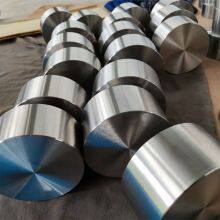

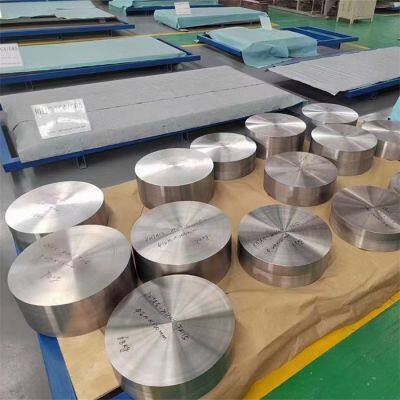

Precision Titanium Alloy Bar TA15 in Various Diameters (5mm-200mm) for Industrial Machining

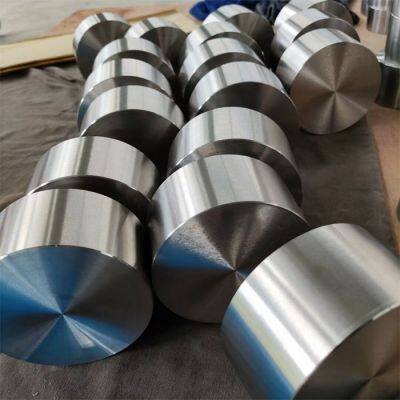

Our Precision Titanium Alloy Bar TA15 is engineered to deliver exceptional performance for demanding industrial machining applications, offering a versatile diameter range from 5mm to 200mm to accommodate diverse project needs. Crafted from high-quality TA15 titanium alloy, this bar provides superior strength-to-weight ratio and outstanding corrosion resistance, ensuring reliability in harsh environments. With ISO9001 certification backing its quality, it stands as a dependable choice for industries requiring precision and durability, backed by Jiangsu Zhonggongte Metallurgical Technology Co., Ltd.'s global export expertise.

The TA15 titanium alloy used in these bars is renowned for its excellent weldability and thermal stability, making it ideal for high-stress machining operations. Key features include:

Enhanced Precision: Tight tolerances ensure consistent dimensions for seamless integration into CNC and lathe machining processes.

Corrosion Resistance: Resists degradation from chemicals and moisture, extending product lifespan in industrial settings.

Customization Options: Surface finishes and lengths are customizable upon request to meet specific customer requirements.

Global Availability: Shipped from major ports like Shanghai and Tianjin, ensuring efficient delivery to markets worldwide.

Technical specifications highlight the bar's adaptability, with detailed parameters presented in the table below. The diameter range allows for applications in aerospace components, medical devices, and automotive parts, providing benefits such as reduced material waste and improved machining efficiency.

| Diameter (mm) | Common Applications | Material Properties |

|---|---|---|

| 5-20 | Small precision parts, fasteners | High tensile strength, lightweight |

| 21-50 | Tooling components, shafts | Excellent fatigue resistance |

| 51-100 | Structural frames, valves | Good thermal stability |

| 101-200 | Large industrial machinery parts | Superior corrosion resistance |

Customers benefit from reduced operational costs due to the bar's long service life and ease of machining, supported by Jiangsu Zhonggongte's responsive supply chain across North America, Europe, Asia, and other key regions.

Invest in our TA15 titanium alloy bars to elevate your industrial projects with a product that combines precision engineering and robust performance. With over US$100 million in annual exports and a dedicated team, we ensure timely delivery and tailored solutions. Contact us today for a quote or to discuss custom requirements—enhance your machining capabilities with a trusted partner in metallurgical technology.

Frequently Asked Questions (FAQ)

Q: What is TA15 titanium alloy, and why is it suitable for machining?

A: TA15 is a high-strength titanium alloy known for its excellent weldability and corrosion resistance, making it ideal for precision machining due to its stability under stress and compatibility with CNC processes.

Q: What diameter options are available for the titanium bars?

A: The bars come in diameters ranging from 5mm to 200mm, catering to various industrial needs; specific sizes can be selected based on application requirements.

Q: Can I request custom lengths or surface finishes?

A: Yes, customization for lengths and surface finishes is available upon request to ensure the bars meet your exact project specifications.

Q: What certifications does the product have?

A: The bars are ISO9001 certified, guaranteeing consistent quality and compliance with international standards for industrial use.

Q: How are shipments handled, and what are the lead times?

A: Shipments are arranged from ports like Shanghai or Tianjin; lead times vary based on order size and destination but are optimized for efficiency.

Q: Which industries commonly use these titanium bars?

A: They are widely used in aerospace, automotive, medical device manufacturing, and general industrial machining for components requiring high precision and durability.

Q: Are there any special storage or handling instructions?

A: Store in a dry, cool environment to prevent oxidation; handle with standard machining protocols to maintain surface integrity.

Send Inquiry to This Supplier

You May Also Like

-

Customizable Titanium Alloy Tube Processed to Customer Drawings With Black or Bright FinishNegotiableMOQ: 1 Ton

-

High-Strength Corrosion-Resistant Titanium Alloy Tube for Enhanced PerformanceNegotiableMOQ: 1 Ton

-

Complete Range of Titanium Alloy Tubes in Various Sizes With Black or Bright Surface OptionsNegotiableMOQ: 1 Ton

-

Industrial-Grade Titanium Alloy Tube Designed for Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

High Strength Titanium Alloy Pipe Manufacturer for Marine and Offshore EngineeringNegotiableMOQ: 1 Ton

-

Durable Ta2 Titanium Alloy Plate for Aerospace Components and Medical Device ApplicationsNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Plate Ta2 With Lightweight Corrosion Resistance for Industrial EquipmentNegotiableMOQ: 1 Ton

-

Titanium Alloy Plate Ta2 in Custom Sizes and Thicknesses for Precision Engineering ProjectsNegotiableMOQ: 1 Ton

-

Lightweight and Corrosion-Resistant Titanium Alloy Bar TC4 for Marine and Offshore EquipmentNegotiableMOQ: 1 Ton

-

Aerospace Application Titanium Alloy Bar TC11, Compatible With Aircraft Frames and Satellite ComponentsNegotiableMOQ: 1 Ton