerances be achieved?

A: Our CNC machining can achieve tolerances as tight as ±0.005mm, ensuring high accuracy for critical robotic components.

Q: What is the minimum order quantity for small-scale production?

A: MOQ is flexible and can be tailored to your needs, often starting from low volumes for prototyping or testing.

Q: How long does production take?

A: Standard lead times range from 2 to 4 weeks, but this can be adjusted based on project complexity and order size.

Q: Can you handle custom designs for specific robotics applications?

A: Yes, we offer full design support and engineering assistance to create parts that fit your unique robotic systems perfectly.

Q: Are certifications available for quality assurance?

A: Certifications are available upon request, and we adhere to strict quality control processes to ensure reliability.

Q: What industries besides robotics do you serve?

A: Our parts are also suitable for automation, aerospace, and industrial machinery, with applications customizable to various sectors.

Q: How do you ensure consistency in tight tolerance machining?

A: Through advanced CNC equipment and multi-stage inspections, we maintain uniformity across all batches to meet exact specifications.

Send Inquiry to This Supplier

You May Also Like

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units

-

CNC Milling Parts Stainless Steel/Aluminum Alloy Compatible With CNC Machines for High-Accuracy Industrial FabricationUS$ 14MOQ: 10 Units

-

Precision CNC Milling Parts Aluminum/Steel/Brass in Various Sizes for Industrial Applications & Machinery FabricationUS$ 14MOQ: 10 Units

-

Versatile CNC Milling Parts Stainless Steel/Brass/Alloy Steel Suitable for Heavy-Duty Industrial & Manufacturing UseUS$ 14MOQ: 10 Units

-

CNC Milling Parts Aluminum/Carbon Steel With Quick Turnaround Times for Engineering Prototypes & Custom FabricationUS$ 14MOQ: 10 Units

-

CNC Milling Parts Medical-Grade Stainless Steel/Aluminum Designed for Medical Device Production and InstrumentationUS$ 14MOQ: 10 Units