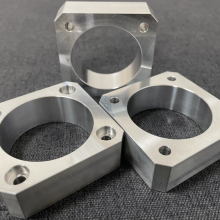

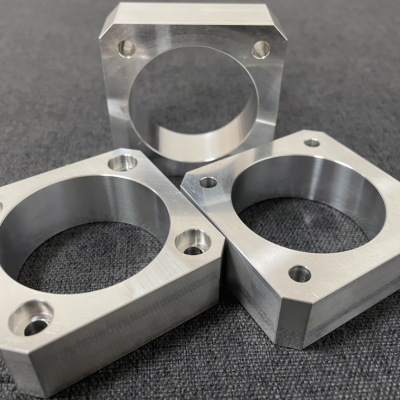

CNC Aluminum Alloy Milling Parts for Medical Devices Including Surgical Instruments and Implants

Our CNC aluminum alloy milling parts are engineered for precision and reliability in critical medical applications, including surgical instruments and implants. Manufactured by Ningbo Changfeng Mechanical Factory, a trusted name since 1990, these components ensure high performance and safety in demanding healthcare environments. With extensive experience in global exports to markets like North America and Europe, we deliver tailored solutions that meet stringent industry requirements. These parts offer exceptional durability and corrosion resistance, making them ideal for life-saving medical devices. Choose our products for consistent quality and expert craftsmanship that supports your medical innovations.

Key features and benefits include:

High Precision Machining: Utilizing advanced CNC technology, our parts achieve tight tolerances (e.g., ±0.01mm) for flawless fit and function in medical assemblies.

Superior Material Properties: Made from aluminum alloy, these components are lightweight, non-toxic, and resistant to corrosion, ensuring long-term reliability in sterile environments.

Customization Options: Available in various sizes, colors, and surface finishes like anodized or polished, allowing for bespoke designs that match specific device requirements.

Enhanced Safety: Designed for easy sterilization and reduced risk of contamination, supporting infection control in surgical settings.

Cost Efficiency: Optimized production processes minimize waste and lead times, providing cost-effective solutions without compromising quality.

Technical specifications are outlined in the table below, showcasing core parameters for common applications. Note that all values are customizable based on client needs.

| Attribute | Typical Value | Notes |

| Material Grade | 6061 or 7075 Aluminum | High strength-to-weight ratio |

| Tolerance Range | ±0.01mm to ±0.05mm | Adjustable for precision needs |

| Surface Finish | Anodized, Polished | Enhances durability and aesthetics |

| Application Examples | Surgical tools, Implants | Suitable for FDA-compliant devices |

Clients benefit from our global expertise, with exports to over 15 regions including North America and Europe, ensuring timely delivery and responsive support. The CNC milling process allows for complex geometries, reducing assembly time and improving device efficiency. For instance, our parts contribute to lighter, more ergonomic surgical instruments, enhancing user comfort and patient outcomes. Additionally, customization options mean you can adapt designs for specific implants, minimizing revision surgeries and healthcare costs.

Invest in our CNC aluminum alloy milling parts to elevate your medical device performance with dependable, precision-engineered components. Backed by decades of manufacturing excellence, we offer scalable solutions that align with your production goals. Contact Ningbo Changfeng today for a consultation on custom orders—our team is ready to provide samples and quotes to meet your unique requirements. Partner with us for reliable supply chain support and innovative machining that drives success in the competitive medical market.

Frequently Asked Questions (FAQ)

Q: What materials are used in these CNC milling parts?

A: We use high-grade aluminum alloys, such as 6061 or 7075, known for their strength, lightweight properties, and corrosion resistance, ideal for medical applications.Q: Can I request custom sizes and designs for surgical instruments?

A: Yes, customization is available upon request. We work closely with clients to develop tailored dimensions, shapes, and features to fit specific device needs.Q: What industries do your products primarily serve?

A: Our parts are designed for medical devices, including surgical instruments, implants, and diagnostic equipment, ensuring compatibility with healthcare standards.Q: Are there certifications for medical use?

A: Certifications can be discussed based on customer requirements; we adhere to industry best practices and can provide documentation upon request.Q: What is the typical lead time for orders?

A: Lead times vary but are generally 4-6 weeks for standard orders; expedited options are available for urgent projects.Q: How do I place an order or request a quote?

A: Contact us via email or our website with your specifications; we'll provide a detailed quote and guide you through the ordering process.Q: Do you ship internationally to markets like Europe or Asia?

A: Yes, we export globally to regions including North America, Europe, and Asia, with logistics support for seamless delivery.

Send Inquiry to This Supplier

You May Also Like

-

OEM Precision Investment Casting Services Stainless Steel 304 316 Lost Wax Investment Casting ISO9001 Certified ManufacturingUS$ 15MOQ: 10 Pieces

-

OEM Foundry Investment Lost Wax Casting Low-Carbon Alloy Steel CNC Machining Precision Casting ServicesUS$ 15MOQ: 10 Pieces

-

Hot Selling CNC Milling Turning Customized Metal CNC Machining Services Non-standard Parts Turning Milling Composite ProcessingUS$ 10MOQ: 10 Units

-

High Grade Wholesale CNC Machining Precision Metal Parts Oem Odm Customized Aluminum Alloy Milling PartsUS$ 11MOQ: 10 Units

-

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 Units

-

Advanced OEM CNC Machining Service for Stainless Steel Aluminum Brass Bronze & Copper Parts Including BroachingUS$ 13MOQ: 10 Units

-

High Precision CNC Lathe Turning Milling Machining Parts Custom Quality Aluminum Stainless Steel Brass Fabrication CNC ServicesUS$ 14MOQ: 10 Units

-

CNC Stainless Steel Cooling Plate 3D Printing Gear Ball Copper Screw Stamping Anodized Aluminum Ring Parts Cnc Machining ServiceUS$ 15MOQ: 10 Units

-

CNC Milling Parts Stainless Steel/Aluminum Alloy Compatible With CNC Machines for High-Accuracy Industrial FabricationUS$ 14MOQ: 10 Units

-

Precision CNC Milling Parts Aluminum/Steel/Brass in Various Sizes for Industrial Applications & Machinery FabricationUS$ 14MOQ: 10 Units