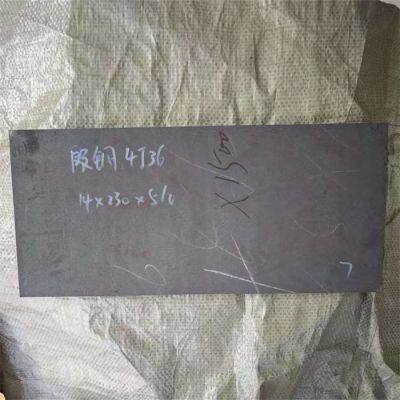

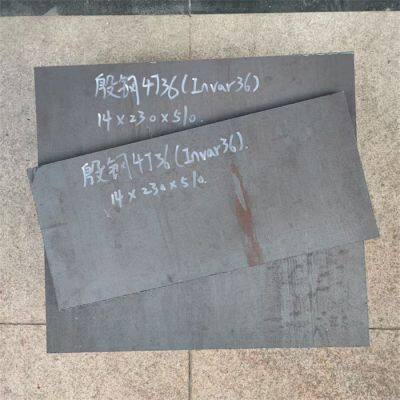

Standard Dimensions Iron Nickel Alloy Plate 4J36 With Excellent Corrosion Resistance for Medical Equipment

Discover the precision-engineered 4J36 Iron Nickel Alloy Plate specifically designed for critical medical equipment applications. This specialized material delivers exceptional corrosion resistance and unmatched dimensional stability in temperature-sensitive environments. With its ultra-low thermal expansion properties, it ensures reliability in MRI machines, surgical instruments, and diagnostic devices. Manufactured under strict quality protocols, our alloy plates maintain consistent performance in sterile medical settings where material integrity is non-negotiable.

As a distributor with ISO9001 certification and global export experience, we guarantee material traceability and compliance with international medical standards. Our plates undergo rigorous testing to meet the stringent requirements of life-saving equipment, providing OEMs with a trusted solution for high-precision components.

Key technical advantages include:

Thermal stability - Coefficient of thermal expansion as low as 1.6×10-6/K (20-100°C)

Corrosion resilience - Resists bodily fluids, disinfectants, and sterilization processes

Machinability - Maintains dimensional accuracy during CNC processing

Biocompatibility - Suitable for implantable device components (upon request)

Material purity - Controlled composition with ≤0.05% carbon content

Technical specifications for standard grades:

| Property | Value | Test Standard |

|---|---|---|

| Density | 8.1 g/cm³ | ASTM B193 |

| Tensile Strength | 440-590 MPa | ASTM E8 |

| Yield Strength | 280 MPa min | ASTM E8 |

| Elongation | 30% min | ASTM E8 |

| Max Service Temp | 400°C | ASTM E228 |

In medical imaging equipment, the alloy's near-zero expansion characteristics prevent calibration drift in temperature-fluctuating environments. For surgical tools, it provides superior fatigue resistance during repeated sterilization cycles. The material's non-magnetic properties ensure compatibility with sensitive electronic components, while its weldability allows seamless integration into complex assemblies.

Our manufacturing partners utilize vacuum induction melting to achieve precise nickel content (36±0.5%) with controlled trace elements. Post-production, plates undergo ultrasonic testing to detect internal flaws and eddy current inspection for surface integrity. Available with custom certifications including material test reports (MTRs) and origin documentation.

Frequently Asked Questions:

Q: What makes 4J36 suitable for medical devices?

A: Its unique combination of corrosion resistance, thermal stability, and biocompatibility meets critical healthcare requirements.Q: Can you provide custom-sized plates?

A: Yes, we offer waterjet cutting and machining services for bespoke dimensions with ±0.1mm tolerance.Q: What quality documentation is available?

A: All shipments include material certificates with chemical analysis and mechanical test data per EN 10204 3.1.Q: How does thermal expansion affect medical instruments?

A: Minimal expansion prevents calibration errors in temperature-sensitive devices like laser surgical tools.Q: What packaging is used for medical-grade plates?

A: We use VCI-coated waterproof wrapping with edge protectors to prevent contamination during transit.Q: Are there alternatives for MRI applications?

A: 4J36 is preferred for its non-magnetic properties, but we can advise on alternatives like titanium alloys.

With ISO9001-certified quality management and shipments from Shanghai/Tianjin ports, we ensure timely delivery to medical equipment manufacturers worldwide. Our technical team provides application engineering support from prototype development to volume production. Contact us for alloy selection guidance, sample requests, or volume quotations – let our expertise enhance your medical device reliability.

Serving OEMs across North America, Europe, and Asia since 2022, we maintain an annual export volume exceeding $100 million. Request material specifications today to discover how our 4J36 plates can optimize your medical equipment performance while reducing lifecycle costs.

Send Inquiry to This Supplier

You May Also Like

-

Durable Iron-Nickel Alloy Bar 4J33 With Low Thermal Expansion and Corrosion Resistance PropertiesNegotiableMOQ: 50 Kilograms

-

High-Performance Iron-Nickel Alloy Bar 4J33 for Precision Instrument and Medical Device ComponentsNegotiableMOQ: 50 Kilograms

-

Precision Machinable Iron Nickel Alloy Bar for Cryogenic and Aerospace ApplicationsNegotiableMOQ: 50 Kilograms

-

Compatible Iron-Nickel Alloy Bar 4J33 for High-Temperature Environments and Fabrication ProcessesNegotiableMOQ: 50 Kilograms

-

Iron-Nickel Alloy Bar 4J33 in Various Sizes and Diameters for Custom Industrial ApplicationsNegotiableMOQ: 50 Kilograms

-

Industrial Pure Titanium Plate Ta2 With Excellent Formability and Weldability for Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

China Manufacture Alloy Steel Round Bar 738 1.2738 Stainless Steel BarNegotiableMOQ: 1 Ton

-

China Hot Rolled Black Polished Price ASTM 201/304/316/2205/310S Duplex Alloy Stainless Steel Round BarNegotiableMOQ: 1 Ton

-

Stainless Steel Bar Alloy Rod Stainless Steel J91153 Round Bar Stainless Steel Bar PriceNegotiableMOQ: 1 Ton

-

Cold Work Drawn Alloy Tool Stainless Steel HSS Round Bar Best Quality Steel Round Bar 440B Stainless Steel BarNegotiableMOQ: 1 Ton