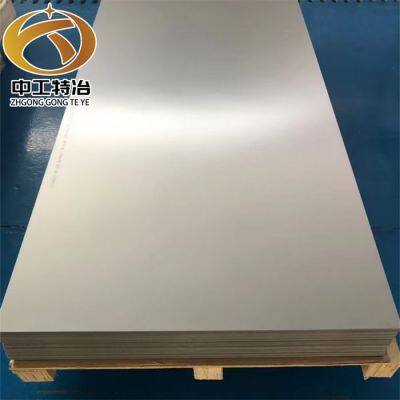

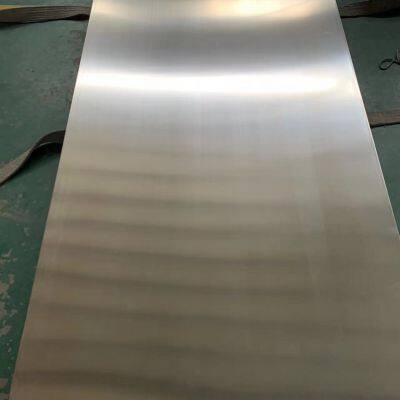

Industrial Grade Iron Nickel Alloy Plate for Cryogenic and High-Temperature Environments

Engineered for exceptional performance in extreme thermal conditions, our industrial-grade iron-nickel alloy plates deliver unmatched reliability in both cryogenic and high-temperature environments. These specialized metal plates maintain structural integrity across a remarkable temperature spectrum from -200°C to 1000°C, providing critical thermal stability where conventional materials fail. Manufactured under strict quality control protocols, these alloy plates feature superior thermal expansion characteristics and enhanced mechanical durability that make them indispensable for demanding industrial applications.

Through advanced metallurgical processing, we achieve precise control over material properties to ensure consistent performance in mission-critical operations. The unique crystalline structure of our iron-nickel alloys provides:

Exceptional thermal shock resistance - maintains dimensional stability during rapid temperature transitions

Optimized cryogenic toughness - retains ductility and impact strength at sub-zero temperatures

Corrosion resistance in harsh chemical environments

Low magnetic permeability for sensitive applications

Our customizable manufacturing approach allows for tailored solutions to meet specific operational requirements:

| Parameter | Capabilities |

|---|---|

| Thickness Options | 3mm to 150mm (customizable) |

| Plate Dimensions | Up to 4000mm length × 2000mm width |

| Surface Treatments | Pickled, machined, or polished finish |

| Certification Documentation | Material test reports provided |

These specialized plates serve as critical components in multiple industries including LNG processing equipment, aerospace cryogenic systems, high-temperature reactors, and power generation turbines. The alloy's unique properties significantly reduce thermal stress failures in pressure vessels and containment systems, extending equipment lifespan while minimizing maintenance downtime.

Backed by ISO9001 certified manufacturing processes and supported by our global logistics network, we ensure consistent quality and reliable delivery to industrial operations worldwide. Our technical team provides comprehensive material selection guidance and application engineering support to optimize performance in your specific operating environment.

Frequently Asked Questions

Q: What nickel content range do these alloy plates typically feature?

A: Our standard alloys contain 30-50% nickel content, with specific formulations optimized for either cryogenic stability or high-temperature performance based on application requirements.

Q: Can you supply plates meeting specific international material standards?

A: We regularly produce alloys meeting ASTM, EN, JIS, and GB specifications - please provide your required standard for confirmation.

Q: What is the typical lead time for custom-sized orders?

A: Standard sizes ship within 2-3 weeks, while custom dimensions require 4-5 weeks production time depending on specifications.

Q: Do these plates require special welding procedures?

A: Yes, we provide comprehensive welding procedure specifications with material shipments to ensure proper joint integrity.

Q: What packaging methods do you use for international shipments?

A: Plates are protected with anti-corrosion coating, separated by moisture-resistant materials, and secured in custom-fitted wooden crates.

Discover how our specialized alloy plates can enhance the reliability and safety of your extreme-temperature operations. Contact our metallurgical specialists today for technical consultation and request material test certificates to verify performance specifications for your application requirements.

Send Inquiry to This Supplier

You May Also Like

-

Iron-Nickel Alloy Bar 4J33 in Various Sizes and Diameters for Custom Industrial ApplicationsNegotiableMOQ: 50 Kilograms

-

Standard Dimensions Iron Nickel Alloy Plate 4J36 With Excellent Corrosion Resistance for Medical EquipmentNegotiableMOQ: 50 Kilograms

-

Industrial Grade Iron Nickel Alloy Plate 4J36 Compatible With Scientific Instruments and ToolsNegotiableMOQ: 50 Kilograms

-

High-Quality Iron Nickel Alloy Plate 4J36 for Aerospace Industry Cryogenic ComponentsNegotiableMOQ: 50 Kilograms

-

Custom Sized 4J36 Invar Alloy Plate With Low Thermal Expansion Iron Nickel Alloy Plate for Precision Engineering ApplicationsNegotiableMOQ: 50 Kilograms

-

Industrial Pure Titanium Plate Ta2 With Excellent Formability and Weldability for Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

Precision Titanium Alloy Bar TA15 in Various Diameters (5mm-200mm) for Industrial MachiningNegotiableMOQ: 50 Kilograms

-

Custom Precision Titanium Alloy Bar Stellite6 Factory Marine Corrosion Resistant Titanium Rod SupplierNegotiableMOQ: 50 Kilograms

-

High-Strength Titanium Alloy Bar Stellite12 With Superior Corrosion Resistance for Demanding EnvironmentsNegotiableMOQ: 50 Kilograms

-

Aerospace Application Titanium Alloy Bar for Landing Gear and Structural Components Using TA18NegotiableMOQ: 50 Kilograms