Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating Temperature

-40℃~70℃

Storage Temperature

-55℃~85℃

Relative Humidity

5% - 95% (non-condensing)

Size

160mm×100mm×45mm

I. Overview

TRICONEX 9771 7400195-210/3000656-210 is a triple-redundant digital input module belonging to the TRICONEX Tricon series Safety Instrumented System (SIS) product family. Its core positioning is to address the key requirements of industrial high-risk scenarios, including "accurate acquisition of safety signals, triple-redundant fault tolerance, stable operation in extreme environments, and rapid response to safety interlocks". It provides an integrated solution of "signal isolation - redundant acquisition - fault diagnosis - safe transmission" for safety control systems in industries such as petrochemicals, nuclear power, oil and gas extraction, and pharmaceuticals (e.g., reactor overpressure interlock, tank farm fire alarm, and nuclear island cooling system fault shutdown). This ensures the reliable acquisition and uninterrupted transmission of safety signals in industrial sites, complies with the IEC 61508 SIL 3 safety standard, and reduces the risk of safety accidents caused by equipment failures.

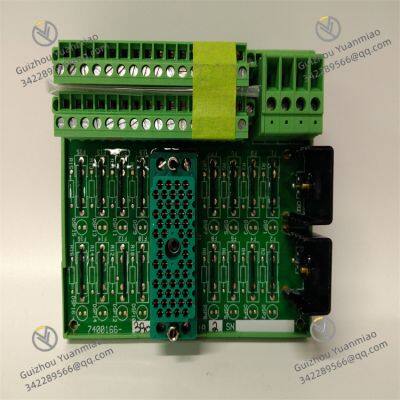

The TRICONEX 9771 adopts an industrial-grade reinforced triple-redundant architecture with dimensions of 160mm×100mm×45mm. It is compatible with standard 3U racks (10-slot/16-slot) of the TRICONEX Tricon series and supports parallel expansion of multiple modules (up to 12 modules), meeting the signal acquisition needs of large-scale safety systems. The core of the module adopts a "three-channel independent acquisition + central voting" design. Each input channel is equipped with an independent signal isolation circuit and AD converter, paired with a dedicated redundant communication chip, realizing triple redundancy in the entire link of "acquisition - transmission - diagnosis". The housing is made of UL94 V-0 grade flame-retardant alloy material with an IP20 protection rating, and has a built-in dust filter and anti-salt spray coating to enhance protection against dust and corrosion in marine environments. It has an operating temperature range of -40℃~70℃ and a relative humidity of 5%~95% (non-condensing), making it compatible with low-temperature polar oil and gas platforms and high-temperature refining units. Internally, it adopts a "channel-level independent isolation + module-level electromagnetic shielding" design. The isolation voltage between each input channel and the backplane bus is ≥2.5kVrms, and it has ESD protection of ±8kV (air discharge), effectively resisting strong electromagnetic interference in industrial sites (such as high-voltage frequency converters and startup shocks of large motors). The Mean Time Between Failures (MTBF) is ≥250,000 hours (per Telcordia standard at 25℃). It is compatible with TRICONEX TriStation 1131 programming software, supports seamless connection with Tricon SIS controllers, meets SIL 3 safety certification requirements, and reduces the difficulty of system integration.

II. Technical Parameters

1. Electrical and Input Parameters

2. Redundancy and Safety Parameters

3. Environmental and Reliability Parameters

III. Functional Characteristics

1. Triple-Redundant Fault-Tolerant Design

With "uninterrupted safety" as its core, the TRICONEX 9771 achieves highly reliable acquisition of safety signals through a triple-redundant architecture and intelligent voting logic:

Three-Channel Independent Acquisition: Each of the 16 input signals is equipped with 3 independent acquisition channels (including independent AD converters and isolation circuits). The acquired data is transmitted to the central voting unit in real time, avoiding signal loss caused by single-channel failure. In the control of reactors in ethylene plants, if one channel for overpressure signal acquisition fails, the other 2 channels can still collect signals normally. The system judges the validity of the signal through the "2-out-of-3" voting logic, without affecting the emergency pressure relief interlock action.

