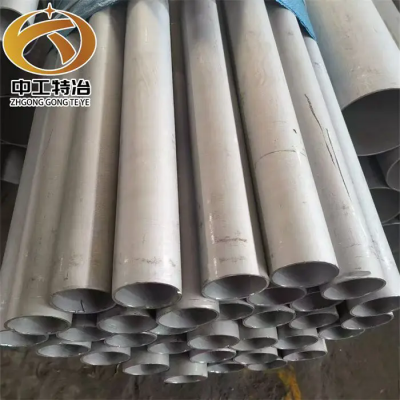

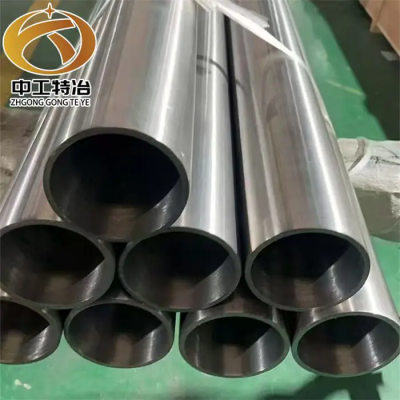

304 316L Compression Stainless Steel Pipe Factory Hospital Use ASTM Standard

304 316L Compression Stainless Steel Pipe for Factory and Hospital Use (ASTM Standard)

1. Product Overview

Our 304 and 316L compression stainless steel pipes are specifically designed for use in factories and hospitals, adhering strictly to the ASTM (American Society for Testing and Materials) standards. These pipes are crafted with precision and high - quality materials, offering exceptional performance and durability in various industrial and medical applications.

2. Material and Surface Treatment

Material

- 304 Stainless Steel: This is a widely used grade of stainless steel known for its excellent corrosion resistance in most environments. It contains 18% chromium and 8% nickel, which provides a good balance between cost and performance. It is resistant to oxidation and can withstand a wide range of temperatures, making it suitable for many factory processes.

- 316L Stainless Steel: The “L” in 316L stands for low carbon, which reduces the risk of carbide precipitation during welding. It has a higher molybdenum content (about 2 - 3%) compared to 304, offering superior corrosion resistance, especially in chloride - rich environments. This makes it an ideal choice for hospital settings where there may be exposure to various chemicals and disinfectants.

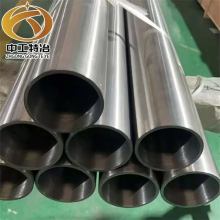

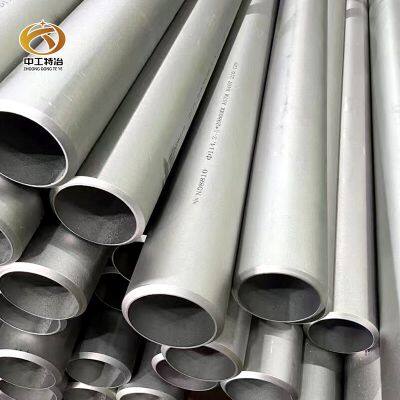

Surface Treatment

The pipes undergo a complete surface treatment process. This not only enhances their aesthetic appearance but also further improves their corrosion resistance. The smooth surface finish reduces the risk of dirt and bacteria accumulation, which is crucial for hospital applications where hygiene is of utmost importance.

3. Manufacturing Techniques

Hot Rolling

Hot rolling is one of the primary manufacturing techniques used in the production of these pipes. During hot rolling, the stainless steel is heated above its recrystallization temperature and then passed through rollers to achieve the desired shape and size. This process helps to refine the grain structure of the steel, improving its mechanical properties such as strength and ductility.

Cold Rolling

After hot rolling, some pipes may undergo cold rolling. Cold rolling is performed at room temperature and is used to achieve a more precise dimensional accuracy and a better surface finish. It also increases the hardness and strength of the pipe, making it more suitable for applications where high - pressure resistance is required.

4. Application in Factories and Hospitals

Factory Use

- Chemical Industry: In chemical factories, these pipes can be used to transport various chemicals due to their excellent corrosion resistance. They can handle acids, alkalis, and other corrosive substances without significant degradation.

