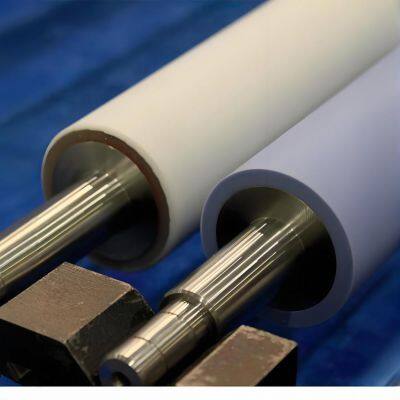

Pu EPDM Rubber Rollers for Digital Textile Flag Printer Fabric Printer Roller Feed Pinch Drive Roller

Textile Printing Machines (Primarily industrial rotary/screen printing machines, and some digital printers)

Core Characteristics: Traditional methods use rotary/screen printing, while modern methods increasingly use digital inkjet units. Processes continuous rolls of fabric. Requires high-precision color registration (multi-color alignment), where tension control is paramount. Belt conveyor (blanket) systems are the mainstream transport method.

Key Roller Requirements (Belt Conveyor System):

Blanket Drive Roll: The absolute core! Drives the entire blanket loop. Requirements: Extremely high dimensional accuracy and stability, extremely high wear resistance, excellent compression set resistance, high coefficient of friction (with blanket underside), heat resistance (downstream drying/curing), resistance to moisture/chemical agents (print pastes, cleaning agents). Special-formulation EPDM or high-quality NBR are preferred. Surface treatments (e.g., lathe-cut spiral grooves) are common.

Blanket Tension Roll: Adjusts blanket tension. Requires high rigidity, wear resistance, dimensional stability. Typically also a rubber-covered roll (EPDM/NBR) or a steel roll.

Blanket Guiding Roll (Web Guiding Roll): Automatically adjusts blanket lateral position to prevent tracking/running off. Requires smooth rotation and high precision. Rubber-covered roll (EPDM/NBR) or steel roll.

Blanket Support Rolls / Carrier Rolls / Idler Rolls: Positioned under the blanket to support the weight of the blanket and fabric, preventing sagging. Numerous in quantity. Require wear resistance and smooth rotation. Commonly steel rolls rubber-covered (EPDM/NBR) or engineering plastic rolls.

Feed-in Roll / Infeed Roll: Pulls fabric onto the blanket. Requires good friction, no fabric damage, resistance to moisture/chemicals. EPDM/NBR/PU.

Fabric Press Roll / Lamination Roll: Presses the fabric onto the blanket (often using a temporary adhesive), preventing shifting. Requires uniform pressure, good elasticity, wear resistance, resistance to adhesive cleaning. Commonly silicone rubber rolls (good elasticity, low adhesion) or PU rolls.

Take-off Roll / Outfeed Roll: Peels the printed fabric off the blanket and conveys it out. Requires good friction; sometimes needs special surface treatment (e.g., threading) to aid peeling. EPDM/NBR/PU.

(Digital Unit) Blanket/Fabric Support Roll (aka Platen Roll): Positioned directly under the print heads, providing precise support for the blanket/fabric to ensure constant print gap/distance. Requires high precision, high rigidity, wear resistance. Typically a hard rubber-covered roll (EPDM) or metal roll.

(Rotary Printing) Central Impression Cylinder (CIC) / Pressure Cylinder: A large steel roll covered with a thick rubber layer; the rotary screen rotates above it during squeegee printing. Requires extremely high compressive strength, elastic recovery, wear resistance, chemical resistance, heat resistance. Special-formulation NBR or EPDM; the thickness and hardness of the rubber layer are crucial parameters.

Product Introduction:

As a roller manufacturer with 47 years of history, our company is ISO 9001 certified. We commit to customers through strict quality control, reliable wooden crate packaging design, timely delivery, and cost-effective products. Every precision roller undergoes rigorous quality inspections before shipment, including:

Dynamic balance precision calibration

Runout measurement

Outer diameter measurement with π tape

Surface roughness testing

Weld seam inspection

Coating thickness measurement

We operate internationally advanced equipment:

▪Polyurethane thermoelastic casting machines (France)

▪ Double-head vacuum platen presses (Taiwan)

▪ Laser measurement systems & triple-roll rubber coating machines (Japan)

▪ Rubber testers (Germany)

▪ Roller winding machines & automated mixing lines (USA)

Supported by 350 production units (including internal mixers, dynamic balancers, CNC lathes) and 1,800+ testing instruments.

Manufacturing Capabilities

Diameter: Max. 2,000mm

Length: Max. 8,000mm

Rubber Materials

NBR, SBR, EPDM, PU, Silicon, CR

Application Industries

Wide-format digital printing | Slitting/rewinding | Textile machinery | Papermaking equipment | Material handling | Glass conveying lines | Packaging machinery | Woodworking | Steel industry

For precise quotation, please provide technical drawings.

Hebei Chunfeng Yinxing Rubber Roller Co., Ltd.

Kevin Ma

Send Inquiry to This Supplier

You May Also Like

-

Solid Polyurethane Monorail Drive Tracking Wheel for Automated Automotive Production Line Amusement EquipmentUS$ 20 - 200MOQ: 5 Pieces

-

Wringer Squeegee Roller Bend Idler Rollers Metallurgy Metallurgical RollerUS$ 100 - 500MOQ: 1 Piece

-

Small Big 10 Inch 6 Inch Rodillo Spike Roller 50mm Spike Rollers for Cotton HarvesterUS$ 200 - 500MOQ: 1 Piece

-

Industrial Rollers Hard Rubber Roller Wood Press Roller Industry Stainless Steel RollerUS$ 100 - 1000MOQ: 1 Piece

-

Conveyor Support Traction Drive Rubber Rollers Roller for Float Glass Smart Production LineUS$ 100 - 300MOQ: 1 Piece

-

Nitrile Rubber Rollers NBR Roller Manufacturer SupplierUS$ 50 - 100MOQ: 1 Piece

-

EPDM Rubber Rollers EPDM Roller Ozone Resistance Weather UV ResistanceUS$ 100 - 500MOQ: 1 Piece

-

Hypalon CSM Rubber Roller Hypalon RollersUS$ 100 - 300MOQ: 1 Piece

-

Fluorocarbon Rubber Rollers FKM FPM Roller Toluene Solvent ResistanceUS$ 500 - 1000MOQ: 1 Piece

-

Metallurgy Rubber RollerUS$ 100 - 1000MOQ: 1 Piece