Flexible Voting Logic: It supports two voting modes: "2-out-of-3" (2oo3) and "1-out-of-3" (1oo3), which can be configured via software according to scenario requirements. In nuclear power cooling systems, the "2-out-of-3" mode (action is triggered only when signals from 2 or more channels are consistent) is adopted to reduce the risk of false actions; In the oil and gas wellhead shutdown system, the "1-out-of-3" mode (action is triggered by one channel signal) is adopted to improve the emergency response speed.

Fault Self-Shielding and Alarm: When an open circuit, short circuit, or signal drift of a single channel is detected, the faulty channel is automatically shielded, and fault information is uploaded to the controller at the same time. Operation and maintenance personnel can locate the faulty channel (e.g., "Channel 8 open circuit fault") through the HMI, and complete channel repair without shutting down the system, increasing the system availability to 99.999%.

2. High-Precision Safety Signal Acquisition

In response to the demand for "high precision and low latency" in industrial safety signal acquisition, the module ensures reliable signal acquisition through hardware optimization and signal processing technology:

Low-Latency Response: The signal response time is ≤10ms (typical value 5ms), which is much faster than traditional dual-redundant modules (response time ≥20ms), meeting the rapid response requirements of emergency interlock scenarios. In the reactor overpressure interlock, when the pressure reaches the overpressure threshold (e.g., 10MPa), the module collects the overpressure signal and uploads it to the controller within 5ms, and the controller triggers the pressure relief valve action within 10ms. The total response time is ≤15ms, avoiding reactor overpressure and out-of-control.

Adaptive Debounce Configuration: It supports software-adjustable debounce time of 1-100ms, adapting to different types of input devices. For mechanical pressure switches (bounce time 5-10ms), a 10ms debounce time is configured to avoid false alarms caused by contact bounce; For photoelectric flame detectors (bounce time ≤1ms), a 1ms debounce time is configured to ensure rapid acquisition of fire signals.

Wide-Range Signal Compatibility: It supports 24V DC wet contact and voltage-free dry contact input, without the need for additional signal conversion modules, adapting to common safety switches, buttons, detectors, and other devices in industrial sites. In the safety system of clean rooms in the pharmaceutical industry, it can simultaneously collect 12 channels of dry contact emergency stop button signals and 4 channels of wet contact high-temperature alarm signals, simplifying system wiring and configuration.

3. Strong Anti-Interference and Extreme Environment Adaptability

In response to the operating conditions of "strong electromagnetic interference and harsh environments" in industrial high-risk scenarios, the module ensures long-term stable operation through hardware protection design:

Multi-Layer Electromagnetic Isolation: The isolation voltage between channels and between channels and the backplane is ≥2.5kVrms, combined with ESD protection of ±8kV. In environments surrounded by high-voltage frequency converters (10kV) and large motors (10MW), the signal acquisition error is ≤0.1%, and no false signals are triggered. In the blast furnace gas recovery system of a steel plant, even if there are 10 frequency converters nearby, the module can accurately collect the high gas pressure signal, avoiding energy waste caused by false shutdown.

Wide-Temperature and Corrosion Resistance: With a wide-temperature design of -40℃~70℃, the module maintains stable acquisition performance in outdoor oil and gas tank farms in northern winters (-35℃) or refining units in southern summers (65℃); The anti-salt spray coating and IP20 dust-proof design enable it to operate continuously for 2 years in the high-salt spray environment of offshore oil and gas platforms without corrosion or dust blockage, meeting the ISO 12944-5 C5-M high-corrosion environment standard.

Vibration and Shock Resistance: It has a vibration resistance rating of 2g (10-500Hz) and a shock resistance rating of 15g (11ms). In the blasting environment of underground mines, the module has no solder joint detachment or interface loosening, ensuring reliable acquisition of fault signals from the underground ventilation system.