Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Supply voltage

24VDC

Operating temperature

-40°C to +85°C

I. Overview

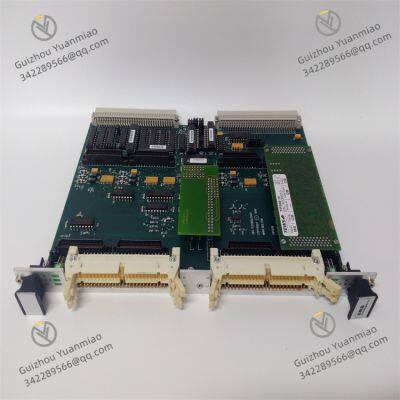

SBS VIPC616 91611524 is a high-performance 6U VME industrial data packet carrier, playing a key role in fields such as industrial automation, data acquisition, and communication. With its excellent design and reliable performance, this product provides stable and efficient data transmission and processing support for various complex systems. By supporting functions such as I/O, ID, memory, and interrupts, it can be seamlessly integrated into multiple industrial application scenarios, meeting the diverse functional requirements of equipment in different industries.

II. Technical Parameters

Interface Type: It adopts a VME bus interface, which is renowned for its high-speed and reliable data transmission characteristics, capable of meeting application scenarios with strict requirements on data processing speed. It also supports on-board Ethernet connection, facilitating communication between the device and external networks, enabling remote data transmission and sharing, thus greatly expanding the application range of the device.

Supported Standards: It fully supports the VME64x standard. Compared with the traditional VME standard, this standard has significant improvements in data transmission rate and system expansion capability, allowing VIPC616 to adapt to the evolving industrial technology needs and ensuring the stable operation of the system under high load and large data volume conditions.

FPGA Technology: It is equipped with customizable FPGA technology, enabling users to program and customize internal logic according to their specific application requirements. This feature endows the product with a high degree of flexibility. Whether it is to implement specific control algorithms in industrial control systems or efficiently process data from different types of sensors in data acquisition systems, personalized needs can be met through FPGA customization.

Operating Temperature: The operating temperature range is -40°C to +85°C, allowing stable operation in extremely harsh environments. Whether in cold outdoor industrial facilities or high-temperature industrial production workshops, it can ensure the normal operation of the equipment, reduce the risk of equipment failure caused by changes in ambient temperature, and improve the reliability and stability of the system.

Dimension Specifications: It has the standard 6U VME slot size. This standardized design facilitates its installation in various VME-compliant cabinets or equipment, working in coordination with other VME modules to achieve system integration and expansion, and is convenient for users to carry out equipment layout and system construction.

Data Transmission Rate: The data transmission rate is up to 100Mbps, which can quickly process and transmit large amounts of data, meeting the demand for high-speed data transmission in scenarios such as industrial automation and data acquisition, effectively reducing data transmission delay and improving the overall operating efficiency of the system.

Integrated Serial Communication Interfaces: It supports RS-232 and RS-422 communication protocols, which are widely used in the industrial field. They can be used to connect various devices with corresponding interfaces, such as sensors and actuators, realizing reliable communication and data interaction between devices, and enriching the connection capability and application scenarios of the device.

III. Functional Features

Multi-slot Design: The carrier board is equipped with four industrial packet slots, supporting the installation and configuration of multiple industrial packets. This multi-slot design provides convenience for system function expansion. Users can insert industrial packets with specific functions, such as data acquisition modules and communication modules, into different slots according to actual needs, realizing the customization and upgrading of system functions, and improving the versatility and applicability of the device.

Flexible I/O Interfaces: Convenient I/O interfaces are provided through unshielded right-angle ribbon connectors on the front panel, which can meet different input and output requirements. Whether connecting sensors to obtain external environment data or controlling actuators to realize device actions, this I/O interface can ensure stable and reliable data transmission, facilitating users to carry out device connection and function realization according to specific application scenarios.

