304H Stainless Steel Coil for Food Processing, 1.4529/316L, Offering Thermal Stability

304H Stainless Steel Coil for Food Processing: A Premium Solution with 1.4529/316L Compatibility and Thermal Stability

1. Product Overview

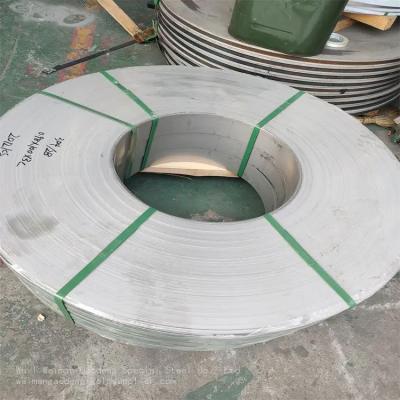

Our 304H stainless steel coil is a high - quality product specifically designed for food processing applications. With a composition that includes elements from the 1.4529/316L series, it combines the best of both worlds in terms of corrosion resistance and mechanical properties. The coil is produced using advanced hot - rolled techniques, ensuring a uniform and dense internal structure. The surface of the coil is polished, giving it a smooth and clean finish that is not only aesthetically pleasing but also highly practical in food processing environments.

2. Material and Standard Compliance

This stainless steel coil adheres to the ASTM standard, which is widely recognized and respected in the international market. The 304H grade is known for its high carbon content compared to regular 304 stainless steel, which provides enhanced strength and thermal stability. The addition of elements from the 1.4529/316L series further improves its corrosion resistance, especially in environments where it may come into contact with various food substances, acids, and alkalis. This makes it an ideal choice for food processing equipment such as tanks, conveyors, and processing lines.

3. Thermal Stability

One of the key features of our 304H stainless steel coil is its excellent thermal stability. In food processing, many operations involve high - temperature processes such as cooking, sterilization, and pasteurization. Our coil can withstand these high temperatures without significant deformation or loss of mechanical properties. This means that equipment made from our coil can maintain its structural integrity during long - term high - temperature use, reducing the risk of equipment failure and ensuring the safety and quality of the food products being processed.

4. Corrosion Resistance

In the food processing industry, corrosion is a major concern as it can contaminate food products and lead to equipment damage. Our 304H stainless steel coil, with its 1.4529/316L - influenced composition, offers superior corrosion resistance. It can resist corrosion from a wide range of substances commonly found in food processing, including organic acids, salts, and cleaning agents. This not only extends the lifespan of the equipment but also helps to maintain a hygienic environment, which is crucial for food safety.

5. Manufacturing and Processing Capabilities

Our company, Wuxi Weiman Gaodeng Special Steel Co., Ltd., is a professional manufacturer with extensive experience in producing high - precision special steel products. We have advanced processing and testing capabilities. For this stainless steel coil, we can provide custom - cutting services for plates (with a maximum thickness of 120mm) and pipes (with an outer diameter ranging from 20 - 1200mm). We also offer welded elbows and flanges per ASME B16.9, with radiographic testing (RT) and liquid penetrant testing (PT) to ensure the quality of the joints.

6. Quality Assurance

We are committed to providing high - quality products. Our production process is strictly controlled, and we have advanced non - destructive testing (NDT) services. Ultrasonic Testing (UT) to EN 10228 - 3 can detect internal defects as small as 0.5mm, and Magnetic Particle Testing (MT) is used for surface cracks, which are certified by SGS and BV. This ensures that every coil we produce meets the highest quality standards.

7. Global Reach and Market Presence

Our company has a wide export share, ranging from US$5 Million - US$10 Million. We serve major markets across the globe, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid - East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. Our team of 11 - 20 experienced salespeople is dedicated to providing excellent customer service and support to our international clients.

8. Company History and Expertise

Since our establishment in 2003, we have evolved from a company focused on R & D and material solutions for power plant boiler steel to a global special steel solution provider. We have achieved significant milestones over the years, such as getting ISO 9001:2015, API 5L, EU PED certifications in 2017. Our collaboration with industry giants like Germany’s DMV Mannesmann and participation in major projects like Saudi Aramco’s Jazan Power Plant demonstrate our technical strength and reliability.

9. Expert Team

Our leadership team is composed of highly experienced professionals. Mr. Sang Le, our CEO, has over 20 years of experience in the special steel industry and is well - versed in EU/US market compliance. Dr. Li Wei, our Chief Metallurgist, holds a PhD in Materials Science from Tsinghua University and specializes in creep - resistant alloys and titanium metallurgy. Our technical staff includes 12 ASME - certified NDT Level III inspectors and 5 NADCAP - qualified engineers, ensuring the high - quality production and processing of our products.

In conclusion, our 304H stainless steel coil for food processing, with its 1.4529/316L compatibility and thermal stability, is a reliable and high - performance product that can meet the demanding requirements of the international food processing market.

Send Inquiry to This Supplier

You May Also Like

-

S31803 Stainless Steel Coil for Marine Applications, 1.4460/S32205, With Excellent Wear ResistanceNegotiableMOQ: 1 Ton

-

316LMOD Stainless Steel Coil for Chemical Storage Tanks, 2205/347H, Offering Long-Lasting DurabilityNegotiableMOQ: 1 Ton

-

F60 Stainless Steel Coil for Pharmaceutical Equipment, 1.4547/316L, With Strength and SterilityNegotiableMOQ: 1 Ton

-

SUS329J1 Stainless Steel Coil for Automotive Manufacturing, 1.4435/S30409, With High Corrosion ResistanceNegotiableMOQ: 1 Ton

-

316Ti Stainless Steel Coil for Heat Exchangers, 1.4529/2507, With Exceptional Mechanical StrengthNegotiableMOQ: 1 Ton

-

2205 Stainless Steel Coil for Structural Steel, 1.4460/SUS630, Offering High ToughnessNegotiableMOQ: 1 Ton

-

1.4435 Stainless Steel Coil for Petrochemical Industry, 316H/S32205, With Heat and Corrosion ResistanceNegotiableMOQ: 1 Ton

-

S32750 Stainless Steel Coil for Marine Applications, F52/347H, With Superior Stress ResistanceNegotiableMOQ: 1 Ton

-

S31668 Stainless Steel Coil for Power Plants, 1.4547/316H, With High-Temperature PerformanceNegotiableMOQ: 1 Ton

-

SUS329J1 Stainless Steel Coil for Aerospace Components, S34778/F51, Offering Strength and Corrosion ResistanceNegotiableMOQ: 1 Ton