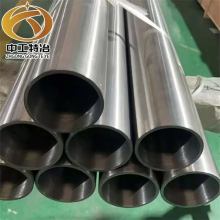

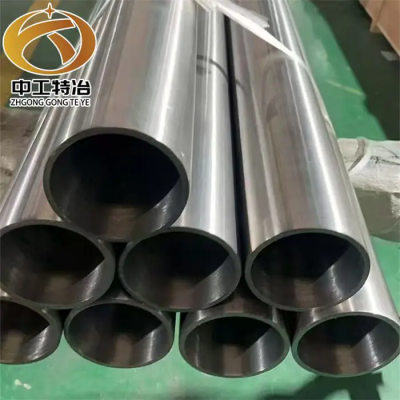

High Strength 316L Stainless Steel Pipe for Marine Engineering

Introduction

In the demanding realm of marine engineering, the choice of materials is crucial. Our High Strength 316L Stainless Steel Pipe stands as a premier solution, offering unparalleled durability and performance. This pipe is specifically engineered to meet the rigorous requirements of marine environments, where corrosion resistance, high strength, and reliability are of utmost importance.

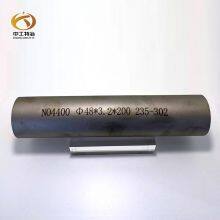

Material and Surface Treatment

- Material Composition: The 316L stainless steel used in our pipes is a low-carbon variant of 316 stainless steel. It contains molybdenum, which significantly enhances its corrosion resistance, especially in chloride-rich environments such as seawater. The low carbon content reduces the risk of carbide precipitation during welding, ensuring the integrity of the pipe's structure.

- Surface Treatment: The pipe undergoes a complete surface treatment process. This not only gives it a smooth and clean appearance but also further enhances its corrosion resistance. The surface finish helps to prevent the adhesion of contaminants and marine organisms, reducing the risk of biofouling and maintaining the pipe's performance over time.

Manufacturing Techniques

- Hot Rolling: Our pipes are initially formed through the hot rolling process. Hot rolling involves heating the steel billet to a high temperature and then passing it through a series of rollers to reduce its thickness and shape it into the desired pipe diameter. This process improves the mechanical properties of the steel, such as its strength and toughness, while also ensuring a uniform grain structure.

- Cold Rolling: After hot rolling, the pipes may undergo cold rolling for further refinement. Cold rolling is carried out at room temperature and allows for more precise control of the pipe's dimensions and surface finish. It also increases the pipe's hardness and strength, making it more suitable for high-pressure applications in marine engineering.

Key Features

- High Strength: Our 316L stainless steel pipes are designed to withstand high pressures and mechanical stresses. They have excellent tensile and yield strength, making them capable of handling the harsh conditions encountered in marine environments, such as strong currents, waves, and high hydrostatic pressures.

- Corrosion Resistance: One of the most significant advantages of 316L stainless steel is its outstanding corrosion resistance. The molybdenum content in the steel provides superior protection against pitting, crevice corrosion, and general corrosion in seawater. This ensures a long service life for the pipes, reducing the need for frequent replacements and maintenance.

- Weldability: The low carbon content of 316L stainless steel makes it highly weldable. It can be easily welded using various welding methods, such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding. This allows for seamless installation and connection of the pipes in marine engineering projects.

- Temperature Resistance: The pipes can maintain their mechanical properties over a wide range of temperatures. They can withstand both high and low temperatures, making them suitable for use in different marine applications, including offshore oil and gas platforms, desalination plants, and shipbuilding.

Applications in Marine Engineering

- Offshore Platforms: Our high-strength 316L stainless steel pipes are widely used in offshore platforms for transporting various fluids, such as seawater, oil, and gas. They are used in pipelines, risers, and other critical components, where their corrosion resistance and high strength are essential for the safe and efficient operation of the platform.

- Shipbuilding: In shipbuilding, these pipes are used in the ship's piping systems, including cooling systems, fire protection systems, and ballast systems. Their corrosion resistance helps to prevent leaks and damage to the ship's structure, ensuring the safety and reliability of the vessel.

- Desalination Plants: Desalination plants require pipes that can withstand the corrosive effects of saltwater and high-pressure operations. Our 316L stainless steel pipes are an ideal choice for these applications, as they can resist the aggressive environment and maintain their performance over time.

Company Support and Quality Assurance

- Product Information and Sample Supply: We are committed to providing our customers with detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality of our pipes before placing an order.

- Price and Negotiation: Our sales team will provide a quotation based on your specific needs, including price, delivery terms, and payment methods. We are open to price negotiation to reach a mutually satisfactory agreement.

- Order Processing: Once you place an order, our dedicated team will process it promptly, ensuring the accuracy of all order details, such as quantity, model, and delivery time.

- Production Follow - up and Quality Control: We closely follow up on the production progress to ensure timely delivery. Our quality control department conducts strict inspections at every stage of the manufacturing process to ensure that the pipes meet the highest industry standards and your specific requirements.

- Logistics Arrangement: We will arrange transportation and logistics for you, including shipping, selection of the appropriate transportation mode (sea freight or air freight), and customs clearance procedures. We will also track the transportation of the goods to ensure they arrive safely at your designated location.

- After - sale Service: Our customer service team is available to handle any complaints or issues you may encounter after the purchase. We are dedicated to ensuring your satisfaction and will do our best to resolve any problems promptly.

In conclusion, our High Strength 316L Stainless Steel Pipe is the ideal choice for marine engineering applications. With its excellent material properties, advanced manufacturing techniques, and comprehensive company support, it offers a reliable and long - lasting solution for your marine projects.

Send Inquiry to This Supplier

You May Also Like

-

Wholesale 201 304 316 Polished Round Stainless Steel Pipe Inox Manufacturer for Roofing Outdoor Decoration in ChinaNegotiableMOQ: 1 Ton

-

Factory Suppliers Prime Quality 304 304L 316 316L Stainless Steel Tube / Ss Pipe With Low PriceNegotiableMOQ: 1 Ton

-

304 Square Pipe Tp304 Stainless Steel Pipe 06cr19ni10 Welded Pipe 304L Sanitary Stainless Steel Seamless PipeNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Stainless Steel Square/Rectangular Pipe/Tube Ss Pipe 304 Stainless Steel TubeNegotiableMOQ: 1 Ton

-

High Quality Stainless Steel Square Tube, Rectangular Steel Tube Seamless Tube 304 316 321 Complete StockNegotiableMOQ: 1 Ton

-

Hot /Cold Rolled Stainless Steel/Gi Gl Seamless/Welde Square Steel Tube PipeNegotiableMOQ: 1 Ton

-

Square Rectangular Stainless Steel Tubes Hot Rolled 304 Square PipeNegotiableMOQ: 1 Ton

-

Factory Wholesale 304 316 321 430 Stainless Steel Seamless Pipe Elbow Square Pipe Full Size Email CommunicationNegotiableMOQ: 1 Ton

-

Astm Standard Stainless Steel Pipe 316l Tube Stainless Steel Seamless Round PipeNegotiableMOQ: 1 Ton

-

High Precision Alloy Round Auto Accessories China Stainless Steel Tube 304/316LNegotiableMOQ: 1 Ton