Active LED and Power Monitoring: The front panel of each industrial packet slot is equipped with active LED and power monitoring indicators. The active LED can intuitively display the working status of the module in the corresponding slot, such as whether the module is running normally and whether data transmission is in progress, facilitating users to know the equipment operation status in real-time. The power monitoring indicator allows users to keep abreast of the power status. Once a power abnormality occurs, it can be detected in time and corresponding measures can be taken to ensure the stable operation of the equipment.

Power Management: It is equipped with filtered and fused power rails, which can effectively ensure the stability and safety of the power supply. The filtering function can remove clutter and interference signals in the power supply, providing pure and stable power for the equipment, and avoiding damage to the equipment caused by power fluctuations. The fuse can quickly cut off the circuit when abnormal conditions such as overcurrent occur in the circuit, protecting the electronic components inside the equipment and preventing equipment damage or even safety accidents caused by electrical faults.

Programmable Interrupt Mapping: Customized IRQ (Interrupt Request) mapping can be realized through PLD programming. This function greatly improves the flexibility and expandability of the system. Users can reasonably allocate interrupt resources according to the work priorities and data processing requirements of each module in the system, optimize the system response mechanism, and ensure that the system can operate efficiently and stably in multi-tasking and complex environments.

IV. Common Faults and Solutions

Interface Communication Failure

Possible Causes: Loose interface, which may lead to insecure connection after long-term use or equipment vibration; damaged interface chip, which may be caused by electrical overvoltage, static electricity, etc.; incorrect communication protocol configuration, such as mismatched settings of baud rate, data bits, parity bits, etc. with the connected device.

Solutions: Check the interface connection, re-plug the interface cable to ensure a tight connection; if the interface chip is suspected to be damaged, professional and technical personnel need to use professional tools such as logic analyzers for detection. After confirming the chip damage, replace it with an interface chip of the same model; carefully check the communication protocol configuration, compare it with the manual of the connected device, and ensure that all parameters are set consistently.

Module Not Recognized

Possible Causes: The module is not installed correctly, and it is not installed in place in the slot, resulting in poor electrical connection; slot failure, such as oxidation or damage of the metal contacts inside the slot, affecting the communication between the module and the carrier board; module failure itself, such as short circuit or open circuit in the internal circuit of the module.

Solutions: Reinstall the module to ensure that it is firmly installed in the slot, and follow the correct installation steps and specifications during installation; check the slot, clean the metal contacts inside the slot with alcohol and other cleaning agents, and replace the slot if the contacts are damaged; install the suspected faulty module into other normal slots for testing. If it is still not recognized, it may be a problem with the module itself, and it is necessary to contact the module supplier for repair or replacement.

System Crash or Abnormal Restart

Possible Causes: Unstable power supply, such as power voltage fluctuation and excessive ripple, affecting the normal operation of the equipment; software conflict, compatibility issues between the software running on the equipment and the operating system or other software; hardware overheating, the equipment runs under high load for a long time, and poor heat dissipation leads to excessive hardware temperature, triggering the overheating protection mechanism.

Solutions: Use professional power detection equipment to detect the power supply. If there is a problem with the power supply, replace it with a reliable power module, or add filtering and voltage stabilizing devices at the power input end; check the software installation, uninstall software that may have conflicts, or update the software version to the latest stable version to ensure software compatibility; improve the heat dissipation environment of the equipment, check whether the cooling fan is running normally, clean the dust inside the equipment, and add auxiliary cooling equipment such as heat sinks or cooling fans if necessary to reduce hardware temperature.

Data Transmission Error

Possible Causes: Electromagnetic interference, the presence of strong electromagnetic interference sources nearby, such as large motors and high-frequency equipment, affecting the accuracy of data transmission; damaged data cable, such as broken internal wires and damaged insulation layer of the data cable, leading to abnormal signal transmission; equipment memory failure, memory read-write errors, affecting data storage and transmission.

Solutions: Provide electromagnetic shielding for the equipment, such as using a metal shell and adding a shielding layer, and keep the equipment away from strong electromagnetic interference sources; check the data cable, and replace it in time if damage is found; use professional memory detection tools to detect the equipment memory, and if there is a memory failure, replace the faulty memory module to ensure the accuracy of data storage and transmission.