- Food and Beverage Industry: The pipes are hygienic and non - toxic, meeting the strict requirements of the food and beverage industry. They can be used for the transportation of food products, water, and other liquids, ensuring the safety and quality of the products.

Hospital Use

- Medical Gas Systems: The pipes can be used to transport medical gases such as oxygen, nitrogen, and carbon dioxide. Their high - quality construction and corrosion resistance ensure the purity and safety of the gases, which is essential for patient care.

- Plumbing Systems: In hospitals, the pipes are used in plumbing systems for supplying water and drainage. Their smooth surface and resistance to bacteria growth help to maintain a clean and hygienic water supply, reducing the risk of water - borne diseases.

5. Quality Assurance

Our company, Jiangsu Zhonggongte Metallurgical Technology Co., Ltd., is a manufacturer with ISO9001 production certification. We have a strict quality control system in place to ensure that every pipe meets the ASTM standards. From raw material inspection to the final product testing, we monitor every step of the production process. Our technical team, composed of sales elites proficient in special alloy knowledge, is always ready to provide professional guidance and support.

6. Company Services

Product Information and Sample Supply

We provide customers with detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality of our pipes.

Price and Negotiation

Based on customer needs, we provide a quotation that includes price, delivery terms, and payment methods. We are willing to negotiate prices to reach a mutually satisfactory agreement.

Order Processing

We accept customer orders and process them with accuracy. We confirm order details such as quantity, model, and delivery time to ensure a smooth transaction.

Production Follow - up and Quality Control

We closely follow up on the production progress to ensure timely delivery. Our quality control team conducts strict inspections to ensure that the products meet customer requirements and standards.

Logistics Arrangement

We arrange transportation and logistics, including shipping, mode selection (sea freight, air freight, etc.), and customs clearance procedures. We track the transportation of goods to ensure they arrive at the customer's designated location smoothly.

After - Sale Service

We handle customer complaints and issues promptly to ensure customer satisfaction. Our customer service team provides 24 - hour uninterrupted high - quality service.

7. Contact Information

If you are interested in our 304 and 316L compression stainless steel pipes, please feel free to contact us. You can reach us via email at zhonggongte@qq.com. Our sales representative, Zhou, can also be contacted on WhatsApp at +8613306184668 or by phone at 86 - 13306184668. Our company is located in Xinwu District.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Pipe Factory Direct Sale 201 304 310 Hot Roll/Cold Roll Steel TubeNegotiableMOQ: 1 Ton

-

304 316 409 Welded Stainless Steel Pipe Tube Manufacturer With Factory PriceNegotiableMOQ: 1 Ton

-

Cold Rolled/Hot Rolled AISI 4130 4140 Rolled Stainless Steel Seamless/Round Tube/Welded PipeNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Manufacturer Stainless Steel 304 316l 904 Pipe 300 Series Alloy for IndustryNegotiableMOQ: 1 Ton

-

Factory Suppliers 201 304 304L 316 316L 430 436 439 409L 904L 310S 2205 2507 Stainless Steel Pipes Tubes PriceNegotiableMOQ: 1 Ton

-

Wholesale 201 304 316 Polished Round Stainless Steel Pipe Inox Manufacturer for Roofing Outdoor Decoration in ChinaNegotiableMOQ: 1 Ton

-

Factory Suppliers Prime Quality 304 304L 316 316L Stainless Steel Tube / Ss Pipe With Low PriceNegotiableMOQ: 1 Ton

-

304 Square Pipe Tp304 Stainless Steel Pipe 06cr19ni10 Welded Pipe 304L Sanitary Stainless Steel Seamless PipeNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Stainless Steel Square/Rectangular Pipe/Tube Ss Pipe 304 Stainless Steel TubeNegotiableMOQ: 1 Ton

-

High Quality Stainless Steel Square Tube, Rectangular Steel Tube Seamless Tube 304 316 321 Complete StockNegotiableMOQ: 1 Ton