Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

-20°C to 70°C

Output voltage

24V AC

I. Overview

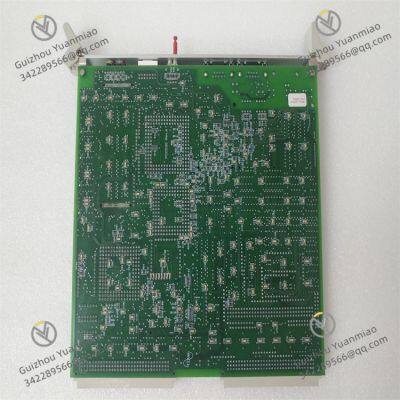

TEAM BG0090 is a high-performance industrial control module. Its excellent performance and reliability have made it occupy an important position in fields such as manufacturing, process control, and industrial automation systems, becoming a powerful assistant for many industrial projects to achieve efficient operation and precise control.

II. Technical Parameters

Power Supply Specification: The working voltage is 220V. This common industrial voltage specification enables it to be conveniently connected to various industrial power supply systems, ensuring stable power supply and meeting the power demand of the module for long-term operation in complex industrial environments.

Interface Configuration: Equipped with rich communication interfaces, among which the Modbus interface is particularly prominent. Through this interface, the module can realize efficient data interaction with other devices supporting the Modbus protocol. Whether transmitting control commands or feeding back device status information, it can be completed accurately and quickly, providing strong support for building large-scale and complex industrial automation networks.

Input and Output Capability: It has multiple input and output channels, which can flexibly process different types of signals and data. These channels can accurately sense changes in the external environment, such as analog signals like temperature, pressure, and flow, as well as digital signals like equipment switch status and pulse signals. The processed results are accurately output to control various actuators, realizing precise regulation of the industrial production process.

III. Functional Features

High Versatility: Due to its multi-channel capability and ability to process various signal types, BG0090 is applicable to almost any industrial automation and control system scenarios. Whether it is the precise control of robots in automobile manufacturing production lines or the real-time monitoring and regulation of reactor temperature and pressure in chemical production processes, it can easily handle them, demonstrating excellent versatility.

Excellent Real-time Performance: In the field of industrial control, real-time response is crucial. The BG0090 controller card has strong real-time processing capability, which can analyze and process input signals in a very short time and make corresponding decisions quickly. In high-speed production lines, once abnormal product quality or equipment failure is detected, it can immediately issue an alarm and take corresponding control measures to ensure the continuity of the production process and the stability of product quality.

Flexible Programmability: It supports multiple programming languages, such as C, C++, Python, etc. Users can use these programming languages to custom-program the module according to specific application requirements, making its behavior fully conform to specific industrial production processes. This programmability gives users great autonomy, enabling them to quickly adjust module functions according to changing production needs and improve the flexibility and adaptability of industrial production.

Compact Design and Convenient Installation: Adopting a compact shape design, it is small in size but powerful in function. It can be easily installed in industrial control cabinets with limited space without occupying too much space. At the same time, it is easy to integrate into existing industrial control systems without causing major changes to the original system architecture, greatly improving the efficiency of system integration.

IV. Common Faults and Solutions

Communication Connection Failure

Possible Causes: Damage to the communication cable, such as broken outer skin or internal wire; loose interface, resulting in poor contact due to factors such as vibration in industrial sites; incorrect communication protocol settings, which do not match the protocol of the connected device.

Solutions: Carefully check the communication cable, and if damage is found, replace it with a new one in time; re-plug the interface to ensure a firm connection, and fix the interface with fixing devices if necessary; re-check the communication protocol settings to ensure they are consistent with those of the connected device, such as correct settings of parameters like baud rate, data bits, stop bits, and parity bits.

Abnormal Input and Output

Possible Causes: Hardware damage to input and output channels due to long-term use or overvoltage and overcurrent impact; external signal interference, as there are a large number of electromagnetic interference sources in industrial sites that affect signal transmission; incorrect wiring during installation or maintenance.

Solutions: Use professional testing tools to detect input and output channels, and if hardware damage is confirmed, replace the damaged channel module in time; take anti-interference measures, such as adding shielding layers to cables and using filters, to reduce external signal interference; carefully check the wiring and ensure it is correct according to the wiring diagram.

Module Failure to Start Normally

Possible Causes: Power supply problems, such as unstable voltage, loose power cords, or faulty power modules; firmware damage, which may be caused by virus attacks, abnormal power outages, etc.

Solutions: Check the power supply, use a multimeter to measure whether the power voltage is within the normal range, and use a regulated power supply if the voltage is unstable; check whether the power cord connection is firm, and reconnect if loose; if the power module is suspected to be faulty, replace it with a new one. For firmware damage, try to repair it with the official firmware repair tool. If it cannot be repaired, contact the manufacturer to obtain the latest firmware and upgrade it.