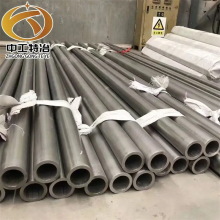

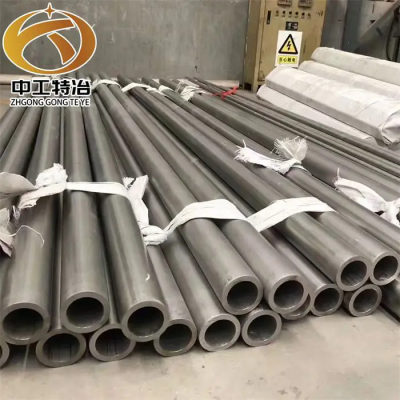

Stainless Steel Pipe Manufacturer Stainless Steel 304 316l 904 Pipe 300 Series Alloy for Industry

Introduction to Our Stainless Steel Pipes

Our company specializes in manufacturing high - quality stainless steel pipes, offering a wide range of options including Stainless Steel 304, 316L, and 904 pipes from the 300 series alloy, specifically designed for industrial applications. These pipes are crafted with precision and adhere to the highest quality standards, ensuring durability and performance in various industrial environments.

Material and Composition

Stainless Steel 304: This is one of the most commonly used grades in our stainless - steel pipe range. It contains approximately 18% chromium and 8% nickel. The high chromium content provides excellent corrosion resistance, while the nickel enhances the pipe's formability and toughness. In industrial settings, it can withstand mild corrosive environments, making it suitable for applications such as food processing, beverage production, and general construction.

Stainless Steel 316L: With a composition of about 16 - 18% chromium, 10 - 14% nickel, and 2 - 3% molybdenum, the 316L grade offers superior corrosion resistance compared to 304. The addition of molybdenum makes it highly resistant to pitting and crevice corrosion, especially in chloride - rich environments. It is often used in marine applications, chemical processing plants, and pharmaceutical industries.

Stainless Steel 904: This is a super - austenitic stainless steel with a high nickel (23 - 28%), chromium (19 - 23%), and copper (1 - 2%) content. It provides excellent resistance to a wide range of corrosive substances, including sulfuric acid, phosphoric acid, and many organic acids. In industries where exposure to harsh chemicals is common, such as the chemical and petrochemical sectors, 904 pipes are the ideal choice.

Manufacturing Process

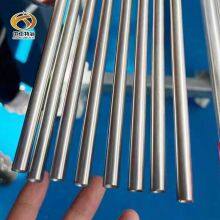

Hot Rolling and Cold Rolling: Our pipes are manufactured using both hot - rolling and cold - rolling techniques. Hot rolling is used to initially shape the steel into rough pipe forms. This process involves heating the steel above its recrystallization temperature and passing it through rollers. It allows for the production of large - diameter pipes with a relatively thick wall. Cold rolling, on the other hand, is used to further refine the pipes. It improves the surface finish, dimensional accuracy, and mechanical properties of the pipes. The cold - rolled pipes have a smoother surface and tighter tolerances, which are crucial for many industrial applications.

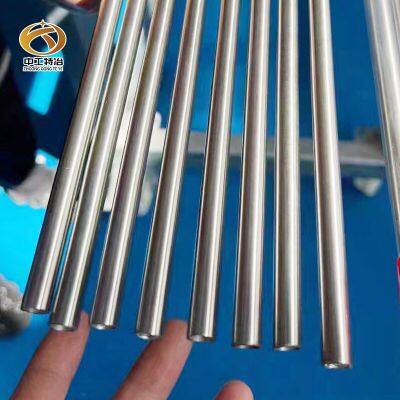

Surface Treatment: Each pipe undergoes a complete surface treatment process. This includes pickling, passivation, and polishing. Pickling removes any scale or impurities from the pipe's surface, while passivation forms a protective oxide layer that enhances corrosion resistance. Polishing gives the pipes a smooth and aesthetically pleasing finish, which is not only important for appearance but also helps in reducing friction and preventing the accumulation of contaminants.

Product Features

Strength and Durability: Our stainless - steel pipes possess high strength and can withstand high - pressure and high - temperature conditions. They are designed to have a long service life, reducing the need for frequent replacements in industrial operations. This durability translates into cost savings for our customers in the long run.

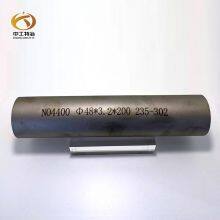

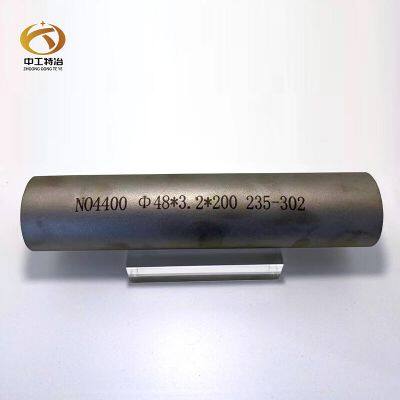

Dimensional Accuracy: We ensure strict control over the dimensions of our pipes. The outer diameter, wall thickness, and length of each pipe are precisely measured and meet international standards. This dimensional accuracy is essential for proper installation and connection in industrial systems, ensuring a leak - free and efficient operation.

Versatility: The 300 series alloy pipes can be used in a wide variety of industrial applications. Whether it's for transporting fluids, gases, or as structural components, our pipes can adapt to different requirements. They can be easily welded, bent, and fabricated according to specific project needs.

