Home > Products > BELT SCALE > Full Floating Balance Array High Precision Electronic Belt Scale

Full Floating Balance Array High Precision Electronic Belt Scale

≥1 Combos

- SHANGHAI

- T/T

- 20 days

You May Like

Product Details

| Warranty | 12MONTHS | After-sales Service | REMOTE | |

| Transport Package | WOODBOX | Trademark | WEIGHTEC | |

| Origin | CHINA |

Product Description

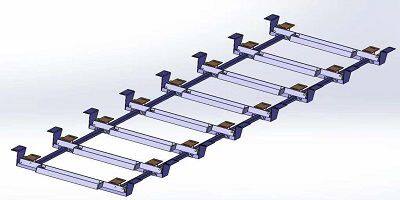

Full floating balance array high precision electronic belt scale AICS-FH-WTC

Array-type high-precision electronic belt scales offer long-term stability without calibration, with significantly improved weighing accuracy and excellent durability. The load cell stiffness requirements are substantially reduced, and weight reduction effectively mitigates the impact of belt tension variations. Installation position requirements are relaxed as single support eliminates structural deformation interference. Reduced coaxiality requirements for weighing rollers minimize maintenance needs. Material adhesion on rollers has no effect. Suitable for trade settlements and critical bulk material measurements. Equipped with expert system remote diagnostics enabling early fault detection, warning, and resolution. Achieves 0.2% accuracy, meeting true Class 0.2 measurement standards with over 6 months of stable operation. Unique tracking system prevents zero drift, with individual AD detection for each sensor channel. Features fault diagnosis and deviation rejection, ensuring long-term high-precision operation. Truly realizes high-accuracy, self-calibration, and maintenance-free operation, guaranteeing precise measurement. The main indicators of the high-precision belt scale are AICS8000 intelligent controller and belt scale accumulator Rated flow rate 30t/h---13000t/h Physical verification error: Single count n=12; ≤ 0.1% (first verification); ≤ 0.2% (in use) Number of sequence units n ≤ 12 Effective weighing section length 2L×n (L: roller spacing) Piglet width 500---2400mm Pit belt speed 0.5---5m/s The belt type machine numbers are TD75 and DTⅡ Communication protocol standard MODBUS Communication interface RS-485, RS-232, Ethernet Technical breakthrough of high precision belt scale Discard the traditional belt scale error theory and create a new error theory. The main error sources of belt scale are —— The influence of belt tension is basically eliminated Traditional belt scale error theory high precision to the "internal force theory" of belt scale For a single weighing unit, the influence of belt tension is identical to that in traditional belt scale configurations. In a continuously installed weighing array, adjacent units' belt tensions cancel each other out. This means the internal belt tension within a continuous weighing array acts as an "internal force" with zero impact on weighing performance, while the effect of belt tension is confined to the entry and exit units of the array. 12 Belt effect theory of roller belt scale The "belt effect" refers to the impact of physical characteristics such as belt hardness and weakness on weighing. Under belt tension, trough-shaped belts exhibit semi-rigid behavior. When support points are not aligned in a straight plane, waves form along the belt's direction of movement, creating a phenomenon known as the "belt effect" that affects weighing accuracy. The intensity of this effect varies with factors including belt hardness, material flow rate, environmental flow conditions, and temperature. Array-type belt scales compensate for these effects by detecting and analyzing sampling values from each unit to establish a mathematical model of "belt effect" influence. Guided by "internal force theory," these scales adopt a fundamentally different design approach compared to conventional models. Their unique overall structure enables long-term operation under harsh working conditions, playing a crucial role in enhancing the equipment's long-term stability. The unit uses a weighing sensor to support two sets of weighing idler groups. The unique structure design with high bending resistance is simple in structure, light in weight, and quick and convenient for on-site installation. The weighing idler groups use the original idler group of the belt conveyor to avoid maintenance during daily work Force-measuring weighing sensor The weighing sensor used in the belt scale is a special sensor developed through multi-directional research. The sensor has excellent performance indexes such as resistance to horizontal force and offset load, and the overall performance is greatly improved. Technical parameters of high precision electronic belt scale (working voltage 220vac)。

Contact Us

- Xuzhou Weightec Measurement & Control Technology Co.,ltd

- Contact namezhang Chat Now

- Phone86-0516-87791695

- Addresskingdom, Xuzhou, Jiangsu

Product Categories

| weighing indicator | LOADCELLS | SPEEDCELLS | BELT SCALE |

| COAL FEEDER |

New Products

-

WTC-SZC Gravity Type Batching Scale Feeder

-

Electronic Screw Scale WTC-LSC

-

Inlet Flowmeter DE10/DE20/61H

-

Inlet Flowmeter DE10 (WTC10)

-

Inlet Flowmeter DE20 (WTC20)

-

Physical Verification Device (hopper Scale) LCS-PJ

-

Cuboid Metering Management System for Furnace WTC-SMMS

-

Powder Chemical Ton Packaging Scale WTC-TJX

-

Chain Code Verification Chain Code WTC-CLM/XLM

-

Dynamic Link Code Verification Device WTC-XLM

-

Weighing and Quantitative Feeder JGC-30

-

Weighing Feeder JGC-40

-

Pressure Resistant Closed Weighing Feeder NJCG/F55/F57

-

Weighing Controller DM8350B/SCONT-61P/MCS-9105 Computer Accumulator SH500-A

-

Give Coal Machine Controller Belt Scale Accumulator MTZD6000

-

MODWTA75-03/WTA-75-03-03/WTA-75-03 Belt Weighing Integrator

-

Indicator 6001B/ Feeder Controller6105B/ Indicator 6000

-

INDICATOR 6000/FH-01/FH-02/FH-03/FH-04/FH-05/FH-06/FH-07/FH-08/FH-09/FH-10/FH-11

-

Wall-mounted Calculator 201/ Embedded Calculator HN9001

-

Embedded Indicator 2001/ Weighing Controller CFC-2000/CFC201

-

Weighing Control Instrument/ Weighing Accumulation Instrument DL-9901KY

-

Weighing Control Instrument XZSYDL-DL9902J/ Chain Code Instrument DL9801J

-

Shenke Instrument VEG20610 INTECONT

-

Belt Scale Instrument/generator LCXK-III/SMQL0808-II

Recommended Products

- Weighing Machine With Control Unit (Model: DS556070) 2024 Model

- KING MODEL (model:i-MIT-m)

- Intelligent Weighing System

- Load Cell/Sensor/Weighing Modular/junction Box

- KELI/ZEMIC/YAOHUA/MAVIN LOADCELL and Weighing Indicator

- Truck Sclae/weighbridge/Unattended Truck Scale System Serial

- Pallet Scale Series

- Platform Scale Solutions

- TEST WEIGHT

- Belt Scale Instrument/generator LCXK-III/SMQL0808-II

- Shenke Instrument VEG20610 INTECONT

- Weighing Control Instrument XZSYDL-DL9902J/ Chain Code Instrument DL9801J

Find Similar Products By Category

- Instruments & Meters > Weighing & Measuring Apparatus > Other Weighing & Measuring Apparatus

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile