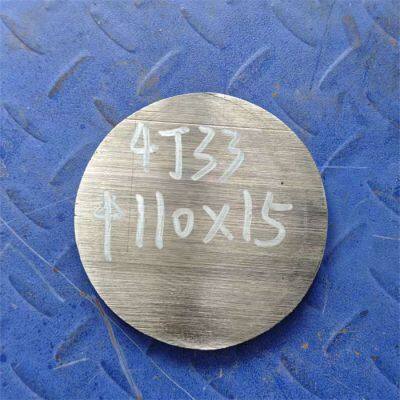

Compatible Iron-Nickel Alloy Bar 4J33 for High-Temperature Environments and Fabrication Processes

The Compatible Iron-Nickel Alloy Bar 4J33 is expertly engineered to thrive in extreme high-temperature environments and demanding fabrication processes, delivering exceptional thermal stability and reliability. Manufactured by Jiangsu Zhonggongte Metallurgical Technology Co., Ltd., a trusted distributor with ISO9001 certification and over US$100 million in annual exports, this alloy bar ensures consistent performance for critical applications in aerospace, electronics, and precision engineering. Its unique composition minimizes thermal stress, enabling seamless integration into complex assemblies while reducing downtime and maintenance costs. With global shipping capabilities from ports like Shanghai and Tianjin, we provide accessible solutions tailored to diverse international markets.

This alloy bar stands out due to its superior low thermal expansion coefficient, which prevents distortion under heat, making it ideal for scenarios involving rapid temperature fluctuations. For instance, in electronic packaging, it maintains dimensional accuracy, while in fabrication processes like welding or machining, it offers excellent workability without compromising structural integrity. Below is a detailed overview of its technical specifications, presented in a table for clarity. Note that values are based on typical industry standards and can be customized to meet specific requirements.

| Property | Value |

| Chemical Composition | Iron (Fe): ~64%, Nickel (Ni): ~33%, Trace elements |

| Density | Approximately 8.1 g/cm³ |

| Melting Point | Around 1430°C |

| Coefficient of Thermal Expansion | Low, typically 1.3 x 10-6/K |

| Tensile Strength | Standard range: 400-600 MPa |

| Hardness | Customizable, often 150-200 HB |

Key advantages include enhanced durability in corrosive settings, such as chemical processing plants, and ease of fabrication for custom shapes and sizes. These benefits translate into tangible client advantages:

Cost Efficiency: Reduces material waste and rework by maintaining precision during high-heat operations.

Versatility: Suitable for diverse industries, from automotive tooling to medical devices, due to its adaptable properties.

Improved Product Lifespan: Resists fatigue and cracking, lowering replacement frequency and total ownership costs.

Applications span multiple sectors, with the alloy bar being particularly effective in:

Aerospace components like engine mounts, where thermal stability is critical.

Electronics for semiconductor fixtures, ensuring minimal expansion-induced failures.

Industrial fabrication, including mold bases and dies, for consistent performance under stress.

For clients, this means faster project turnarounds and higher-quality end products. Our company supports this with flexible options, such as custom sizing and bulk wholesale discounts, backed by a robust supply chain that serves markets from North America to Africa.

In summary, the 4J33 Iron-Nickel Alloy Bar delivers unmatched reliability for high-temperature and fabrication challenges, backed by our ISO9001 quality assurance and global logistics network. With quick response times and samples available upon request, partnering with us ensures seamless integration into your operations. Contact Jiangsu Zhonggongte Metallurgical Technology today to discuss your specific needs or request a competitive quote—experience the difference in performance and service.

What makes 4J33 alloy suitable for high-temperature environments? Its low thermal expansion coefficient minimizes dimensional changes under heat, ensuring stability in applications like furnaces or aerospace engines.

Can I get custom sizes for the alloy bar? Yes, dimensions are fully customizable upon request to fit your fabrication requirements.

Is the alloy corrosion-resistant? It offers good resistance to oxidation and corrosion, particularly in controlled environments, but specific performance depends on conditions.

What is the typical lead time for orders? Lead times vary based on customization; standard shipments can be arranged quickly from ports like Shanghai.

How does 4J33 compare to other iron-nickel alloys? It shares similarities with alloys like Invar but is optimized for compatibility in fabrication; detailed comparisons are available upon inquiry.

Are there minimum order quantities? MOQs are flexible, catering to both small and large-scale projects; contact us for specifics.

What certifications apply to this product? It is produced under an ISO9001-certified quality management system, ensuring consistent standards.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Grade Iron Nickel Alloy Plate for Cryogenic and High-Temperature EnvironmentsNegotiableMOQ: 50 Kilograms

-

High-Performance Iron-Nickel Alloy Bar With Controlled Thermal Expansion for Precision EngineeringNegotiableMOQ: 50 Kilograms

-

Durable Iron-Nickel Alloy Bar 4J33 With Low Thermal Expansion and Corrosion Resistance PropertiesNegotiableMOQ: 50 Kilograms

-

High-Performance Iron-Nickel Alloy Bar 4J33 for Precision Instrument and Medical Device ComponentsNegotiableMOQ: 50 Kilograms

-

Precision Machinable Iron Nickel Alloy Bar for Cryogenic and Aerospace ApplicationsNegotiableMOQ: 50 Kilograms

-

Industrial Pure Titanium Plate Ta2 With Excellent Formability and Weldability for Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

China Manufacture Alloy Steel Round Bar 738 1.2738 Stainless Steel BarNegotiableMOQ: 1 Ton

-

China Hot Rolled Black Polished Price ASTM 201/304/316/2205/310S Duplex Alloy Stainless Steel Round BarNegotiableMOQ: 1 Ton

-

Stainless Steel Bar Alloy Rod Stainless Steel J91153 Round Bar Stainless Steel Bar PriceNegotiableMOQ: 1 Ton

-

Cold Work Drawn Alloy Tool Stainless Steel HSS Round Bar Best Quality Steel Round Bar 440B Stainless Steel BarNegotiableMOQ: 1 Ton