Quality Assurance

ISO 9001 Certification: Our manufacturing process is certified under the ISO 9001 quality management system. This means that every step, from raw material sourcing to the final product inspection, is carefully monitored and controlled. We conduct regular quality audits to ensure that our products consistently meet or exceed customer expectations.

Testing and Inspection: Each pipe undergoes a series of rigorous tests, including non - destructive testing such as ultrasonic testing and magnetic particle inspection to detect internal and surface defects. We also perform mechanical property tests such as tensile testing and hardness testing to ensure that the pipes have the required strength and toughness.

Applications

Chemical Industry: In chemical plants, our stainless - steel pipes are used to transport various chemicals, acids, and alkalis. The corrosion - resistant properties of these pipes ensure the safe and efficient transfer of these substances without the risk of leakage or contamination.

Oil and Gas Industry: For oil and gas exploration, production, and refining, our pipes can handle high - pressure and high - temperature fluids. They are used in pipelines, wellheads, and refinery equipment, where reliability and performance are of utmost importance.

Food and Beverage Industry: The hygienic properties of our stainless - steel pipes make them suitable for food and beverage processing. They can be used for conveying liquids, such as milk, juice, and beer, without imparting any taste or odor to the products.

Company Background

We are Jiangsu Zhonggongte Metallurgical Technology Co., Ltd., a manufacturer established in 2022. With a rich history dating back to 1999, when we opened our first metal - material sales office in Beijing, we have gradually expanded our business. In 2011, we set up a second office in Tianjin for stainless - steel material sales. Since 2012, we have been involved in the research and sales of non - ferrous metals, including nickel - based alloys, Hastelloy alloys, and titanium alloys. Our company has an overseas office and an export share of above US$100 million, with a team of 21 - 50 salespeople. We serve major markets across the globe, including North America, South America, Europe, Asia, Africa, and Oceania.

Company Services

Product Information and Sample Supply: We provide customers with detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality of our pipes before placing large - scale orders.

Price and Negotiation: Based on customer needs, we provide quotations that include price, delivery terms, and payment methods. We are open to price negotiations to reach a mutually satisfactory agreement.

Order Processing: Once we receive a customer order, we process it carefully to ensure accuracy. We confirm order details such as quantity, model, and delivery time to meet customer requirements.

Production Follow - up and Quality Control: We closely follow up on the production progress to ensure timely delivery. At the same time, we conduct strict quality control throughout the manufacturing process to guarantee that the pipes meet customer requirements and standards.

Logistics Arrangement: We take care of all transportation and logistics aspects, including shipping, selecting the appropriate transportation mode (sea freight or air freight), and handling customs clearance procedures. We also track the transportation of goods to ensure they arrive smoothly at the customer's designated location.

After - Sale Service: Our dedicated after - sale service team handles customer complaints and issues promptly. We are committed to ensuring customer satisfaction and maintaining long - term relationships with our clients.

Company Team

Technical Team: Our technical team consists of numerous sales elites who are proficient in the specialized knowledge of special alloys. They can quickly explain the professional knowledge of our products to customers and are constantly working on promoting product iteration and upgrading.

Market and Sales Team: Composed of experienced marketing and sales elites, this team accurately grasps market dynamics and effectively expands our market share.

Customer Service Team: With a customer - centered approach, the customer service team provides 24 - hour uninterrupted high - quality service. They are always ready to assist customers and ensure continuous improvement in customer satisfaction.

Innovation and Collaboration: We encourage our team members to be innovative, have the courage to try new things, and constantly explore new resources and customers. We also emphasize teamwork, promoting cross - departmental communication and collaboration to jointly solve problems.

Learning and Responsibility: We have established a learning organization where employees are encouraged to continue learning to enhance their individual and team abilities. Every team member is responsible to customers, the company, and society, ensuring that every task meets the highest standards.

If you are interested in our stainless - steel pipes, please feel free to contact us. You can reach us via email at zhonggongte@qq.com, WhatsApp at +8613306184668, or visit our company located in Xinwu District. Our sales representative Zhou will be happy to assist you with any inquiries.

Send Inquiry to This Supplier

You May Also Like

-

High Quality Stainless Steel Square Tube, Rectangular Steel Tube Seamless Tube 304 316 321 Complete StockNegotiableMOQ: 1 Ton

-

Hot /Cold Rolled Stainless Steel/Gi Gl Seamless/Welde Square Steel Tube PipeNegotiableMOQ: 1 Ton

-

Square Rectangular Stainless Steel Tubes Hot Rolled 304 Square PipeNegotiableMOQ: 1 Ton

-

Factory Wholesale 304 316 321 430 Stainless Steel Seamless Pipe Elbow Square Pipe Full Size Email CommunicationNegotiableMOQ: 1 Ton

-

Astm Standard Stainless Steel Pipe 316l Tube Stainless Steel Seamless Round PipeNegotiableMOQ: 1 Ton

-

High Precision Alloy Round Auto Accessories China Stainless Steel Tube 304/316LNegotiableMOQ: 1 Ton

-

Manufacturer Supplier Hot Rolled Cold Stainless Alloy Alloy Mild Steel Ss Boiler Square TubeNegotiableMOQ: 1 Ton

-

Factory Price Stainless Steel Pipes 304/316L Seamless Pipe Stainless Steel Pipe TubeNegotiableMOQ: 1 Ton

-

Stainless Steel Alloy Steel Seamless Pipe/Tube Used for Heat Exchanger, Oil, GasNegotiableMOQ: 1 Ton

-

China Supplier 304, 304L, 321, 316L, 317L Square Hollow Steel TubeNegotiableMOQ: 1 Ton