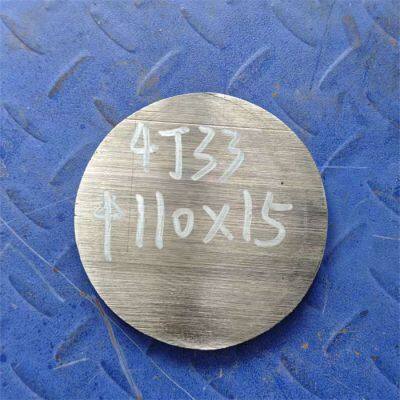

Iron-Nickel Alloy Bar 4J33 in Various Sizes and Diameters for Custom Industrial Applications

Jiangsu Zhonggongte Metallurgical Technology presents premium Iron-Nickel Alloy Bar 4J33, engineered for precision industrial applications requiring exceptional thermal stability. Our controlled-expansion alloy bars deliver unmatched dimensional consistency across temperature variations, making them ideal for sensitive instrumentation and high-tech manufacturing.

Manufactured under strict ISO9001 quality standards, these bars offer customizable dimensions to fit specialized engineering requirements. With global export capabilities through multiple Chinese ports, we ensure reliable supply chains for North American, European, and Asian industrial markets.

Technical Specifications & Performance Advantages

Material Composition: Iron-Nickel alloy with controlled cobalt content ensuring consistent thermal expansion properties

Thermal Stability: Near-zero thermal expansion coefficient between -60°C to +80°C

Mechanical Properties: Tensile strength 520-650 MPa with excellent machinability characteristics

Surface Finish: Standard polished surface (Ra ≤ 0.8μm) with optional grinding services

| Diameter (mm) | Standard Lengths | Tolerance |

|---|---|---|

| 5-20 | 1000-3000mm | ±0.05mm |

| 21-50 | 500-6000mm | ±0.08mm |

| 51-200 | Custom | ±0.1mm |

Critical applications benefit from 4J33's unique properties:

Hermetic seals in electronic packaging maintain integrity during thermal cycling

Precision optical mounts preserve alignment in temperature-varying environments

Laser components requiring dimensional stability under operational heat loads

Why Choose Our Alloy Solutions

Our manufacturing expertise ensures bars with homogeneous microstructure and consistent mechanical properties throughout the material cross-section. Custom diameter options eliminate unnecessary machining waste, while our quality control protocols include:

Batch-specific thermal expansion coefficient verification

Ultrasonic testing for internal integrity

Full traceability from raw material to finished product

Partner with our metallurgical specialists to develop application-specific solutions. With established logistics networks to 30+ countries and annual export volume exceeding $100M, we deliver technical alloys with reliability you can depend on.

Request custom quotations for project-specific dimensions, or consult our technical team about post-processing services including precision turning, milling, and surface treatment options.

Frequently Asked Questions

Q: What's the thermal expansion coefficient of 4J33 alloy?

A: Typically 6.5×10⁻⁶/°C between 20-400°C, significantly lower than standard steels.

Q: Can you supply bars outside standard diameter ranges?

A: Yes, we accommodate custom diameter requests from 3mm to 250mm through specialized processing.

Q: What certifications accompany shipments?

A: All shipments include material test reports and ISO9001 compliance documentation.

Q: Do you provide machining services for finished components?

A: Secondary processing like CNC turning and milling are available upon request.

Q: What packaging prevents damage during transit?

A: We use moisture-resistant wrapping with wooden crate reinforcement for international shipments.

Q: How does 4J33 compare to Invar alloys?

A: 4J33 offers similar thermal properties with enhanced machinability and cost efficiency.

Q: What's the lead time for custom diameters?

A: Standard production requires 15-25 business days depending on quantity and specifications.

Q: Can you supply smaller quantities for prototyping?

A: Yes, we accommodate R&D and prototype orders with minimum quantity requirements.

Send Inquiry to This Supplier

You May Also Like

-

High-Performance Iron-Nickel Alloy Bar With Controlled Thermal Expansion for Precision EngineeringNegotiableMOQ: 50 Kilograms

-

Durable Iron-Nickel Alloy Bar 4J33 With Low Thermal Expansion and Corrosion Resistance PropertiesNegotiableMOQ: 50 Kilograms

-

High-Performance Iron-Nickel Alloy Bar 4J33 for Precision Instrument and Medical Device ComponentsNegotiableMOQ: 50 Kilograms

-

Precision Machinable Iron Nickel Alloy Bar for Cryogenic and Aerospace ApplicationsNegotiableMOQ: 50 Kilograms

-

Compatible Iron-Nickel Alloy Bar 4J33 for High-Temperature Environments and Fabrication ProcessesNegotiableMOQ: 50 Kilograms

-

Industrial Pure Titanium Plate Ta2 With Excellent Formability and Weldability for Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

Precision Titanium Alloy Bar TA15 in Various Diameters (5mm-200mm) for Industrial MachiningNegotiableMOQ: 50 Kilograms

-

Custom Precision Titanium Alloy Bar Stellite6 Factory Marine Corrosion Resistant Titanium Rod SupplierNegotiableMOQ: 50 Kilograms

-

High-Strength Titanium Alloy Bar Stellite12 With Superior Corrosion Resistance for Demanding EnvironmentsNegotiableMOQ: 50 Kilograms

-

Aerospace Application Titanium Alloy Bar for Landing Gear and Structural Components Using TA18NegotiableMOQ: 50 Kilograms