ASTM AISI Corrision Resistant Stainless Steel Custom Size High Quality Stainless Steel Pipe

ASTM AISI Corrosion Resistant Stainless Steel Custom Size High - Quality Stainless Steel Pipe

Introduction

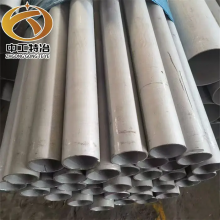

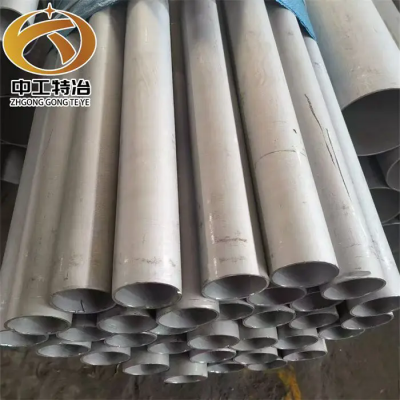

Our ASTM AISI corrosion - resistant stainless steel pipes are a pinnacle of engineering and quality in the world of metal products. Crafted with precision, these pipes are designed to meet the diverse and demanding needs of various industries across the globe. Whether it's for construction, industrial manufacturing, or any other application, our stainless steel pipes offer unparalleled performance and durability.

Material and Surface Treatment

Material

These pipes are made from high - grade stainless steel, adhering to the ASTM and AISI standards. The stainless steel composition provides excellent corrosion resistance, which is crucial for applications in harsh environments. The material is carefully selected and tested to ensure it meets the strictest quality requirements. It can withstand exposure to moisture, chemicals, and other corrosive substances, making it suitable for both indoor and outdoor use.

Surface Treatment

The pipes undergo a complete surface treatment process. This not only enhances their aesthetic appeal but also further improves their corrosion resistance. The smooth surface finish reduces the risk of debris accumulation and makes the pipes easier to clean and maintain. It also gives the pipes a professional and high - end look, which is important for applications where appearance matters.

Manufacturing Techniques

Hot Rolling and Cold Rolling

We utilize both hot rolling and cold rolling techniques in the manufacturing of these pipes. Hot rolling is used to shape the steel at high temperatures, which helps in achieving the desired dimensions and mechanical properties. It makes the steel more malleable and allows for the production of larger - sized pipes. Cold rolling, on the other hand, is employed to refine the surface finish and improve the precision of the pipes. It enhances the strength and hardness of the steel, resulting in pipes with superior quality and performance.

Custom Size Capability

One of the key features of our stainless steel pipes is the ability to offer custom sizes. We understand that different projects have different requirements, and a one - size - fits - all approach doesn't work. Our team of experts can work closely with customers to understand their specific needs and produce pipes in custom lengths, diameters, and wall thicknesses. This flexibility gives our customers the freedom to design and execute their projects without being limited by standard pipe sizes.

Quality Assurance

Production Certification

Our manufacturing process is certified under ISO 9001, which is a globally recognized quality management system. This certification ensures that every step of the production process, from raw material selection to the final product inspection, is carried out with the highest level of quality control. We have strict quality control measures in place to ensure that each pipe meets or exceeds the customer's expectations and industry standards.

Testing and Inspection

Each pipe undergoes rigorous testing and inspection before leaving our facility. We use advanced testing equipment to check for dimensional accuracy, mechanical properties, and corrosion resistance. This ensures that the pipes are of the highest quality and will perform reliably in their intended applications.

Applications

Construction

In the construction industry, our stainless steel pipes are used for structural support, plumbing systems, and decorative purposes. Their corrosion resistance and high strength make them ideal for building structures that need to withstand the test of time and environmental factors.

Industrial Manufacturing

For industrial manufacturing, these pipes are used in chemical processing plants, food and beverage production, and oil and gas industries. Their ability to resist corrosion and contamination is essential for maintaining the integrity of the production processes.

Other Applications

They are also used in marine applications, automotive manufacturing, and many other fields where high - quality, corrosion - resistant pipes are required.

Company Support and Service

Product Information and Sample Supply

We provide customers with detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality of our pipes. This allows customers to make informed decisions before placing an order.

Price and Negotiation

We offer a quotation based on customer needs, including price, delivery terms, and payment methods. We are open to price negotiation and strive to reach a mutually satisfactory price with our customers.

Order Processing

Once an order is placed, we accept and process it to ensure its accuracy and correctness. We confirm order details such as quantity, model, and delivery time, and keep the customers informed throughout the process.

Production Follow - up and Quality Control

We follow up on the production progress to ensure timely delivery. Our quality control team conducts regular inspections to ensure that the products meet the customer's requirements and standards.

Logistics Arrangement

We take care of the transportation and logistics, including shipping, transportation mode selection (sea freight, air freight, etc.), customs clearance, and other procedures. We track the transportation of goods to ensure smooth arrival at the customer's designated location.

After - Sale Service

We handle customer complaints and issues promptly to ensure customer satisfaction. Our customer service team is available 24/7 to assist customers with any problems they may encounter.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Pipe Manufacturer Stainless Steel 304 316l 904 Pipe 300 Series Alloy for IndustryNegotiableMOQ: 1 Ton

-

Factory Suppliers 201 304 304L 316 316L 430 436 439 409L 904L 310S 2205 2507 Stainless Steel Pipes Tubes PriceNegotiableMOQ: 1 Ton

-

Wholesale 201 304 316 Polished Round Stainless Steel Pipe Inox Manufacturer for Roofing Outdoor Decoration in ChinaNegotiableMOQ: 1 Ton

-

Factory Suppliers Prime Quality 304 304L 316 316L Stainless Steel Tube / Ss Pipe With Low PriceNegotiableMOQ: 1 Ton

-

304 Square Pipe Tp304 Stainless Steel Pipe 06cr19ni10 Welded Pipe 304L Sanitary Stainless Steel Seamless PipeNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Stainless Steel Square/Rectangular Pipe/Tube Ss Pipe 304 Stainless Steel TubeNegotiableMOQ: 1 Ton

-

High Quality Stainless Steel Square Tube, Rectangular Steel Tube Seamless Tube 304 316 321 Complete StockNegotiableMOQ: 1 Ton

-

Hot /Cold Rolled Stainless Steel/Gi Gl Seamless/Welde Square Steel Tube PipeNegotiableMOQ: 1 Ton

-

Square Rectangular Stainless Steel Tubes Hot Rolled 304 Square PipeNegotiableMOQ: 1 Ton

-

Factory Wholesale 304 316 321 430 Stainless Steel Seamless Pipe Elbow Square Pipe Full Size Email CommunicationNegotiableMOQ: 1 Ton